METALMAQ and its exclusive after-sales service once again “surprise” its customers with the ingenious solution applied to a standard punch.

OUR AFTER-SALE SERVICE

Our after-sales service was born with the idea of helping and providing effective solutions to our clients in the sector of bending tools and thus being able to provide a fast and complete service in all these jobs:

– Cuts and facing in all types of metal sheet bending tools

– Milling and machining on punches and press brake dies

– Grinding of press brake punches and dies

All this is possible thanks to the machinery park that we have in our facilities in Gavà (Barcelona-SPAIN); saws, side grinders, wire EDM machine, milling machines, large grinding machines, drills, laser marking machine, etc.

A PRACTICAL CASE

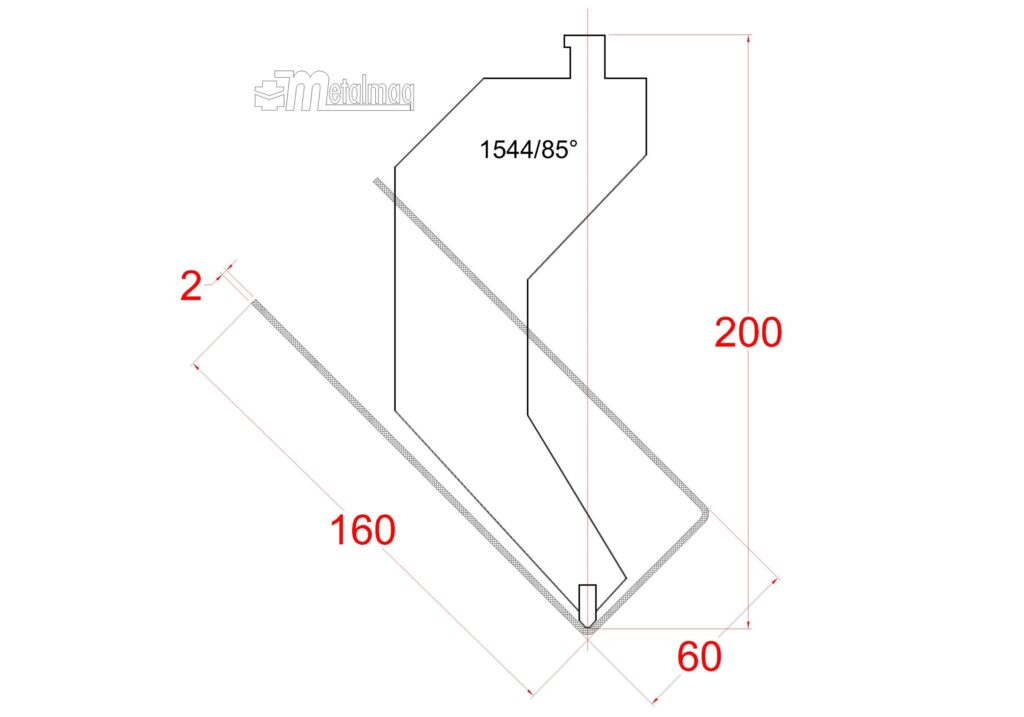

This same month, a customer with an AJIAL press brake of 170 Tons and 3 meters in length sent us a drawing of the part to be manufactured. The piece was a “U” made of 2 m/m iron sheet, with wings of 160 m/m, base of 60 m/m and a length of 150 m/m ….. once the piece had been studied, it was decided to modify a standard punch (which is on STOCK) and make a “window” so that the piece enters it and thus can be bent without collisions.

In the following plane you can see how the piece enters the punch. This same drawing was sent to the customer to check if his AJIAL press brake had enough stroke to be able to install this standard punch (mod. 1544/85º) with a height of 200 m/m.

AFTER-SALE SERVICE IN PROGRESS

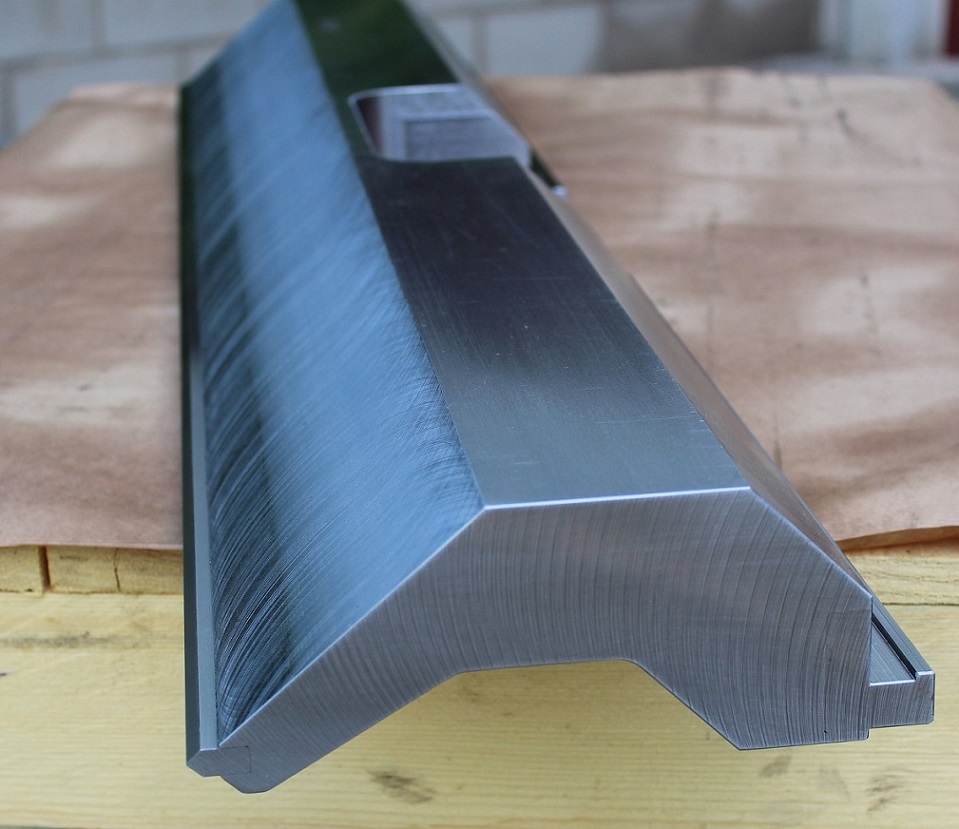

When the client verified that the proposed punch was adapted to his AJIAL press brake, our After-Sales Service began to machine the punch mod. 1544/85º, as can be seen in the following photos.

Side view of the milling in the punch mod. 1544/85º

Front view of the milling in the punch mod. 1544/85º

THE RESULT

The result (as you can see in the following photos) is a punch mod. 1544/85º modified with a window in its central part to be able to bend a 160 m/m wing “U”, with a 60 m/m base, 2 m/m thick in iron and a piece with length of 150 m/m.

Front view of the window in the punch mod. 1544/85º

Side view of the punch mod. 1544/85º

With an unbeatable price (since it is a standardized punch type AJIAL that is manufactured in series and has a very competitive price) we provide an economical solution with a delivery time of 1 week from the client’s approval of the modification plan.