METALMAQ manufactures a special punch and die for a “retrofitting” made by Hidrogarne in a used press brake.

THE COLABORATION

The collaboration with HIDROGARNE (manufacturer of Hydraulic Presses, folding machines, etc.) goes back a long way. On this occasion they contact us because they have to do a retrofitting to a second-hand press brake and their client has to make a “U” piece 110 m/m high and 35 m/m base, in INOX 1,5 m/m.

THE DESIGN OF THE PUNCH AND THE DIE

Due to the dimension of the part to be manufactured, the punch also has to be very large, but since the press brake has a limited stroke, a lower die than usual must be designed, so that the customer can work with the press brake with sufficient opening in order to extract the part.

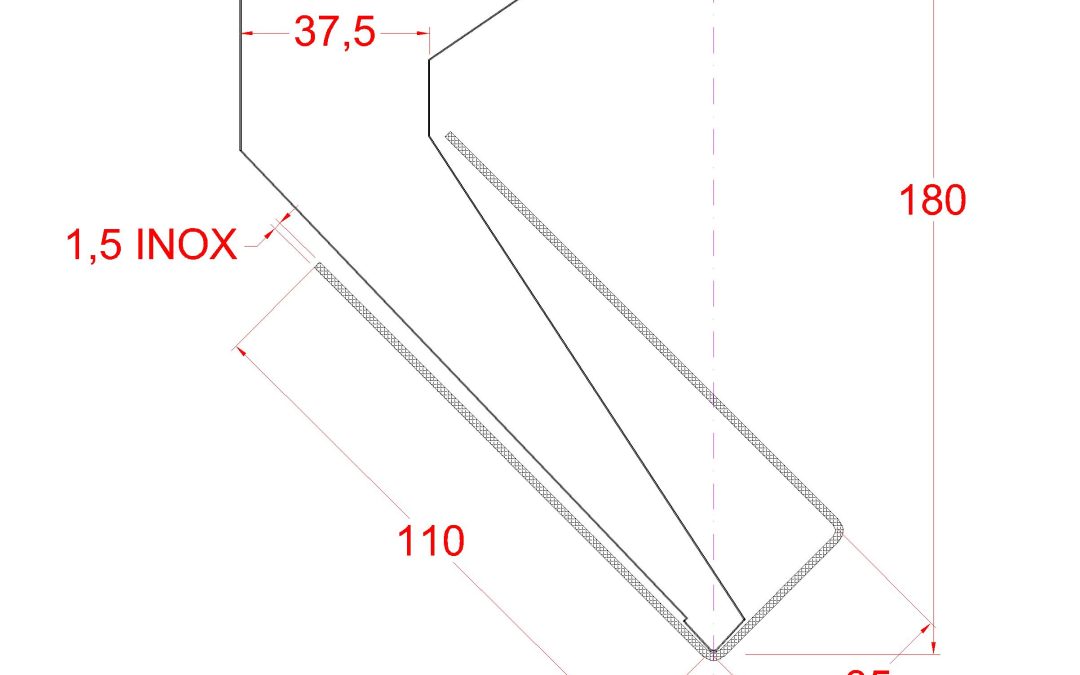

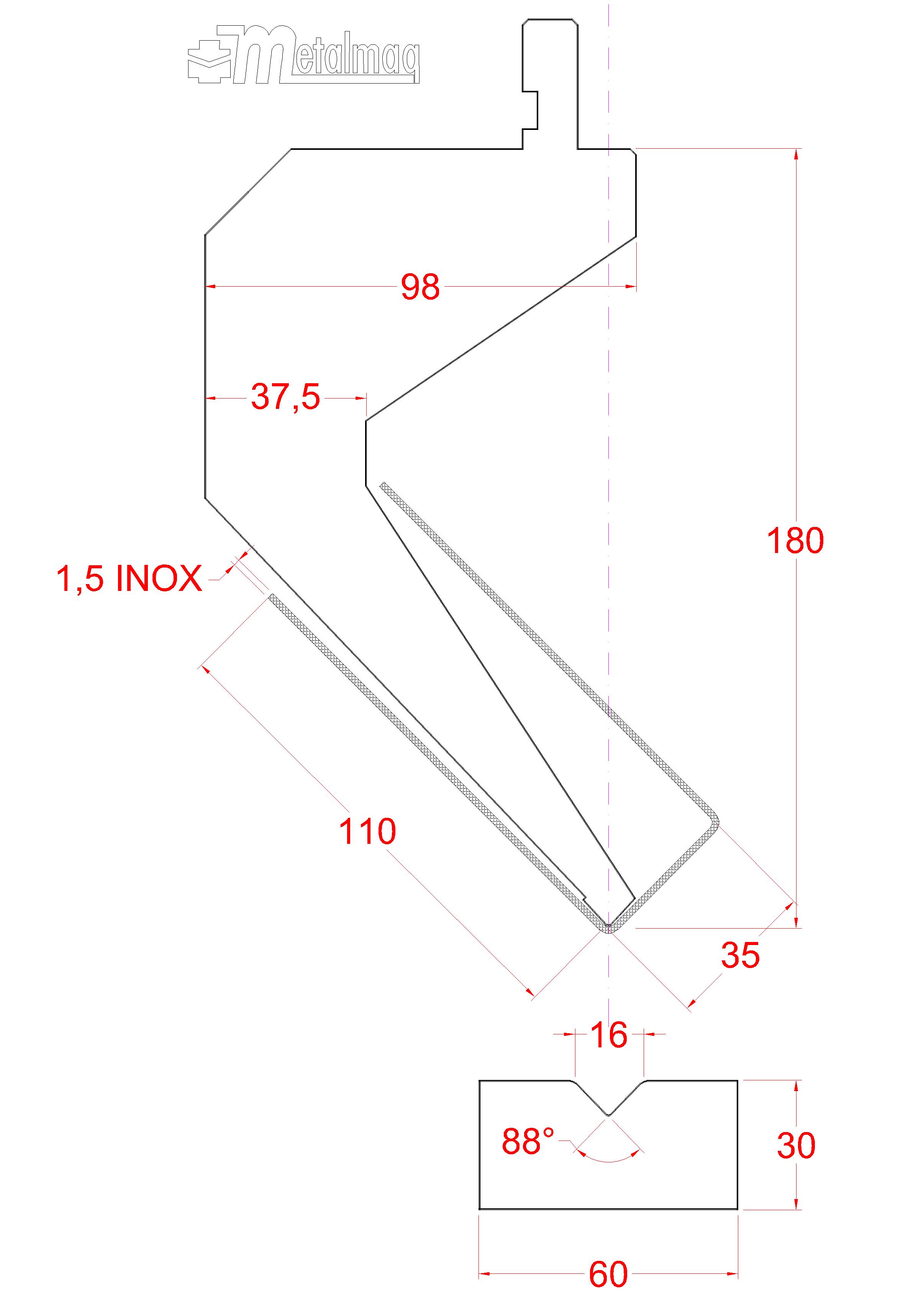

Below you can see the design that was proposed to our client;

Once the client accepts the design, we start production.

The punch has the following characteristics;

– Punch mooring type PROMECAM or also known as European mooring

– Total height of the punch of 180 m/m + mooring, so that you can bend the proposed piece without difficulty

– Punch manufactured in a total length of 1.200 m/m, but made in 4 sections of 300 m/m, to facilitate its installation, since being so large it is a very heavy punch

– Punch with an 88º angle to have a little margin for the elastic return of the metal sheet

The die has the following characteristics;

– Total height of the die of 30 m/m, to leave the maximum available stroke to be able to bend the piece without problems

– Die manufactured from a whole piece of 1.200 m/m

– Die with an 88º angle to have a little margin for the elastic return of the metal sheet

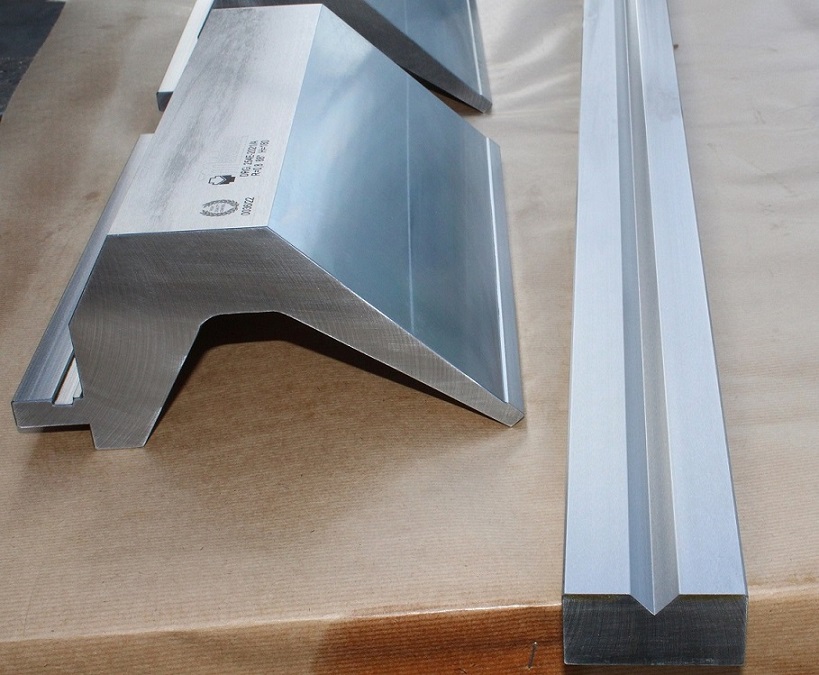

In the lower image you can see the details of the manufactured punch and die.

THE MANUFACTURING

The punch has been made of steel 42CrMo4 tempered in the work areas, to prevent premature wear and thus prolong their useful life, it was finally rectified. It has been decided to use this type of steel to ensure its resistance, since having this “padfood” its resistance may be compromised if it is made with a steel with other characteristics.

The die has been manufactured in C-50 steel, tempered by induction and rectified, since it does not require a too great resistance.

In the lower image you can see how both the punch and the die installed in the press brake have remained.