METALMAQ manufactures punches for BYSTRONIC-BEYELER press brakes, specifically 16 metres of punches (in 1-metre sections), for a company in the south of France specialising in large-format metal constructions for industrial building facades, among other activities.

THE DESIGN OF THE PUNCHES

Bystronic-Beyeler RF-A Clamping

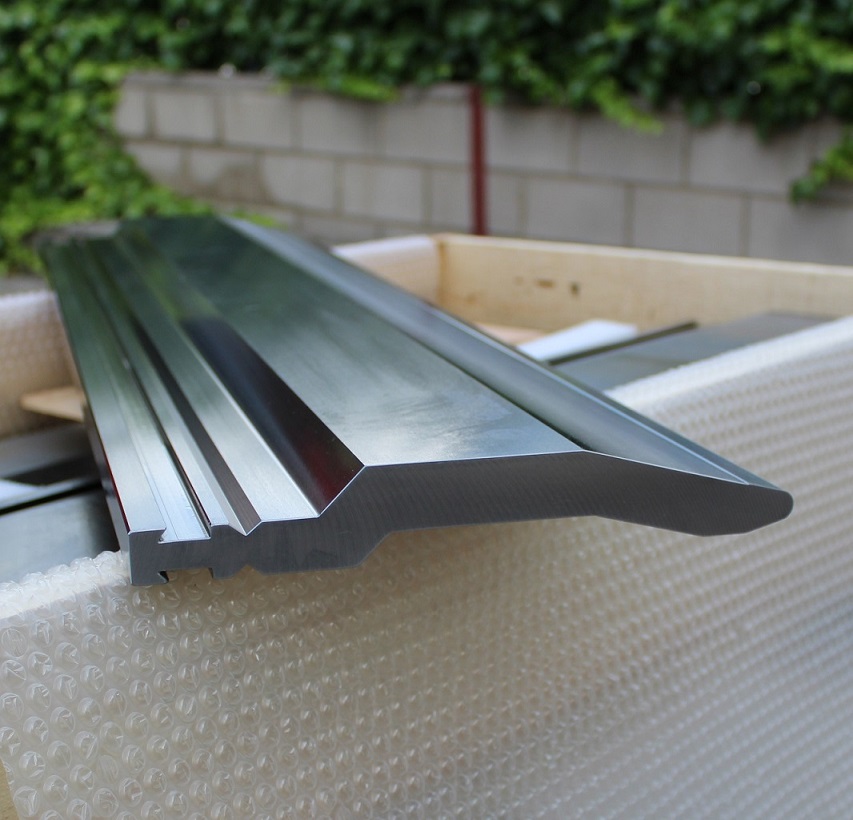

The customer has a 16-metre long Bystronic-Beyeler press brake with a typical Beyeler clamping system, the RF-A model. This type of clamping system has inclined slots where the punch clamp is housed, which means that when the clamps are closed (in this case hydraulically), they are very well secured and at the same time self-centring. This is a characteristic system of Bystronic-Beyeler press brakes and has always been very successful. It is their own “Wila” system, as they themselves say, which allows them to automate the loading and unloading of punches and to speed up their changeover in order to avoid wasting time on machine set-up.

Punch with somewhat of a recess

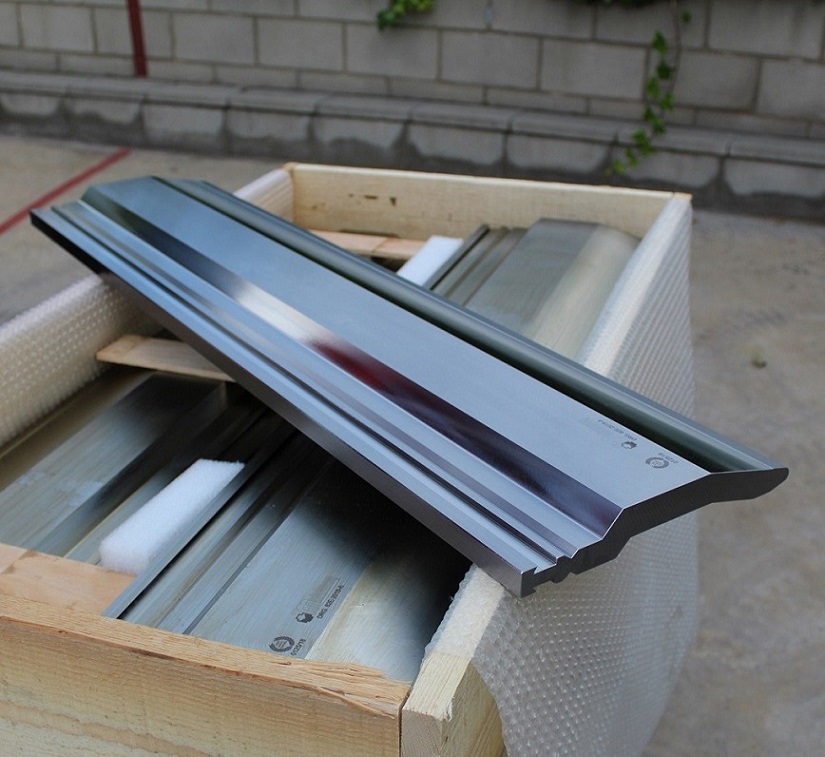

With this punch, the customer wanted to make certain parts and somewhat of a recess was designed in the central part of the punch to allow bending their designs and avoiding collisions, as can be seen in the first picture above.

6 m/m radius

Also due to the requirements of the part to be made, the punches were manufactured with a 6 m/m radius, as can be seen in the second picture above. Therefore, the bent part will have this 6 m/m radius in its interior.

30° angle

The angle of the punch is 30°, also due to the requirements of the parts to be manufactured, as some of them are very closed and it was essential to have this angle at the tip of the punch.

Punch height H=175 m/m

The manufactured punch height is 175 m/m in total, which is a very typical measurement for Bystronic-Beyeler punch models with RF-A clamping, and they were manufactured in this way due to the customer’s repeated experience with the other tools for their press brake of the same height.

MANUFACTURE

The punches are manufactured from hardened 42CrMo4 steel (with a hardness of about 60 HRC) in the working areas to prevent premature wear, thus prolonging their service life, and finally they are ground. This steel has a very good quality and is the one normally used in the sale of Trumpf, Bystronic, LVD tools, among other brands known worldwide.

The picture below shows the entire lot of 16 metres (in 1 metre lengths) of punches in the packaging process.