¿WHAT IS POLYCARBONATE?

Polycarbonate is from the group of thermoplastics and among its many properties is the ease of working, molding and thermoforming. It is practically unbreakable and can be bent cold in various thicknesses.

There are also specific qualities for outdoor use: anti-vandalism, anti-abrasion, anti-reflective and suitable for food use, among others. In addition to multiple colors and textures: polished, engraved, glossy, matte, etc.

Polycarbonate plates are commonly used in the manufacture of skylights, wall cladding, facades, roofs, greenhouses, partitions, promotional or advertising signs, exterior or interior lighting, nautical, industry, signage, machinery protection, glazing and anti-safety. vandalism, glass lamination, shields, police shields, protective visors and a long etc.

CAN YOU BEND POLYCARBONATE?

The answer of whether it is possible to bend Polycarbonate is affirmative, but we must take into account two things if we want to bend it in a conventional metal sheet press brake and with the appropriate tools.

ELECTION OF THE APPROPRIATE PUNCH

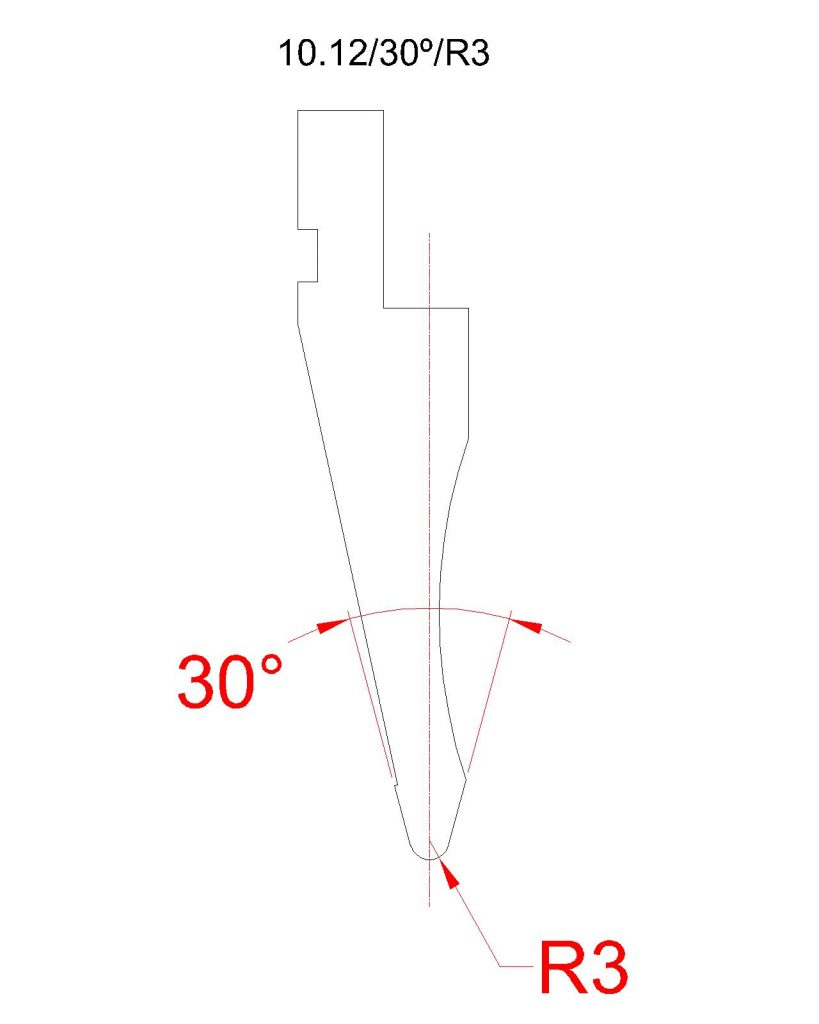

In choosing the punch we will base on two points. The first one is a punch with a closed angle since, as we will see later, the Polycarbonate needs to be bent to less degrees so that when it recovers it is left in the desired position. And secondly, the punch must have a large radius at the tip, at least 3 m / m, since Polycarbonate is a brittle material and if we bend it with a small radius we run the risk of being very marked or cracked.

Next, as an example, we show a punch (from the Promecam-European system) that can be ideal for bending Polycarbonate and as we can see it has a 30º angle and a radius of 3 m/m.

CHOOSING THE RIGHT DIE

In choosing the die we must take into account two things. The first is the choice of the V of the die, that is, the opening that it must have. From our experience we will use the same technique as in choosing a V for normal metal sheet, that is, we will focus on the Bending Table (see section) and thus calculate the die to choose. For example, if we have to bend a Polycarbonate of 5 m/m, we will follow the previous table and this tells us that we must choose a V of 40 m/m wide.

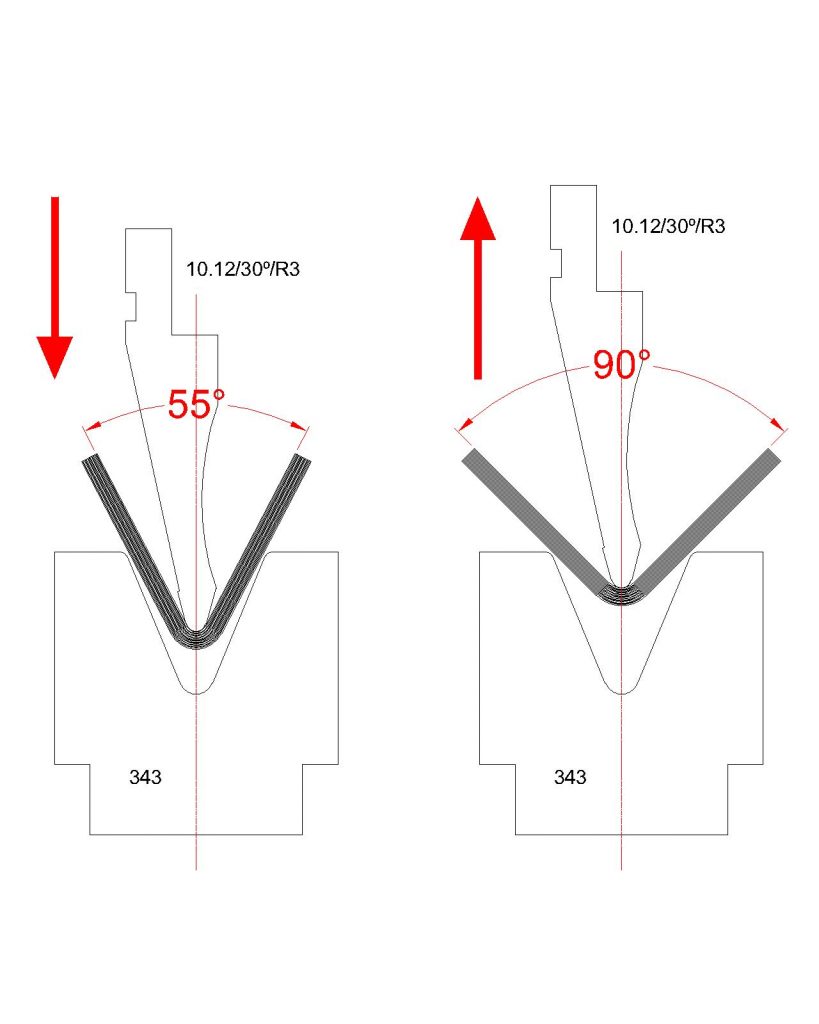

The second thing to keep in mind is that the die to bend polycarbonate must be at much less degrees than the fold we want to make, for example; if we want to bend Polycarbonate from 5 m/m to 90º, our best choice would be a V of 40 m/m at 45º, since Polycarbonate when bended has a very large return. In the previous case we must bend it to about 55º so that later, when we go back, we are left at 90º, that is, about 35º return !!, see attached sketch.

A VIDEO AS A BEST EXAMPLE

In the following video we will see how a 5 m/m polycarbonate is bended with a punch mod. 10.12/35º/R3 and with a radius of 3 m/m, the radius at 3 m/m will serve us so that the Polycarbonate does not crack or mark. We also see that it bends with the die mod. 343, which has a V of 40 m/m (it is the appropriate V as indicated by the Bending Tables) and is at 45º, this last point is important to be able to bend at less degrees and control the return of the material, which in the case of Polycarbonate is very important. As can be seen in the video, it bends at about 55º, so that once the polycarbonate returns it is at the desired 90º. Here it is clearly seen that the return of the Polycarbonate in the bending operation has been of 35º.

Do you sell in the USA?

We are looking for a machine to bend up to 10mm thick. Do you offer this? Pricing? Thanks

Good morning, we sell through our ONLINE SHOP to the whole world.

As you will see, we are manufacturers of bending tools and NOT machines.

can you please share the details for, how to bend 6 mm poly carbonate sheet,

without any impression on the inner radius.

The best thing is to do real tests, but it will always leave us with a large radius (internal of at least R8)