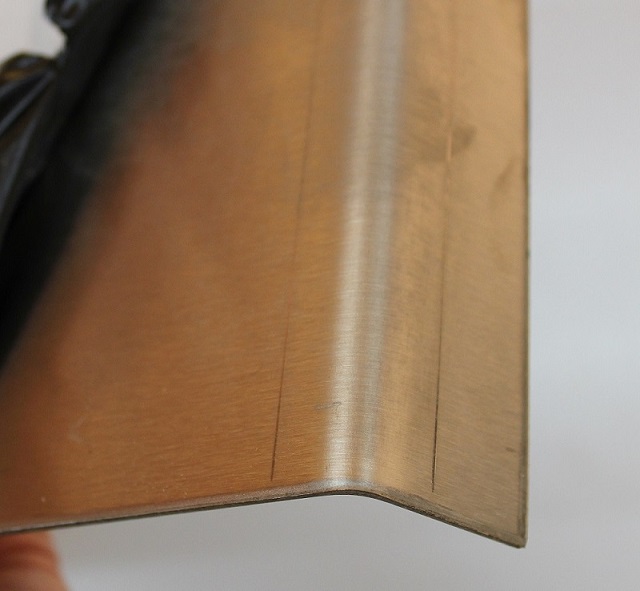

Stainless steel sheet of 3 m/m with protection, with marks

Stainless steel sheet of 3m/m with bending marks

Stainless steel sheet of 3 m/m without bending marks

In the 21st century, it is no longer necessary to say how important quality is in all the products that are manufactured today. And, as it could not be otherwise, also in the metal sheet bending phase the quality and absence of marks is not important, but essential.

But there are still many customers who ask us how to avoid those marks. And not only for its aesthetic function but also for regulations (especially in the food sector), since when bending a stainless steel sheet, even if it has protection, if it is marked, it not only causes an aesthetic deterioration, but also causes a contamination of the bended stainless steel, since the ferric particles adhered to the die pass to the bended stainless steel, being very deep and sometimes even after a polishing operation of the sheet, these particles remain in the stainless, passing unnoticed …… but once installed the stainless steel sheet and after several months, reacting with some liquid element (such as water), a rust strip appears and provoking the customer’s alarm.

In the end, if we want the stainless steel sheet to be neither marked nor contaminated, the protective film with which it was supplied must remain intact after folding.

To avoid the marks we propose three solutions that are the most common and used. We present them in order of importance :

1.- SOLUTION: Protective films

This solution is the most common due to its low cost, also because you can take advantage of all the tools that we already have in the press brake.

Metalmaq supplies three types of protective films and thus we have an adequate solution for each type of material and for each type of customer;

GOMA USA 0,5 m/m

Goma USA 0,5 m/m, protective film “free marks”

Goma USA 0,5 m/m, protective film “free marks”

Goma USA 0,5 m/m, protective film “free bending marks”

It is the most sold for its extraordinary QUALITY / PRICE ratio. The duration depends on the bending angle, the burr of the sheet, the thickness and type of material to be bended, etc., but roughly its average duration is as follows;

- INOX sheet of 1 m/m: about 500 bends, then the protective film can be moved perpendicularly and multiply these bends by 5

- INOX sheet of 2 m/m: about 300 bends, then the protective film can be moved perpendicularly and multiply these bends by 4

- INOX sheet 3 m/m: about 150 bends, then the protective film can be moved perpendicularly and multiply these bends by 3

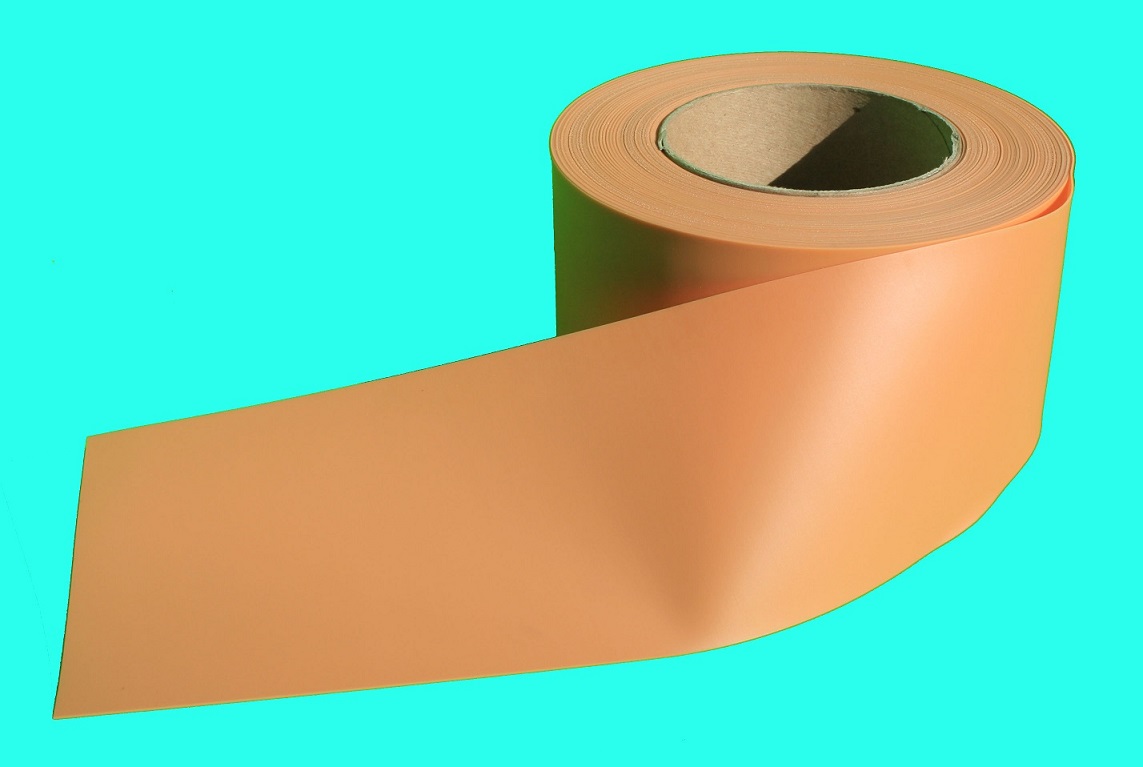

GOMA POLYURETHANE 0,8 m/m

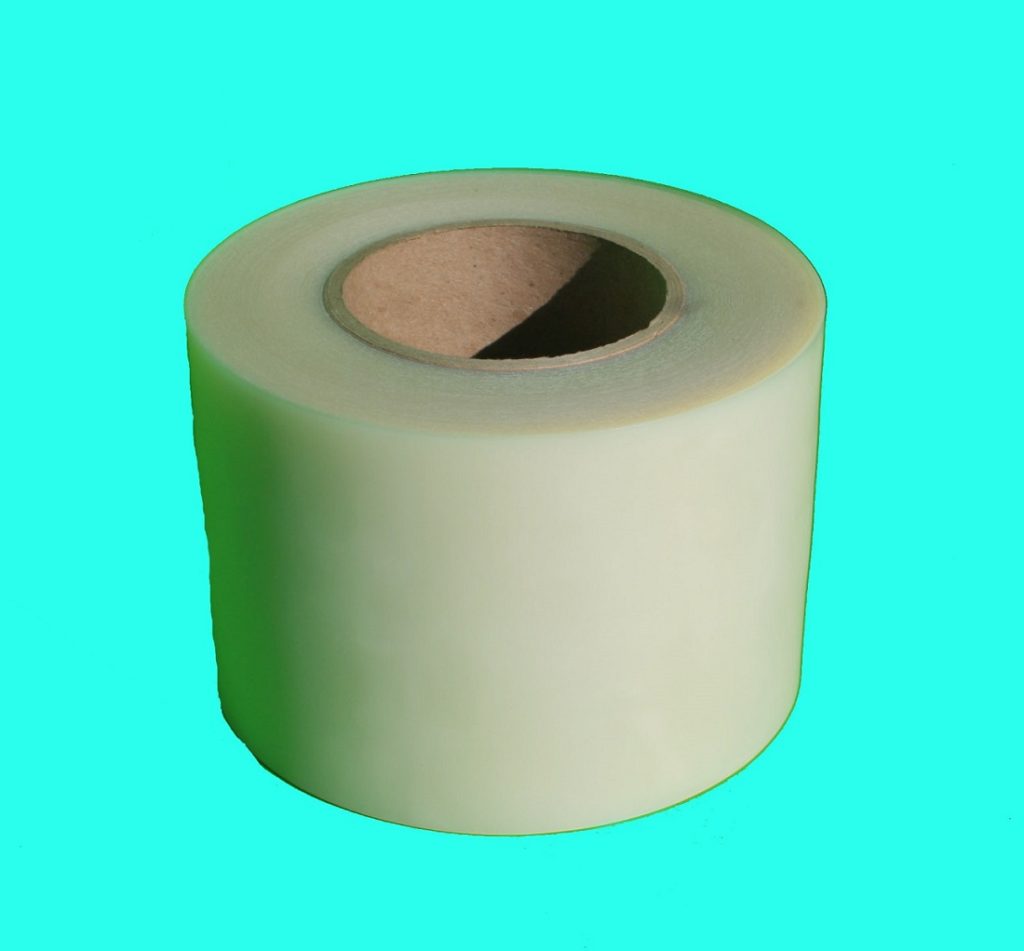

Goma Polyurethane 0,8 m/m, protection free marks

Roll of Goma Polyurethane 0,8 m/m, free marks

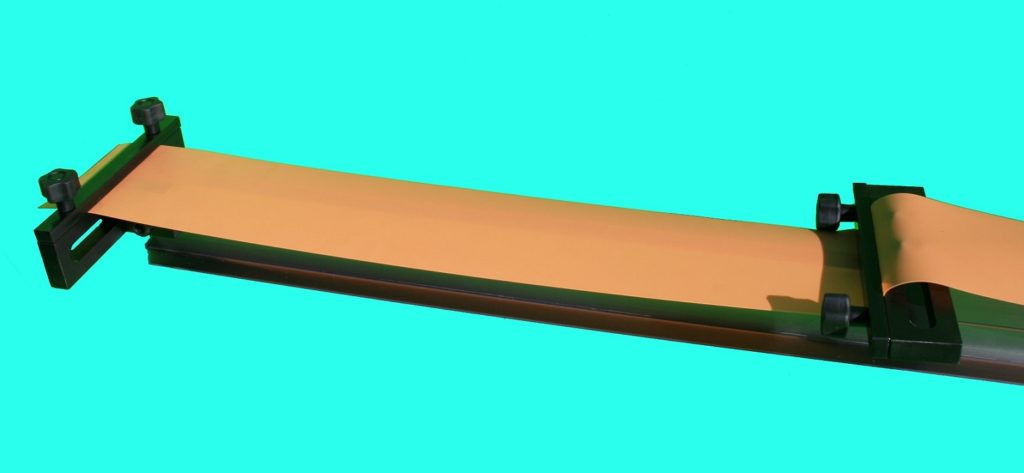

Installation on die of Goma Polyurethane 0,8 m/m

It is the one that continues in sales (with a ratio of 1 to 10), it lasts less than the GOMA USA, but in certain applications and with thicker thicknesses it is better.

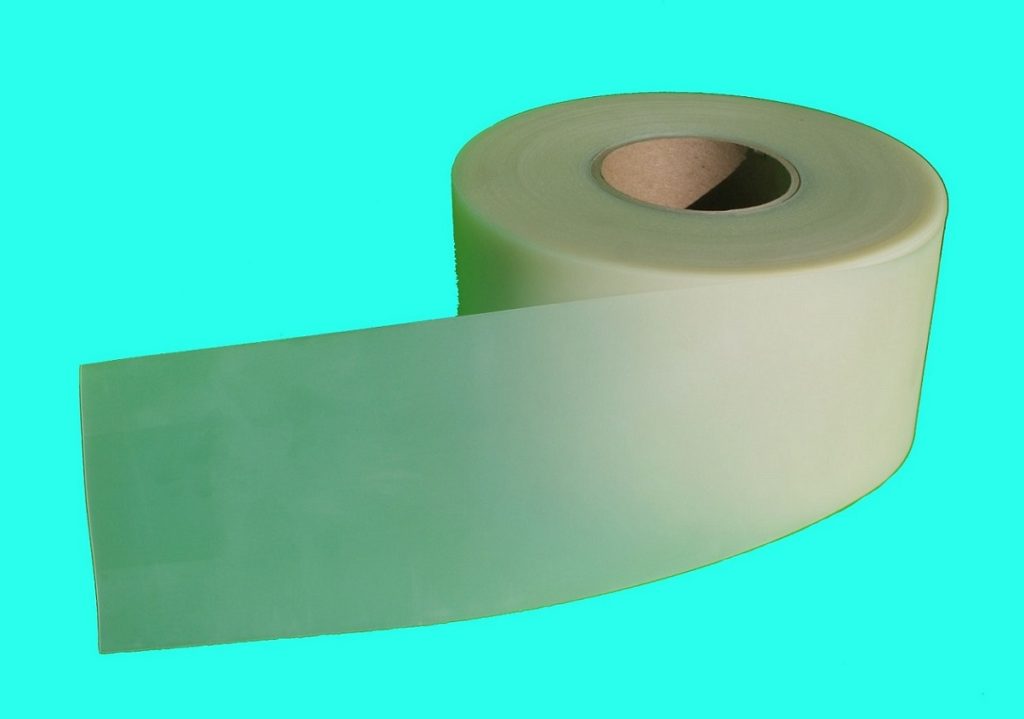

GOMA POLYURETHANE 0,4 m/m

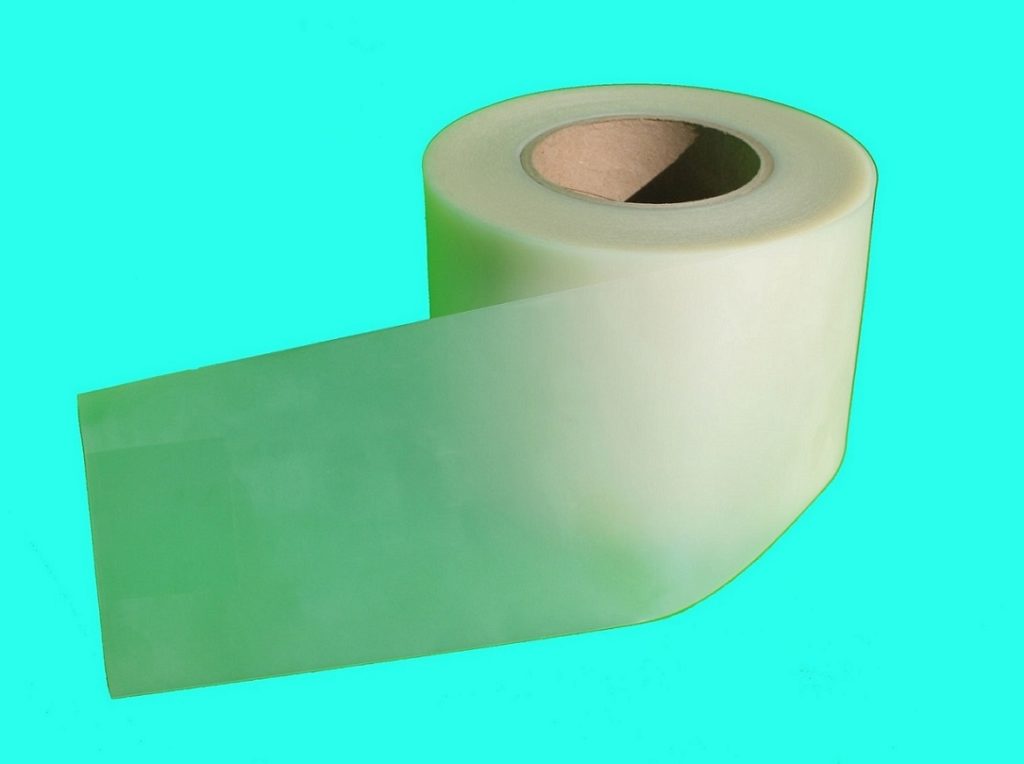

Protective film Goma Polyurethane 0,4 m/m

Roll of Goma de Polyurethane 0,4 m/m, to avoid marks

Installation on die of Goma Polyurethane 0,4 m/m

It is sold for its excellent price and for those customers who use it occasionally.

In the following video you can clearly see the three types of Protective Films;

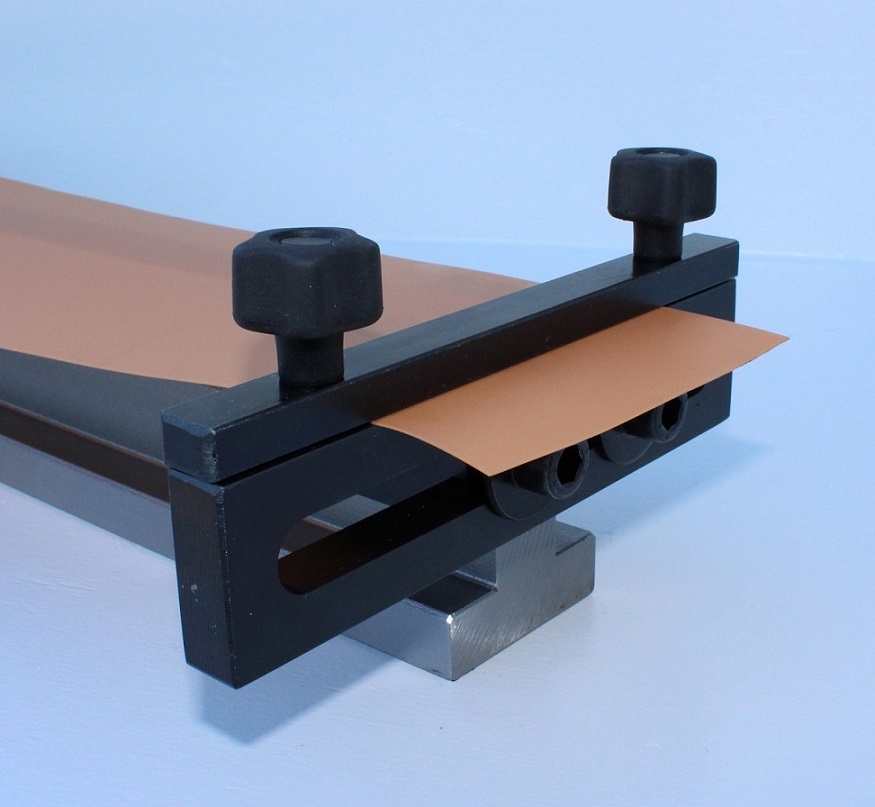

To use the Protective Films well and to make it last many bends, we propose two types of supports;

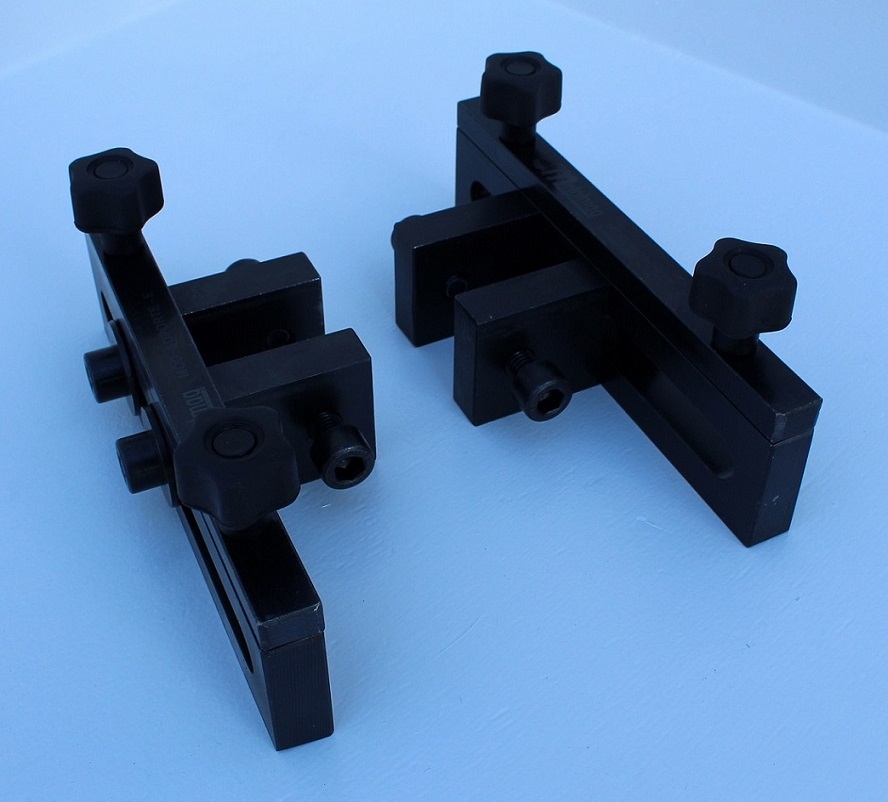

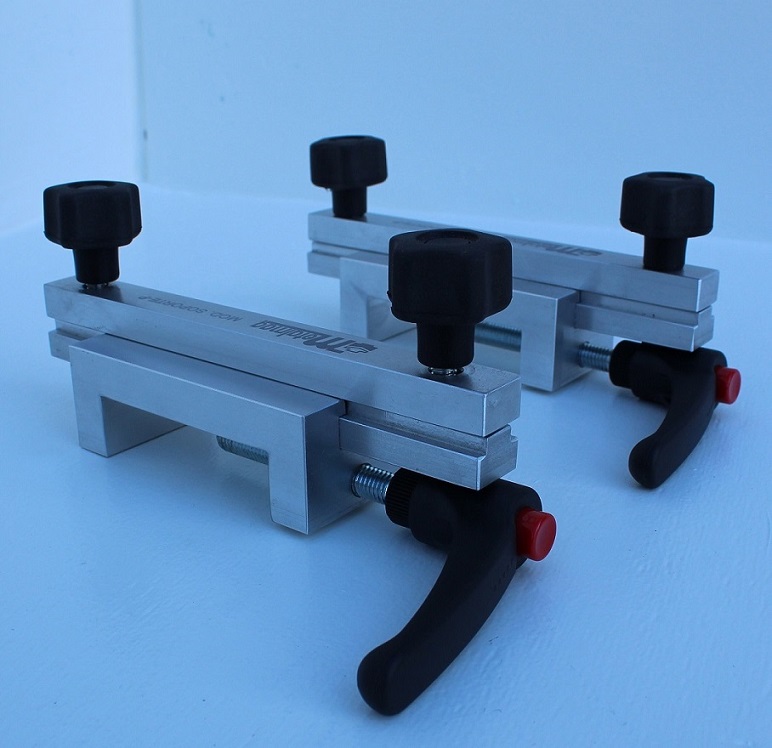

SUPPORT-E

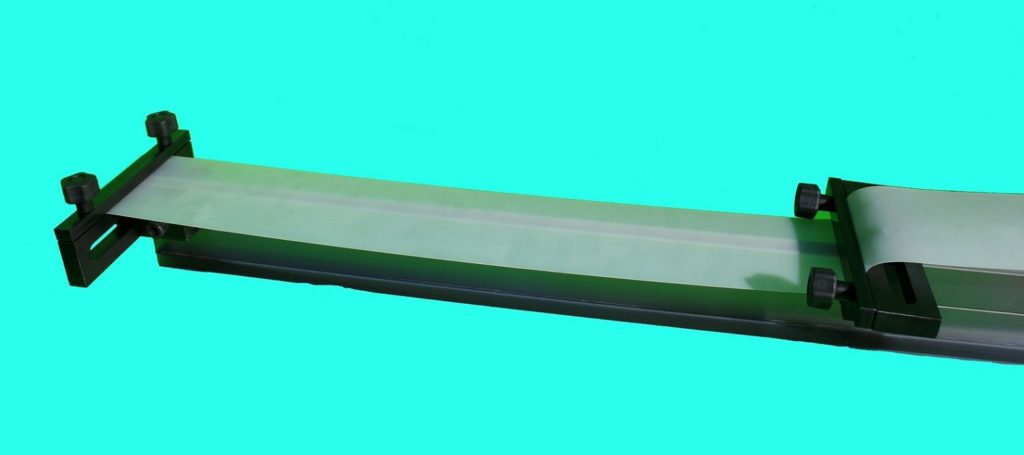

Support-E for Protective Film “free marks”

Support-E for Protective Film “free bending marks”

Support-E installed in a press brake die

For dies up to a maximum of 112 m/m width and adjustable to them with screws.

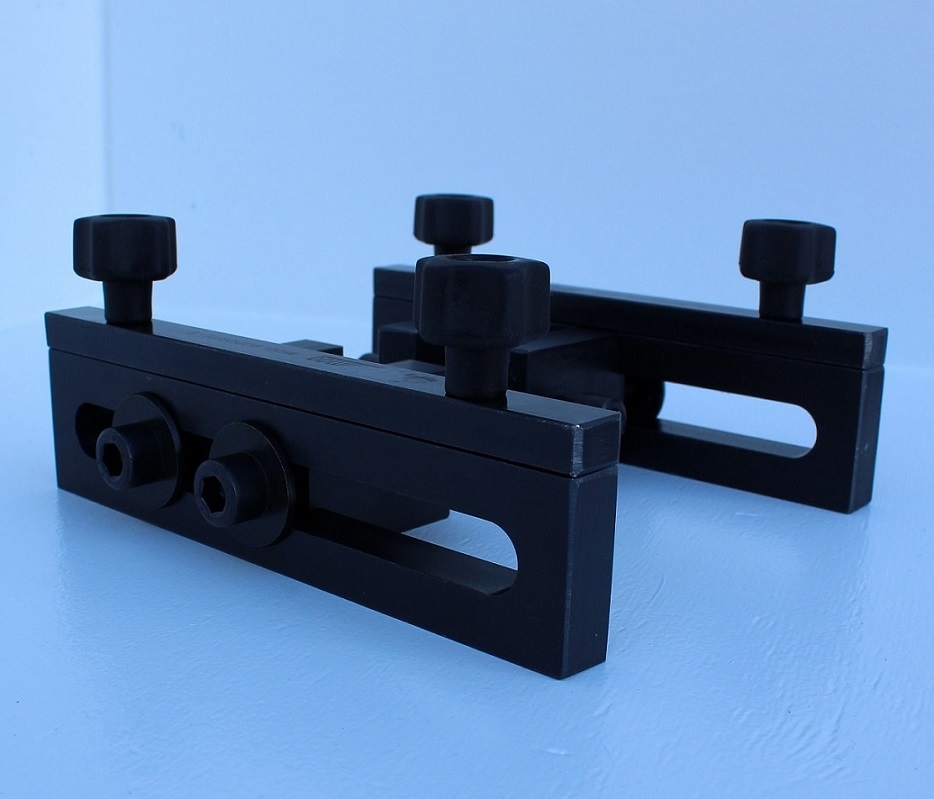

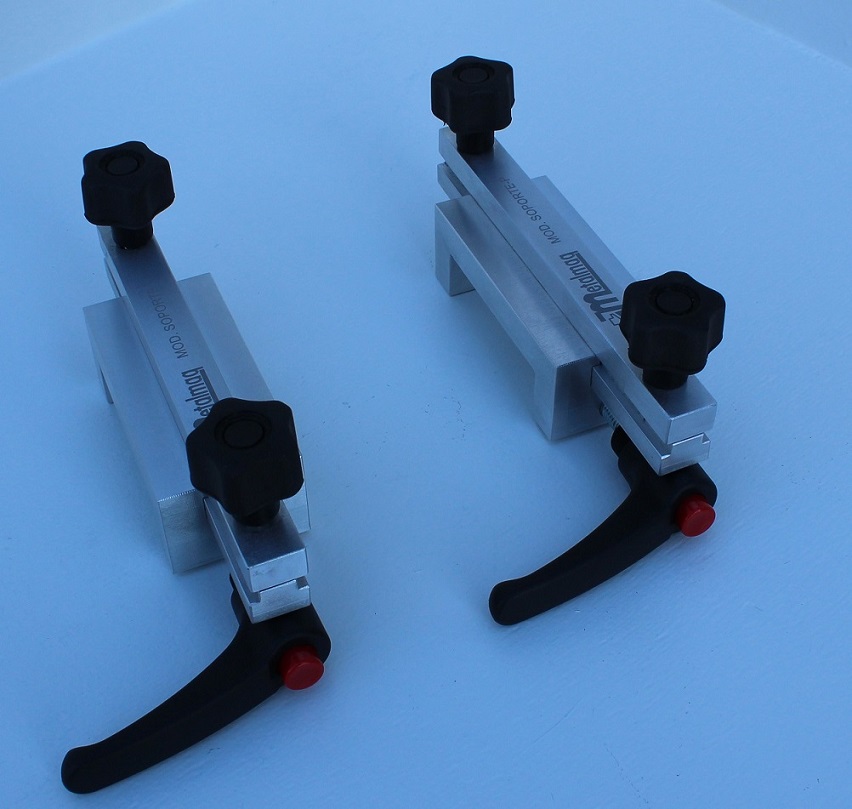

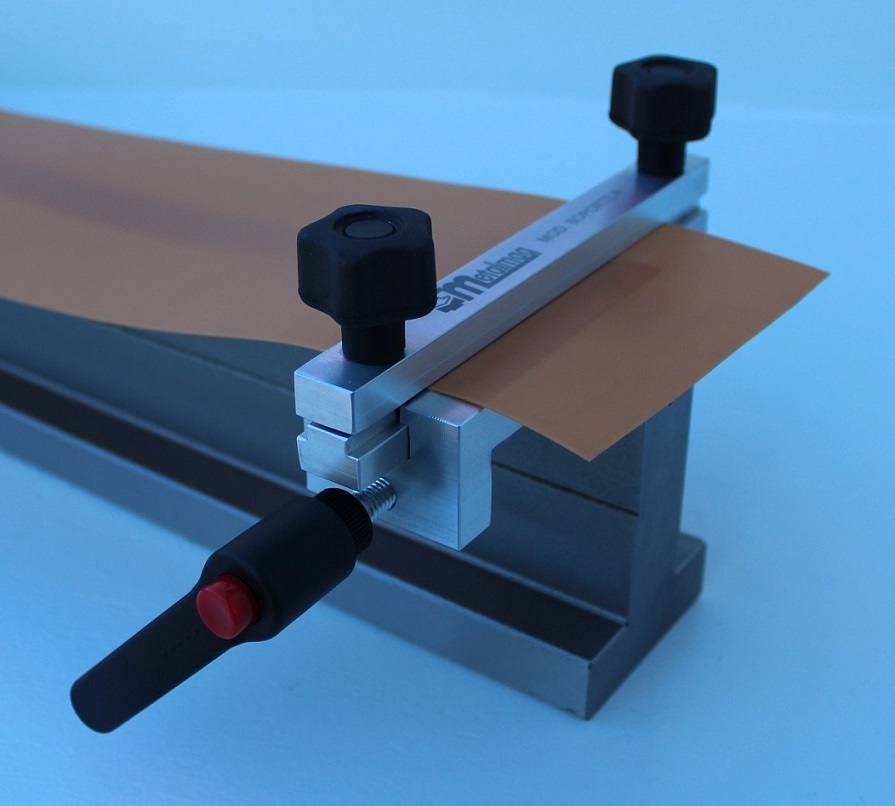

SUPPORT-P/60

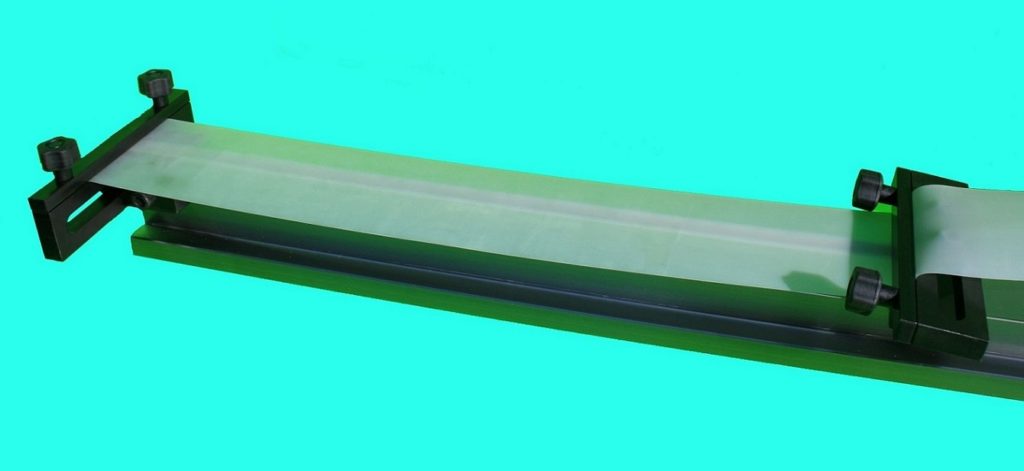

Support-P to fix the Protective Film

Support-P to fix the Protective Film in the die

Support-P installed in a Promecam die of press brake

Unique in the market!!, it fits the die and the Protective Film without using any type of key. For dies up to a maximum of 60 m/m width.

In the following video you can see the two types of supports ;

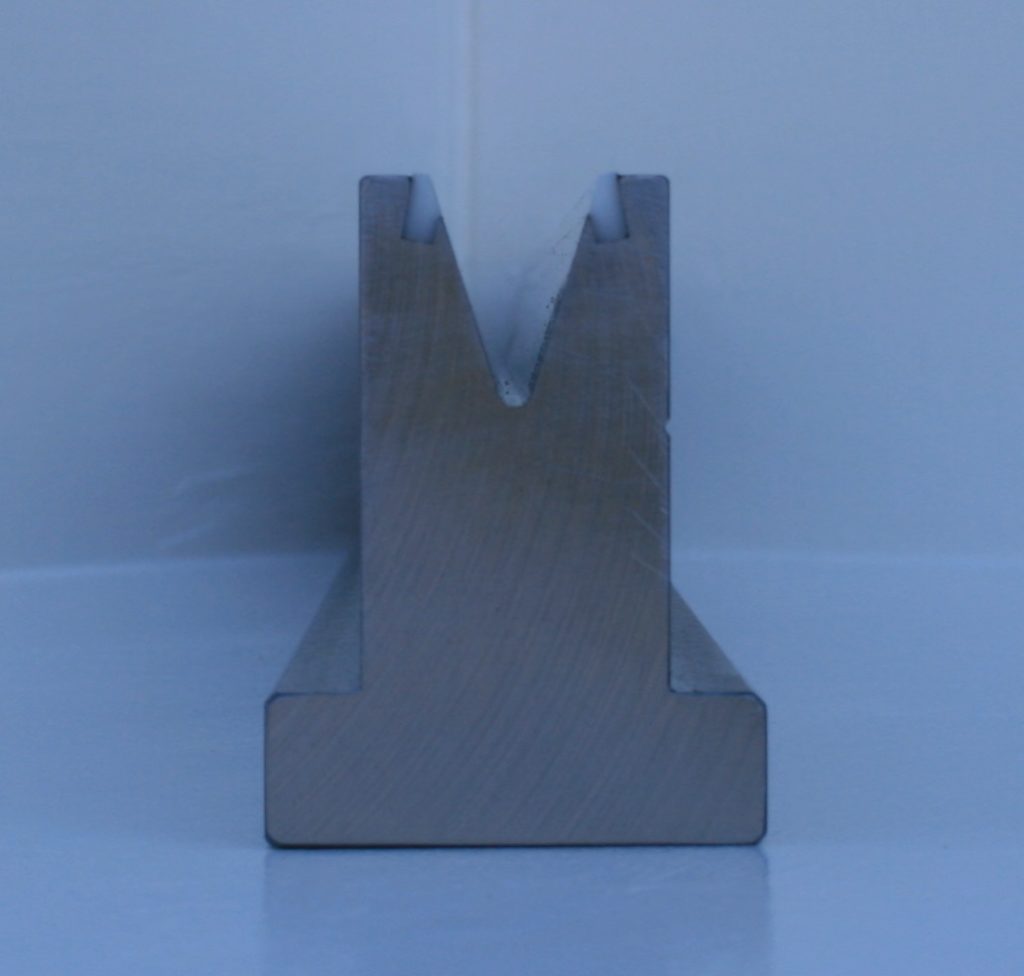

2.- SOLUTION: Dies with Polyamide insert

Die mod. 20.36/35º with Polyamide insert

Die mod. 20.36/35º with Polyamide insert, to avoid marks

Die mod. 20.36/35º with Polyamide insert, to avoid marks

These dies already come with a Polyamide insert in the upper part of the die, where the sheet will contact and therefore when bending it will not be marked at all. These matrices are manufactured standard for the Promecam system and are very competitive in price, they are already manufactured in large series.

The following video shows a practical demonstration of the “free marks” bend with the dies with Polyamide insert. ;

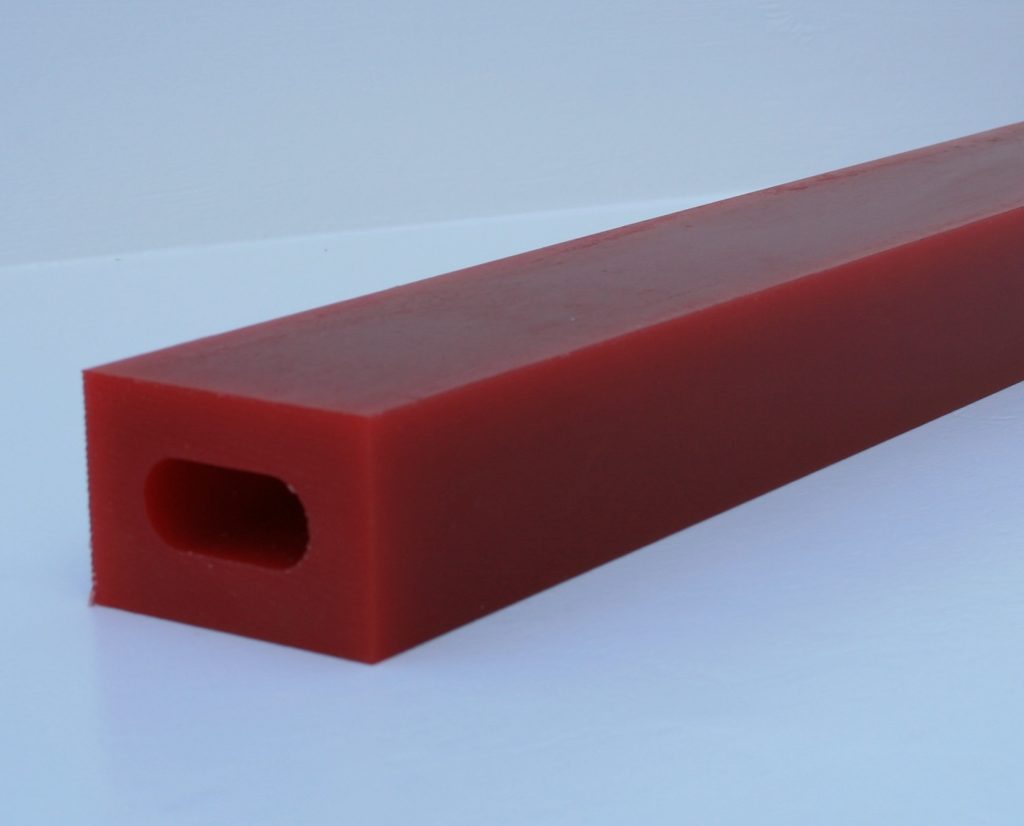

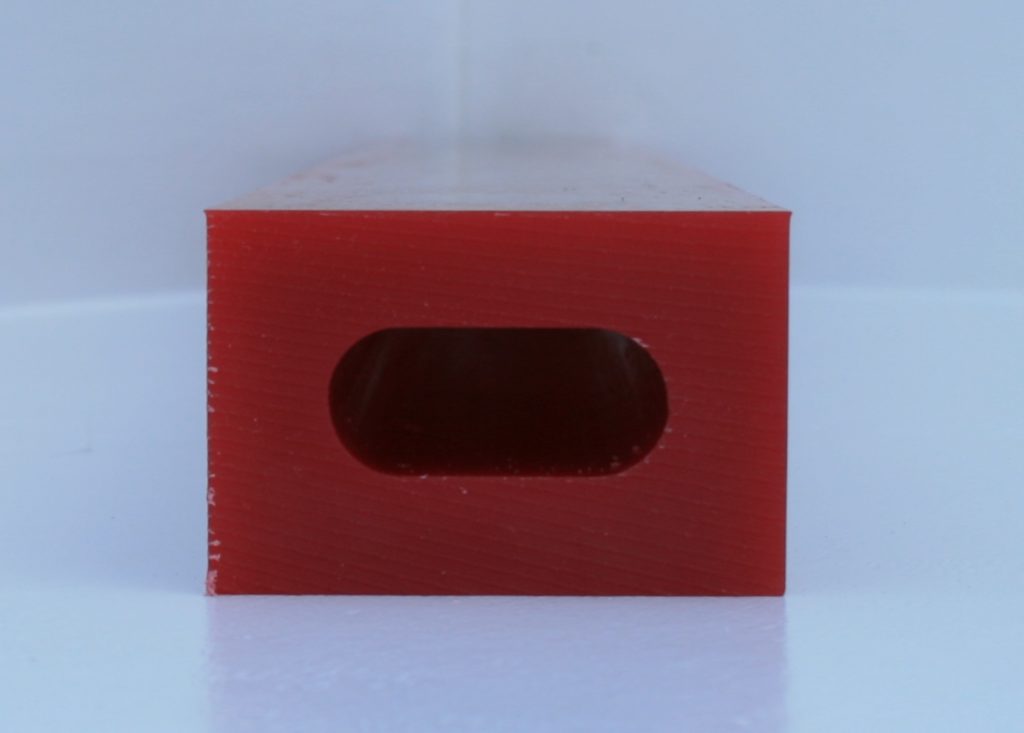

3.- SOLUTION: Bend with Adiprene Block

Adiprene Bolock mod. 62.4

with central hole

Adiprene Bolock mod. 62.4

with hole, to avoid marks

The last solution is to bend using the Adiprene Block, this system is especially recommended when bending big radii and you want to avoid marks.

As you can see in the video below the Adiprene Block adapts perfectly to the radius and does not cause any type of mark or scratch on the sheet:

Good day

Is this product available in New Zealand and if so. can I please have the details of the supplier.

Thank you

Wyane

Good morning, we ship worldwide!

Do you have these products in India? please give contact address and phone number.

Regards

Sanjiv

We sell all products all over the world.

You can contact info@metalmaq.es

I want buy a roll of tape width 5 inches 1m/m. kindly share supply price.

You can see the price in this link; https://metalmaq.shop/en/home/27-goma-polyurethane-08-mm-white-color.html#/4-size-30_m