METALMAQ gives an online course to 40 students from CIFP SOMESO in A Coruña (Galicia-Spain).

Professor José Ramón Lamas contacted us so that we could give an Online course on press brake tools to his students.

COURSE STRUCTURE

Bearing in mind that the two student courses have different levels and that they are students of the WELDING AND BOILER WORKING module, the idea was that the course would be structured through our ONLINE SHOP, since that way the students could consult it after the talk (it is difficult to assimilate all the technical concepts in two hours and, therefore, the best option is to give a good explanation teaching how to use our ONLINE SHOP and use it as a reference tool).

The course was structured as follows:

– DEFINITION OF THE PUNCH MOORING

The punch is the upper part of the tool housed in the press brake where the metals sheet is shaped.

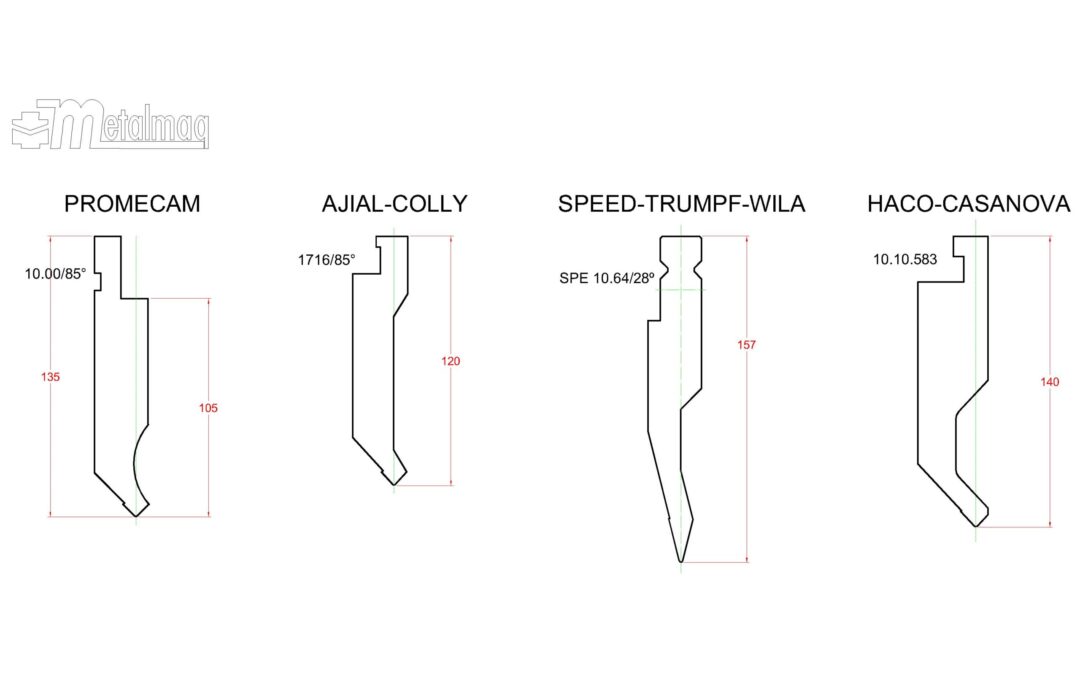

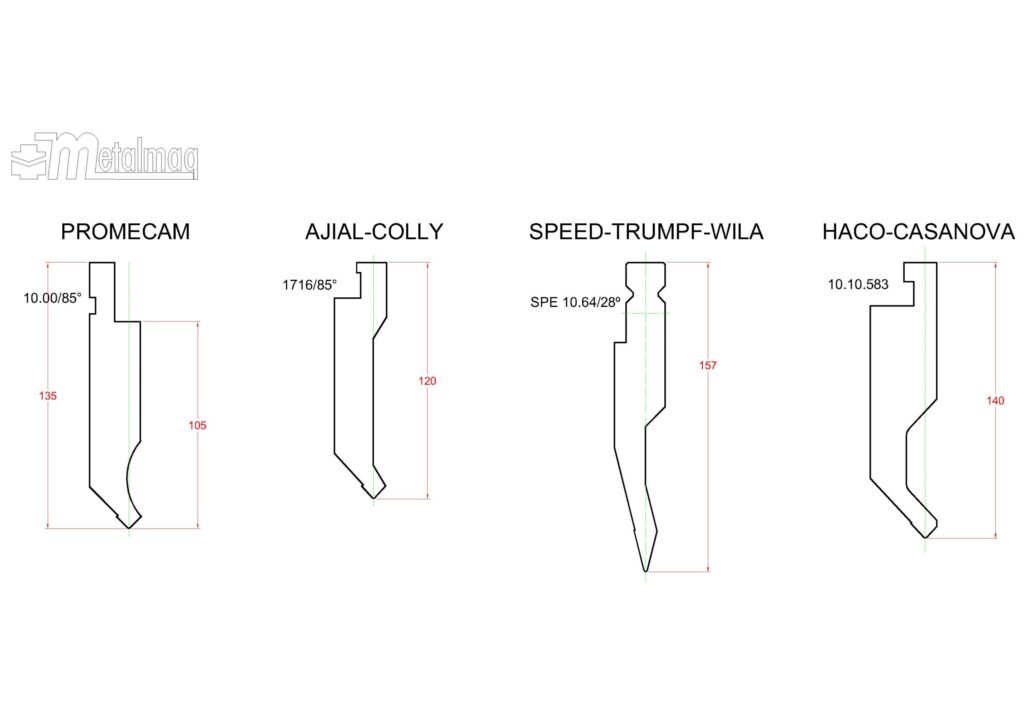

The first thing we must define is what type of mooring our press brake has (that is to say, the mooring it has to be fastened) and for this reason we explain through the Online Shop (see link) the most common moorings used in Spain. In the following sketch we can see the most usual.

The first mooring is called PROMECAM, it is one of the most common in the world and is characterized by the fact that the bend line (marked in green) is in the second step of the mooring, this is important since the line of the bend must always be well aligned so as not to cause accidents and damage the punch. The anti-fall system is made with a small slot (it is located where the reference 10.00/85º).

The second mooring is the AJIAL-COLLY type, it is very common in Spain and France, but little used in the rest of the world. The bend line is centered on the axis of the punch and the anti-fall system is made through a protruding flange.

The third mooring is the SPEED system or also known as the TRUMPF system or the WILA system, the center of the bend is also centered on the axis of the punch and its mooring system is made by means of pins that it has on the upper part or it can also be done by means of the “Safety-Klick” button. This system is installed, among others, by press brakes Trumpf, Bystronic, Lvd and Axial.

Finally, the HACO-CASANOVAS system has characteristics similar to the AJIAL-COLLY system, but the mooring measurements are different.

There are many more types of mooring, but the most “standardized” are usually the exposed ones.

– DEFINITION OF THE SHAPE OF THE PUNCH

Once we have defined the type of punch mooring we need, we have to ask ourselves how we want it. The easiest thing is to see what kind of work we need it for.

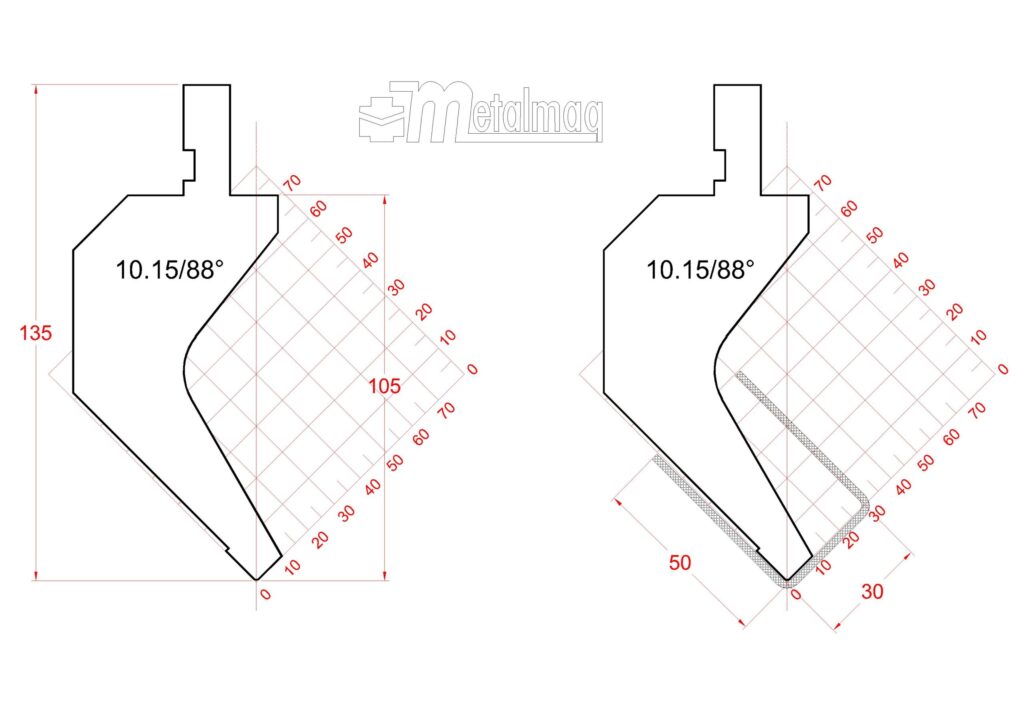

All the punches that can be seen in our ONLINE SHOP have an overlying grid (you can download all the PDF plans inside each punch to see the more defined grid). This grid will give us a clue as to what the chosen punch can bend.

We are going to put an example; if we have to bend a “U” shaped metal sheet of 50 x 30 x 50 m/m, in 2 m/m thickness and our mooring system is PROMECAM, we could choose the punch mod. 10.15/88º (in shape of a “goat’s foot”). As we can see in the attached sketch, the left-hand punch is the commented model and has the attached grid. On the right side we see how the “U” shaped sheet has been drawn on the punch and, as we do NOT see any collision, we conclude that it is the perfect punch to do this job.

– DEFINITION OF THE MOORING OF THE DIE

The die is the lower part of the tool that is placed in the press brake where the metal sheet is shaped.

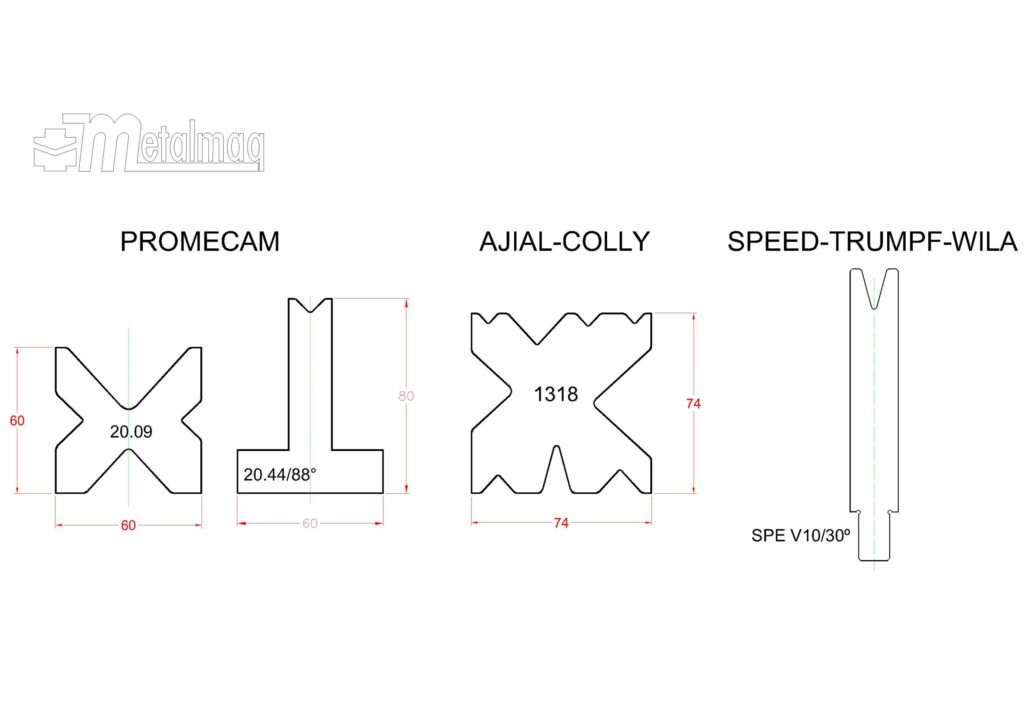

Like the punch, the first thing we must define is what type of mooring our press brake has in the die and for this we explain through the Online Shop (see link) the most common moorings that are used worldwide. In the following sketch we can see the most usual.

The first two are from the PROMECAM system, they are supplied in sections of 835 m/m and 415 m/m and are characterized in that their “vees” are always centered on the bend axis. It is one of the most manufactured systems.

The third die is the AJIAL-COLLY and they are supplied in the entire length that the press brake has (1, 2, 3, 4 and up to 6 meters in a single piece), its “vees” are not centered in the die, since it is characterized by the fact that when changing the “vee” it must be centered each time in the bend center of the press brake.

The third system is known as SPEED, TRUMPF or WILA, it is manufactured in 500 m/m sections, this system has a 20 x 13 m/m mooring at the bottom that is placed in one location and tied to the press brake manually or through a hydraulic fast-clamping system. It is very common in Trumpf, Bystronic, Lvd and Axial brand press brakes.

– DEFINITION OF THE TYPE OF DIE

What will define the type of die or “ve” to use is going to be the thickness of the metal sheet to be folded, in this link of the BENDING TABLE you can see how to choose the appropriate “ve” and you can also see two practical examples.

BENDING SOLUTIONS

Within our ONLINE SHOP we have a BLOG-COMPANY section and within this section we will find a sub-section that we call BENDING SOLUTIONS.

In this section you can see several very interesting POST about;

– BENDING TABLE, is the basis for knowing how to use the right tools.

– HARDOX AND WELDOX MATERIAL, increasingly used, are high-strength materials that require different dies and tools from the usual ones.

– CALCULATION OF THE DEVELOPMENT OF A METAL SHEET, is the most consulted section and teaches through formulas and definitions how to calculate the development of a metal sheet.

– HOW TO BEND LARGE RADIOS? It teaches what must be taken into account to bend with larger radii than usual.

– HOW TO AVOID FOLDING MARKS? In a world where quality is higher every day, this is an essential POST.

There are several more POSTs and each year they are added as questions and new challenges arise in the metal deformation sector. It is a good tool to clarify doubts.

ACCESSORIES FOR PRESS BRAKE

We manufacture many accessories to facilitate work on the metal sheet press brake, from protective films to avoid marking on the metal sheet, LASER LINE to align marked sheets, manual and magnetic front squares to align small parts, back gauge for manual and electric bending machines and many more products. In this link you can see all our manufacturing offer; https://metalmaq.shop/en/13-accessories-press-brake

QUESTION TIME

Some students asked several very interesting questions, including highlighting their curiosity and then our explanation of the success of our ONLINE SHOP, especially in markets as far away as the USA and Canada.