MAKING A LASER TO DRAW A HELP LINE FOR BENDING ON THE METAL SHEET?

Due to the concerns of our clients and their suggestions, we decided to carry out a study to see if it would be practical to make a module that would draw a visible laser line on the metal sheet and thus be able to align the parts that are complicated to make a stop in the current systems of the press brakes.

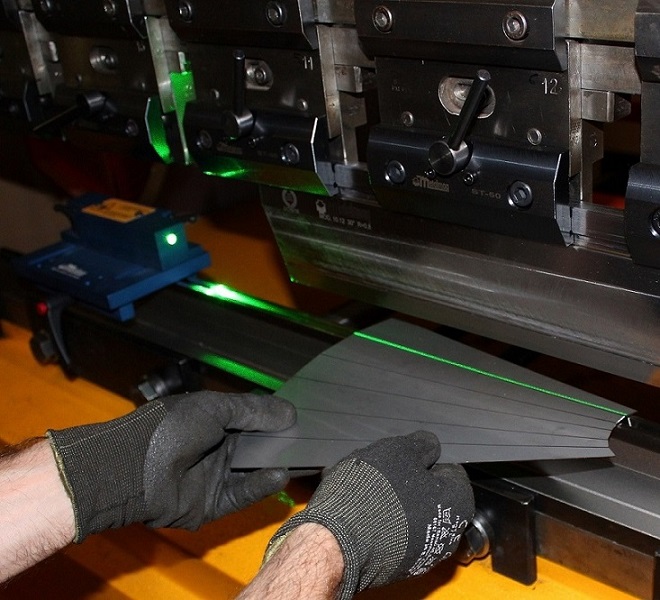

We have many customers that make with laser cutting the line where the metal sheet should be bended. But the drawback comes when they have to match this line with the tip of the punch, which is always carried out by eye, a complicated operation that does not offer sufficient guarantees of bending quality.

A DEEP WORK OF R&D

What if we help our customers to guarantee this reliability of aligning the punch with the bending line?

The challenge was great, but our R&D had to create a system to align the pieces that have to be bent, especially with geometries that are difficult to work with the traditional back gauge. And of course it had to be useful for most folders, be very reliable and at a very competitive price. The task was not easy, but the challenge was very tempting.

After several prototypes, in the end we outlined a very suitable solution for our market, after making a pre-series and leaving it for several months to a few clients, we saw that the result was very good. So we got down to work and began serial production.

THE PRODUCTION

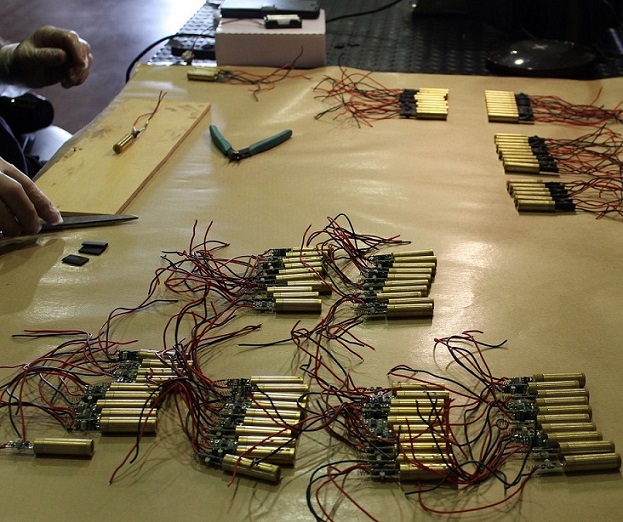

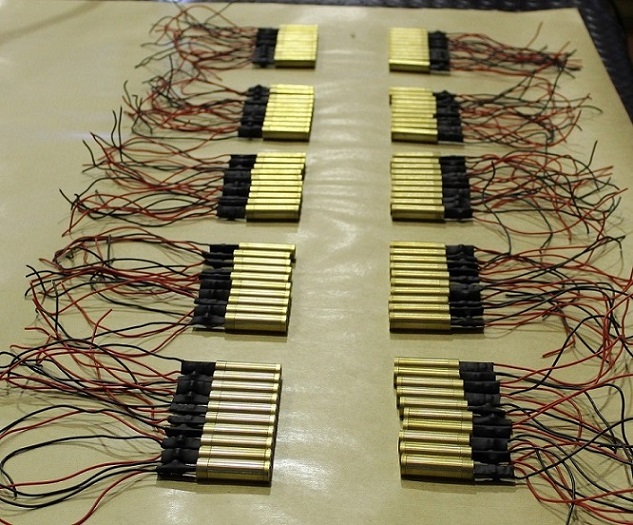

The soul of DIE´S LASER LINE 60/90 is its laser, so we started by assembling the first series of 100 units. A time consuming task with mounting of the housing, plate installation, wiring, testing, etc.

In the following pictures you can see various phases of its assembly.

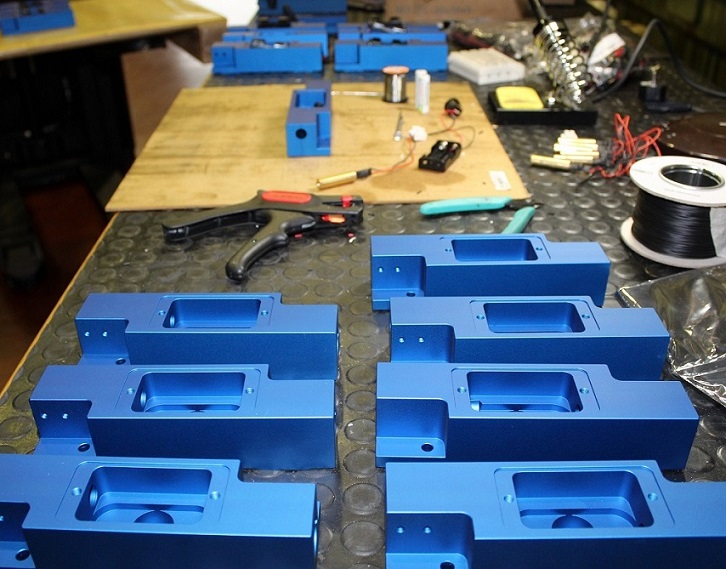

Once the lasers are assembled, we must mount their outer “housing”, wire the system and carry out the pertinent tests.

In the following pictures we can see the different phases of the assembly of the DIE´S LASER LINE 60/90.

WHAT MAKES THE DIE´S LASER LINE A UNIQUE IN THE WORLD FOR A TRACING SYSTEM FOR PRESS BRAKE?

We are going to describe the main characteristics that make the DIE’S LASER LINE 60/90 a unique system for aligning the pieces in the bending operation:

1.- VERY POWERFUL LASER MODULE

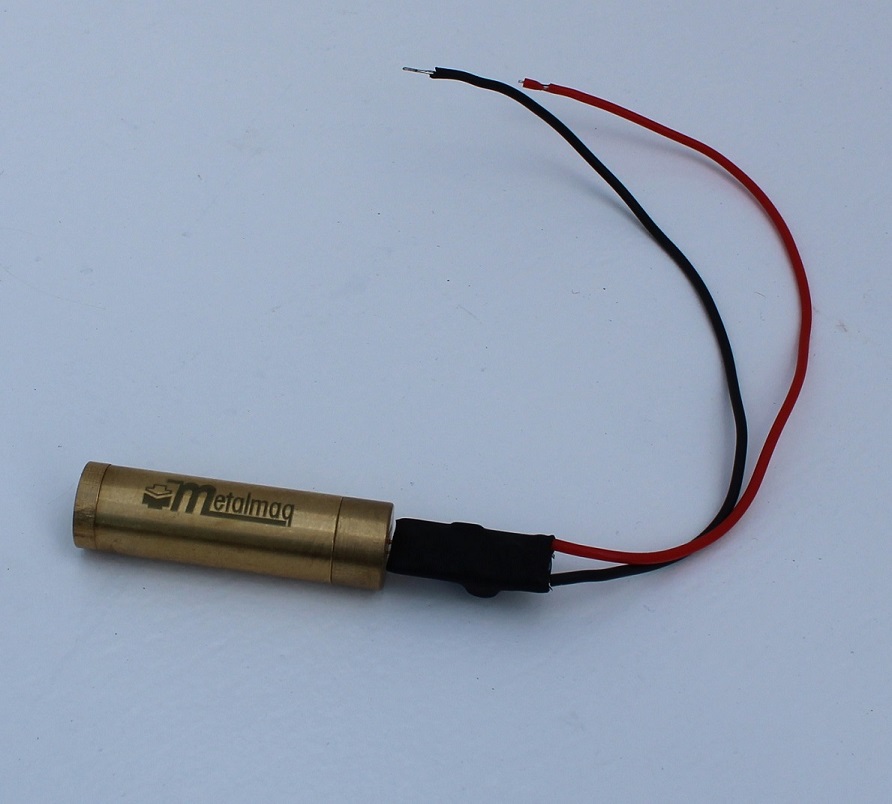

We assemble a very good laser module, which complies with the UNE EN 60825-1 / A2 STANDARD and which has the following characteristics;

Operating Voltage 2,4 to 3,7v

Line length of more than 6 meters (with little outside light).

Operating current <280 mA

Output power 10mW

Wavelength 532nm

Lifespan> 4000 hours under proper use

Working temperature from 10 to 35º

2.- THE LASER MODULE IS SOLD SEPARATELY

The laser module has a lifespan of more than 4.000 hours, with proper use. That is why the laser module can also be purchased independently.

3.- EASY INSTALLATION

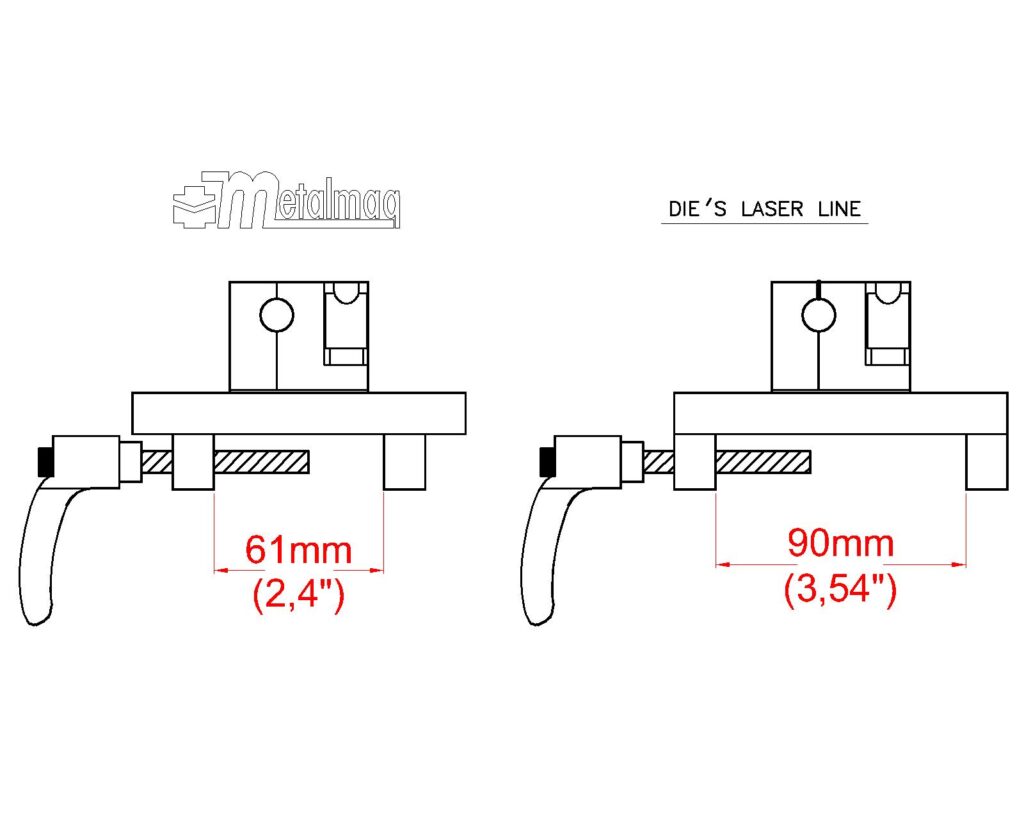

With a simple handle, the DIE’S LASER LINE 60/90 is coupled to dies of 60 m/m and with a small change of screws it adapts to dies of up to 90 m/m wide. As can be seen in the following sketch:

4.- QUICK ADJUSTMENT TO CENTER THE LASER BEAM

Thanks to its two small handles, adjusting the laser beam to the center of the die is super fast and very practical.

5.- REVERSIBLE

Only by changing the fixing handle to the die sideways, the DIE’S LASER LINE 60/90 is reversible and can be left-hand or right-hand.

6.- SUPPLIED WITH BATTERIES INCLUDED

The DIE’S LASER LINE 60/90 is supplied with 2 AA 1.5v alkaline batteries. Its duration is about 8 hours of continuous work. Our recommendation is that for intensive use rechargeable batteries are used (our environment will appreciate it).

7.- DESIGN

With a very careful design, the DIE´S LASER LINE 60/90 has been manufactured in high resistance aluminum, we have given it a sandblasted finish and it has been anodized in matt blue. The result is a practical tool with a very visual finish.

8.- ITS LOW PRICE

Its price has no competition and there is no laser line for press brakes on the market that gives so much for so little.

PRACTICAL DEMONSTRATION OF DIE’S LASER LINE

To see its operation and especially its use, you can view the following VIDEO, where there are also three practical demonstrations with three types of very common partst and with difficulties to use with the back gauge of the press brake.

WHERE TO BUY THE DIE´S LASER LINE 60/90?

If you have read this article and you sometimes find it difficult to use the back gauges on your press brake, I do not think you have any doubt about the advantages of incorporating the DIE’S LASER LINE 60/90 in your production, to speed up and start saving time in sheet metal folding.

Another great advantage? its ease of purchase in our Online Shop, you will receive it in your workshop without any effort.

6 ft Press Brake- what is everything I need?

This model is our best option;https://metalmaq.shop/en/home/453-dies-laser-line-plus-30mw-for-press-brake.html

I need for 3100mm laser line tracker.

Do you have some for me?

The most powerful are the i-LASER LINE (https://metalmaq.shop/es/home/449-2151-i-laser-line-30mw-para-plegadora.html#/194-transformador-enchufe_europeo_220v) and the DIE ´S LASER LINE PLUS (https://metalmaq.shop/es/home/453-2156-dies-laser-line-plus-30mw-para-plegadora.html#/194-transformador-enchufe_europeo_220v).

The two models make a very powerful laser line of up to 6 meters

I have a 60′ press brake that needs a laser.

For this length it is better to put two units (one in front of the other) of the DIE’S LASER LINE PLUS model; https://metalmaq.shop/en/home/453-2156-dies-laser-line-plus-30mw-for-press-brake.html#/194-transformer-european_plug_220v