METALMAQ manufactures a special tool for bracket reinforcement for a regular customer in the province of Barcelona, to be installed in their AMADA press brakes with Promecam clamping (or European tooling system).

THE PROBLEM OF THE PART

Our customer had a large order for 2 m/m stainless steel sheet metal brackets, where high rigidity was required, but without increasing the thickness of the sheet metal.

These brackets had to withstand feeding equipment and ensure their rigidity throughout their service life.THE SOLUTION

Our Technical Office studied how to increase the torsional strength of the bracket without increasing the thickness of the sheet metal and decided to make a tool with two protrusions so that, when the sheet metal was bent, there would be two embossments. For METALMAQ, this was a system that we had already used before in very similar situations. Our great specialisation in the world of bending gives us the advantage of having experienced many different situations in this field.

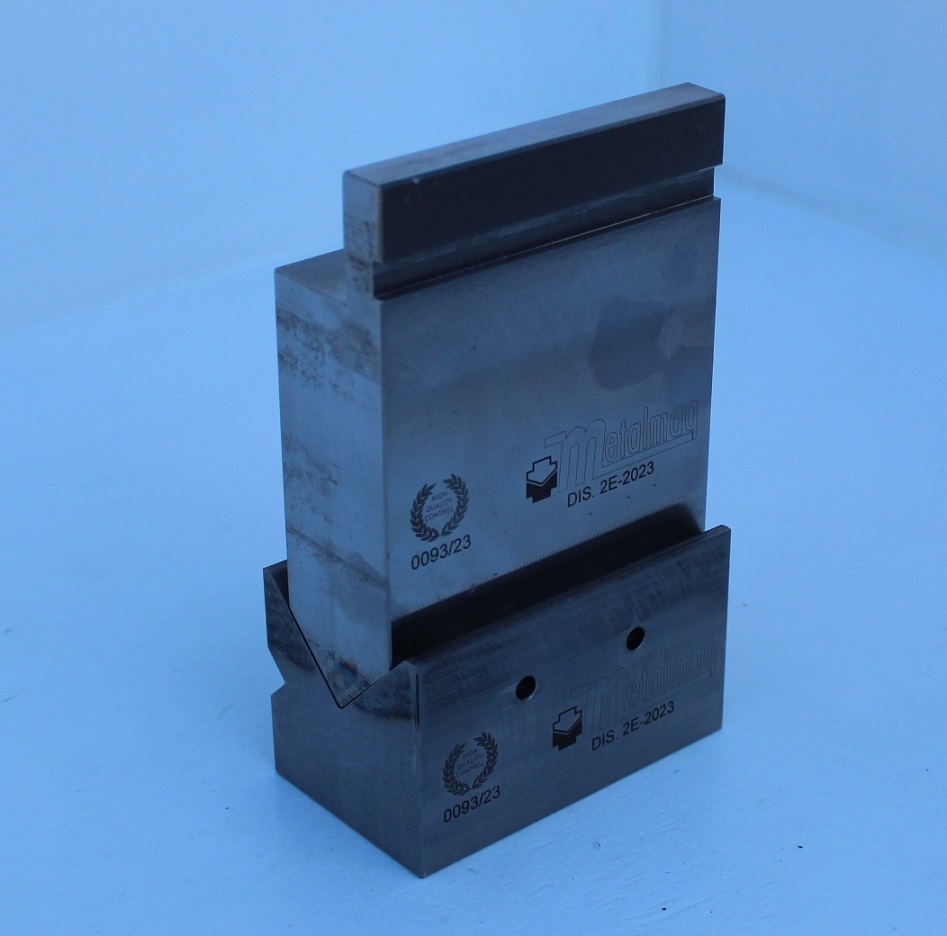

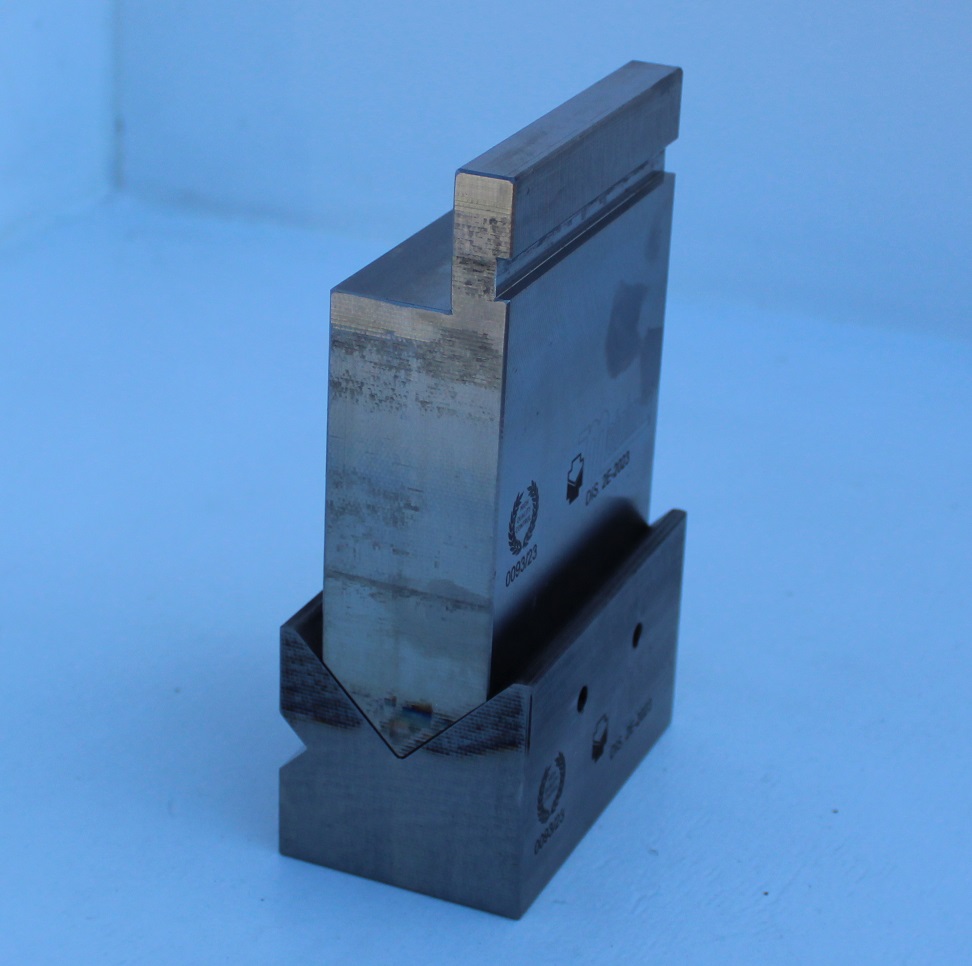

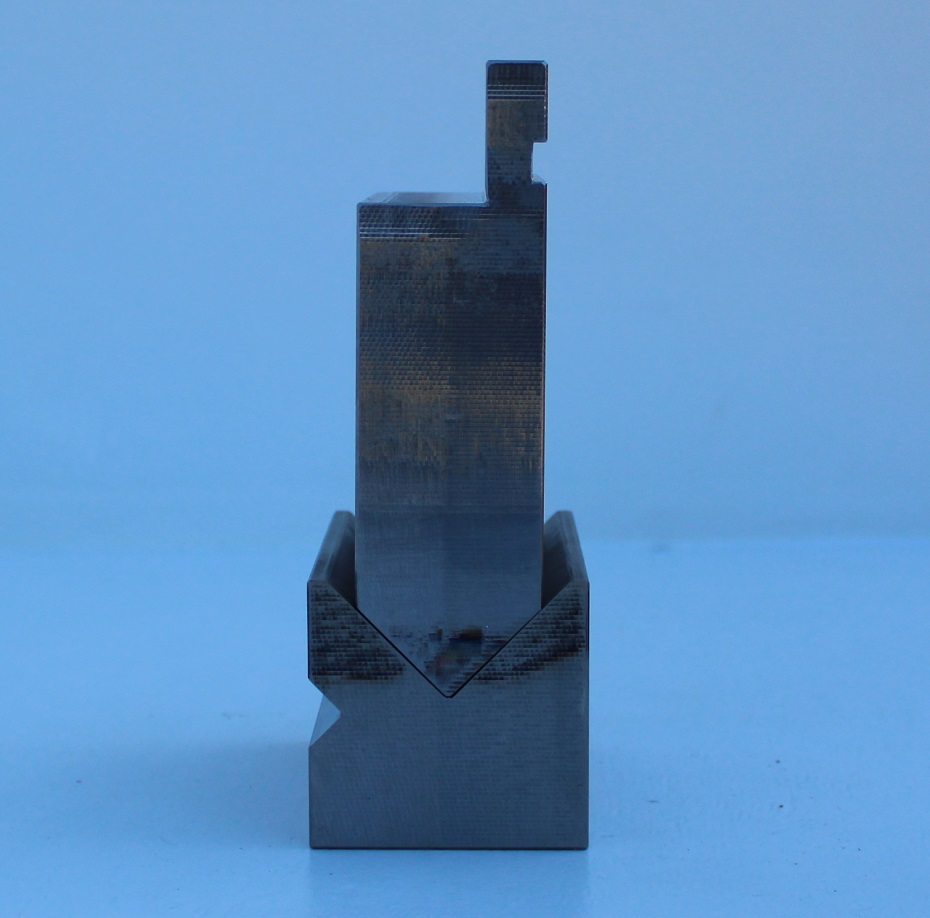

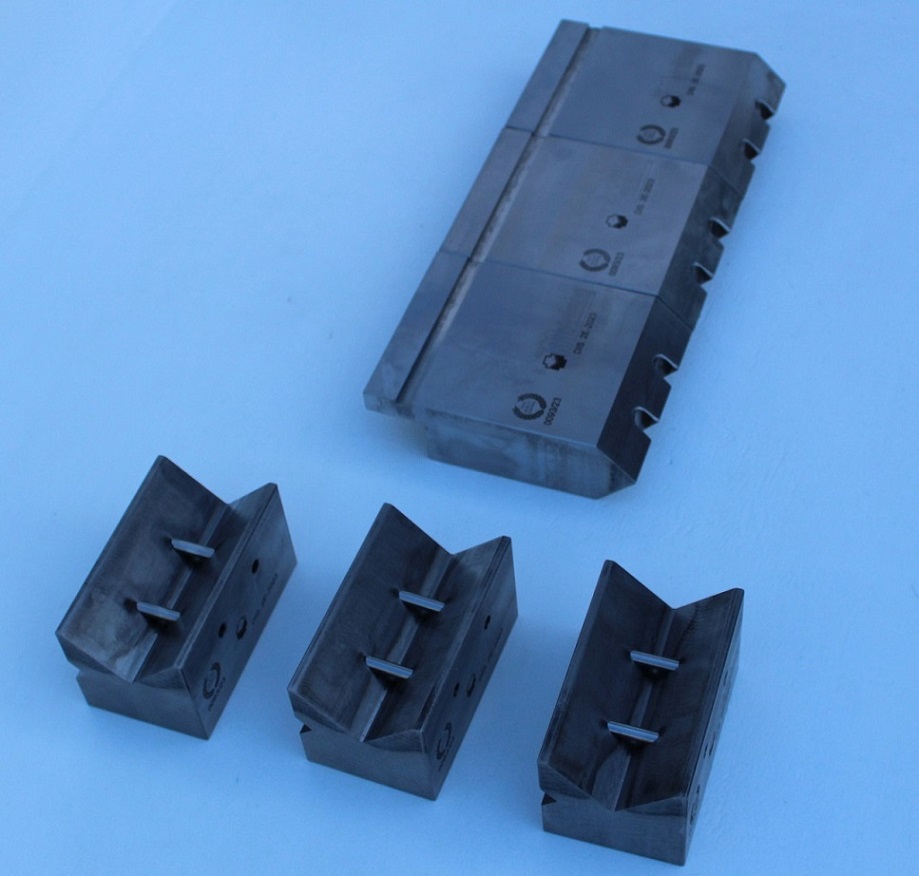

Above there are three views of one of the tools manufactured, consisting of a punch with Promecam-European clamping and a die also with Promecam-European clamping.

As can be seen in the photographs, all the tools manufactured by METALMAQ are marked with our logo, the tool reference and the work order. The latter allows us to provide traceability throughout the process and assure the customer that a replacement can always be manufactured with the transfer of this data, as we keep all the drawings and manufacturing parameters of special tools.

THE MANUFACTURING

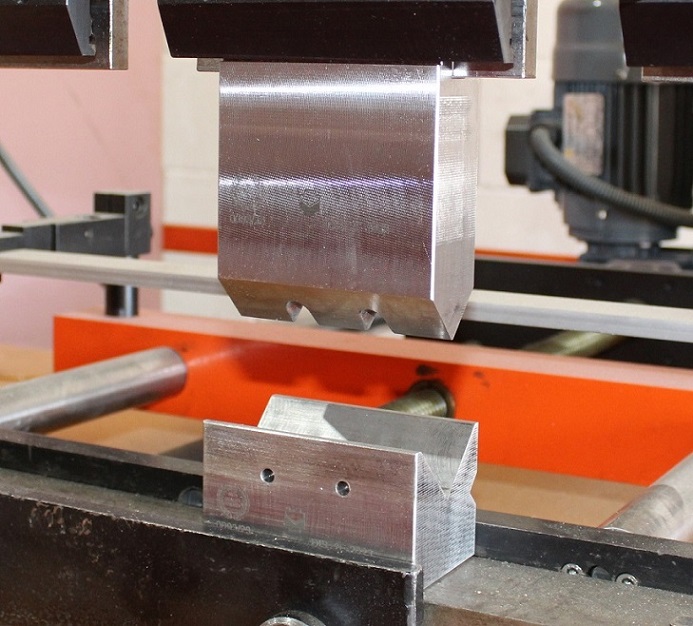

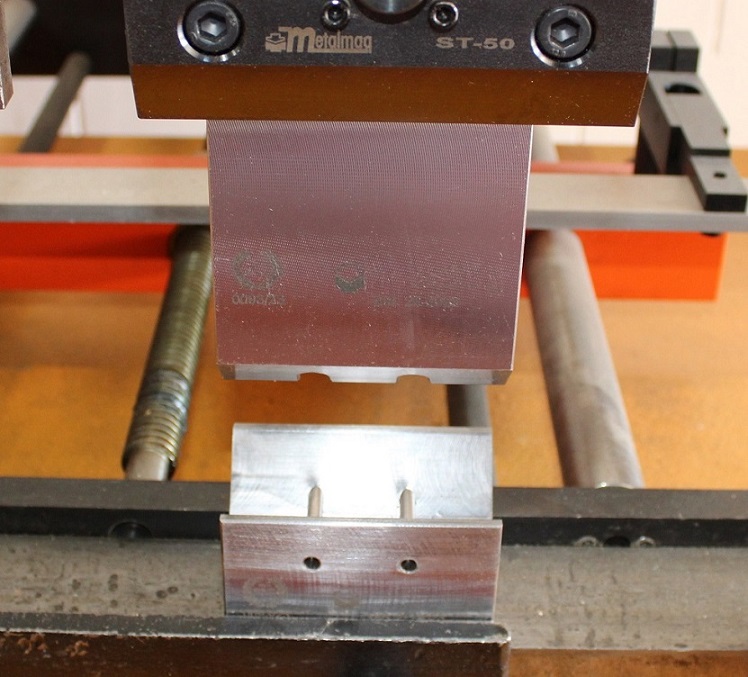

The following pictures show the tool in our MEBUSA press break in its testing and verification phase. This operation is always essential when we manufacture special press brake tools, so that our customer can start production as soon as he receives the tool.

In summary, we manufacture three tools with a length of 100 m/m each, to enable the bending of the reinforced brackets in three different press brakes, as can be seen in the following pictures:

The manufacturing has been carried out with our best materials, special 42CrMo4 steel, with the work areas being induction hardened (reaching hardnesses of 58 HRC) and ground.

RESULT

The pieces resulting from the tests were perfect, with very well defined embossing and thus ensuring the strength of the new bracket manufactured by our customer.

And the result, as it could not be otherwise, is another special tool manufactured by METALMAQ with an excellent result, as can be seen in the following video: