METALMAQ manufactures special punches of 7 meters length for a company located in the north of Spain, dedicated to the production of large metal structures with a large press brake of 630 Tons and 7 meters length.

THE CUSTOMER’S PROBLEM

Our customer wanted to replace some punches that he already had in his large 630-ton, 7-meter-long press brake, where he manufactures large metal structures with thicknesses of up to 50 m/m.

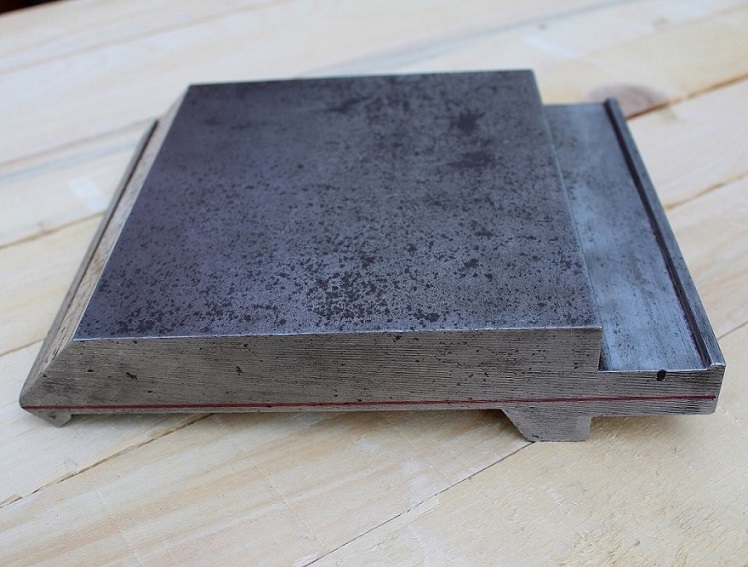

As the customer did not have plans of the punch, he decided to send us a section of the current punch that he uses in said metal sheet press brake. And on this section of the attached photograph we made the designs together with the necessary studies to manufacture them new and with all the guarantees of quality.

THE DESIGN OF PUNCHES

Due to the customer’s demands and the type of work to be carried out, the punch must have the following characteristics;

– Special upper mooring, just like the sample sent, so that the punches work properly to his press brake.

– Punch height of 238 m/m, since it must be the same as that sent in the sample.

– Length of 510 m/m, since the customer wants the punches to be practical to install on the press brake. Therefore we must manufacture 14 sections of 510 m/m, to reach more than 7 meters in length.

– 86º angle to have a little margin due to the elastic return of the metal sheet.

– Radius of 6 m/m at the tip, this is important so that the durability of the punch is long and not punished excessively when bending very thick metal sheet.

In the lower image you can see the details of the manufactured punches.

THE MANUFACTURE

The punches have been manufactured in 14 sections of 510 m/m, so that it has a total length of 7.140 m/m, that is to say, more than 7 meters !!

The punches have been manufactured in 42CrMo4 steel hardened in the work areas, to avoid premature wear and thus prolong the useful life of these and finally they were rectified. This steel is one of the best on the market and it has been necessary to use it to give the punch a lot of hardness, since it must resist a lot of pressure to bend up to 50 m/m thickness.

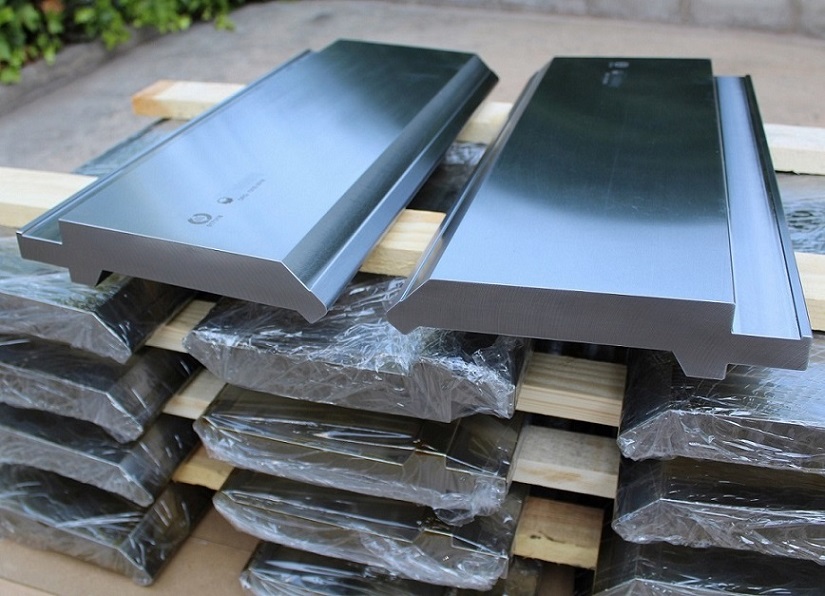

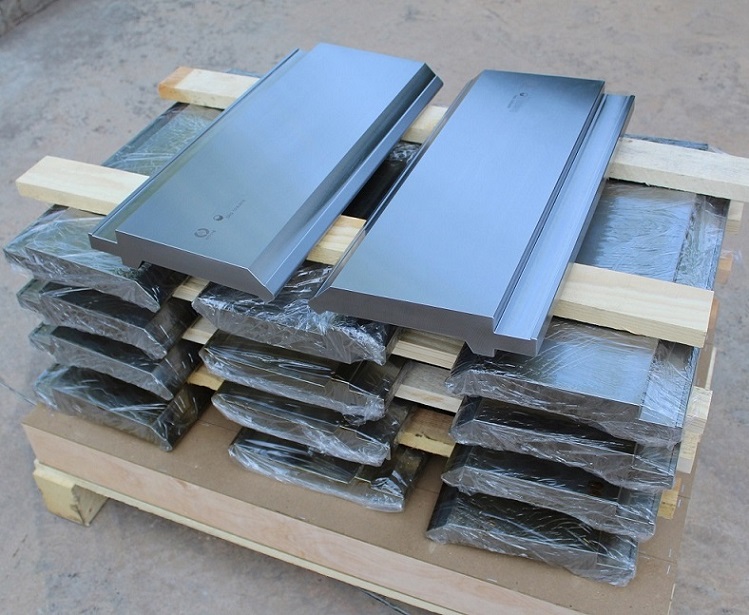

As can be seen in the images below, the punches were shipped perfectly packaged and on a well protected pallet.

Lot of 14 punches of 510 m/m length ready to be packed

Lot of 14 punches of 510 m/m very well packed and ready to be shipped

RESULT

The result is another satisfied customer and punches manufactured in 7 meters length ready to start producing metal parts of great thickness.

Every time more customers want punches, dies or special tailored tools for their specific applications and find METALMAQ as their ideal manufacturer.