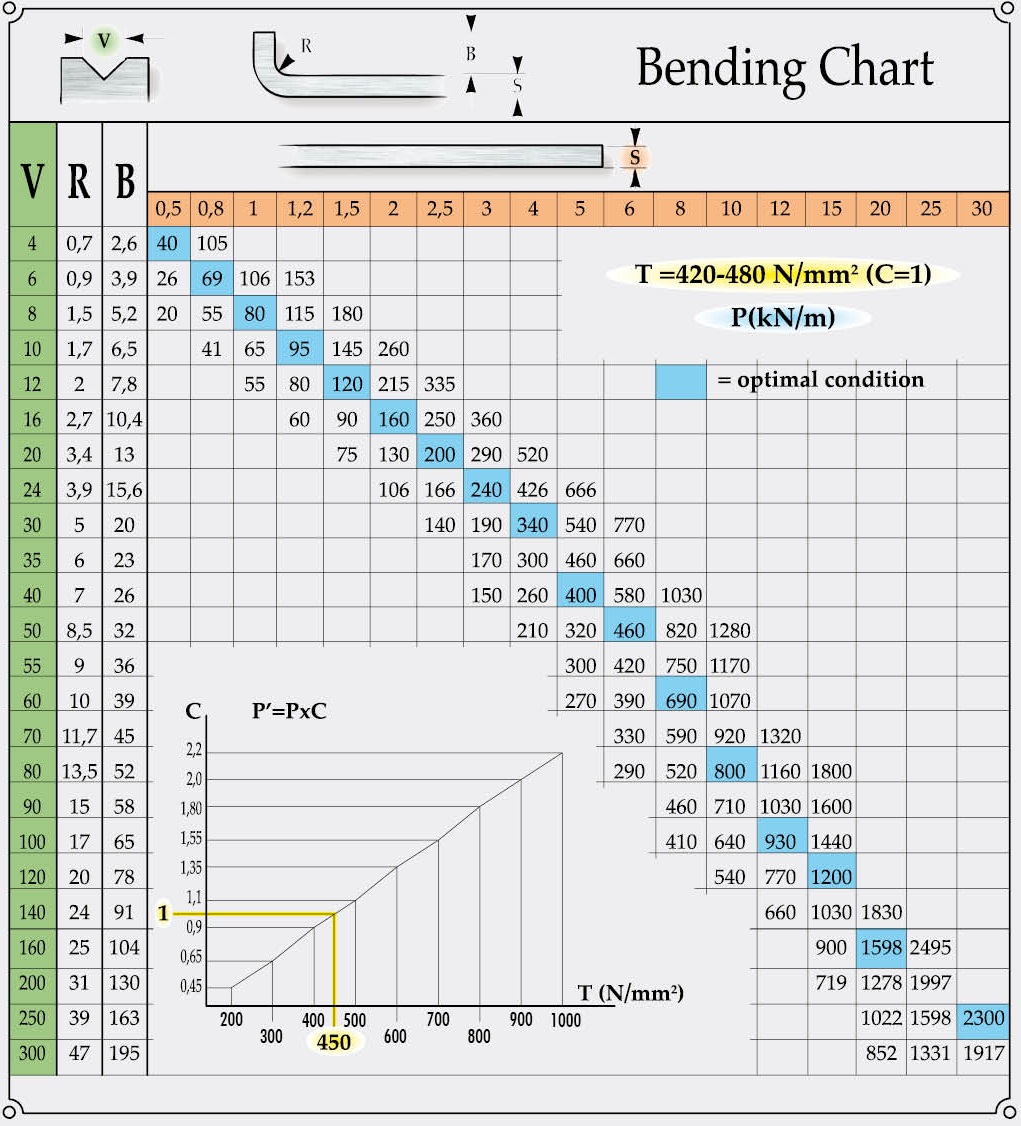

The METAL SHEET BENDING TABLES are the basis of knowledge or operation to use the appropriate tools in the bending process, nowadays in the electronic press brakes of last generation usually there are not installed the BENDING TABLES, since the current numerical controls do all these functions automatically, but it is fundamental to know them, to learn the concept of bending the BENDING TABLE will be of great help.

Concepts to be taken into account

We must be clear that the measure of the die, that is to say the V, we will choose it by the thickness of the metal sheet to be bended (in the past it used to be said that multiplying the thickness by 8 gives us the appropriate “V”, for example in the thickness of 2 m/m x 8 = 16 will be the appropriate “V” and the truth is that the “trick” works!). The tonnage comes marked by the installed “V”, that is to say with less “V” we will need more Tonnage and to more “V” less Tonnage, obviously if the material is harder (as in the case of Stainless) more Tonnage we need. As for the internal radius of the metal sheet (by the physical law of the material) the internal radius of the metal sheet will be at least the thickness of it, that is to say, in a sheet of 3 m/m the internal radius will be at least 3 m/m and with more V it will have more inner radius (and outside, obviously). The minimum “wing” is marked by the size of the “V”, if we put a “V” of 50 m/m the minimum “wing” will be 25 m/m (which is half of 50 m/m) plus the input radius of the “V”, plus a little margin so that when bending the metal sheet does not enter inside the “V” at the first moment. At the end we will have a minimum “wing” of 32 m/m.

BENDING TABLES of a Press Brake MEBUSA, a Press Brake LVD and a Press Brake AMADA-PROMECAM, respectively.

Practical exercises

Having seen these concepts and based on our BENDING TABLE, we propose two examples to put into practice what has been said previously

EXEMPLE 1 for metal sheet bending tables

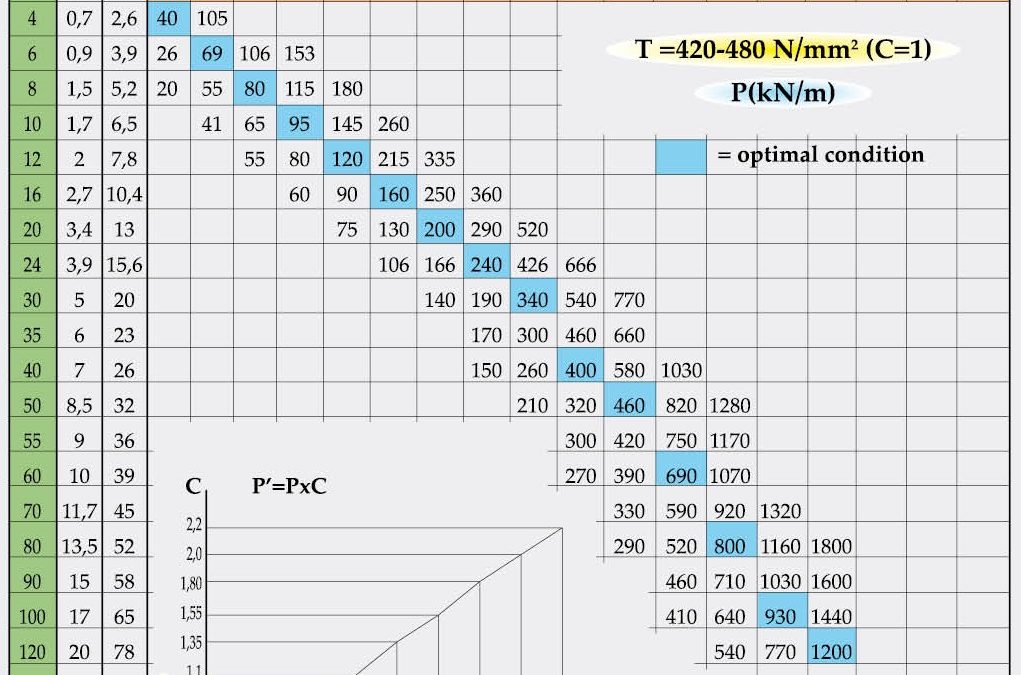

We have a metal sheet of 3 m/m thickness in iron (with a hardness of 42-48Kg / mm2), if we go to the top of the table we see the thicknesses in brown, we look at the 3 (thickness of the sheet ) and we go down to the blue box, we see a value of 240, this is in KN/mm2 and if we take a 0 it will be in Ton/mt, that is to say it will be 24Ton per meter the force needed to bend in sheet of 3 m/m with a V of 24 m/m (value in green if we follow the line horizontally). Next to the V it also indicates the internal radius that will leave the metal sheet, in this case 3.9 m/m of interior radius and we will also see the minimum internal wing that we can leave, in this case it will be 15,6 m/m .

If for us the minimum wing is too large, we can see how much we can decrease the V to reduce it. If we lower the line of the thickness of 3 m/m we see the value of 360Kn/mm2, which is equal to 36Ton/mt, if we use a V of 16 m/m (go horizontally to the green box “V”) and there we see that it will leave an internal radius of 2,7 m/m and we can make a minimum wing of 10,4 m/m.

EXEMPLE 2 for metal sheet bending tables

We have a metal sheet of 5 m/m thickness in INOX (with a hardness of 70Kg/mm2), in this case we must look at the small square inserted in the table. We observe in the lower part the value T (N/mm2), the hardness of this material is 700 N/mm2, that is to say 70Kg/mm2, if we go to the C value it gives us 1,55, this will be the value that we will multiply in the tonnage (blue color).

Let’s go back to the sheet of 5 m/m INOX, if we go to the top of the table we see the thicknesses (brown color), we look at the 5 (thickness of the metal sheet) and go down to the blue box, we see a value of 400, this is in KN/mm2 and if we take a 0 will be in Ton/mt, that is to say it will be 40 Ton that we will multiply by 1,55 (value taken from the small table), this gives us 62 Ton per meter the force required to bend in sheet of 5 m/m of INOX with a V of 40 m/m (value in green if we follow the line horizontally). Beside it also indicates us the inner radius that will leave the metal sheet, in this case 7 m/m of inner radius and we will also see the minimum inner wing that we can leave, which will be 26 m/m.

Thank you very much for your comment!!

I want to know how many minimum inside radius is to be required to bend so no crack, deformation and crack not develop on bending radius portion. If any formula PL. Send on my mail.

To give you better advice you should know; What is the thickness of sheet metal and what type of materail is it?

Remember that the inner radius that is left on a sheet is at least equal to the thickness of the same or somewhat higher