METALMAQ manufactures 6 meters of special punches with PROMECAM mooring for a well-known company located in Lleida (Spain) dedicated to the production of profiles for industrial buildings.

THE CUSTOMER PROBLEM

The customer is already a regular of our tools and, on this occasion, he tells us that he must make a piece in the shape of a “U”, with 150 m/m in both wings, a base of 75 m/m and in metal sheet of 1 m/m. He asks us for advice because he does not have any punch in his press brake to be able to do this work and the project he has in hand is considerable and very interesting.

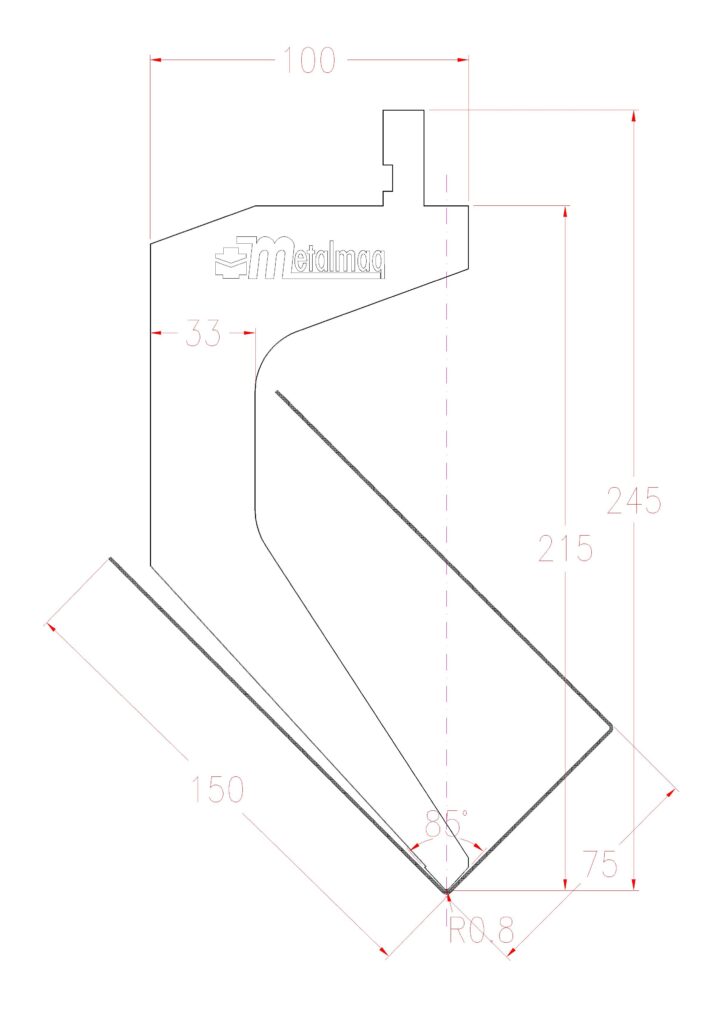

We designed a punch with PROMECAM mooring (or European system), since its 6 meter AXIAL press brake is prepared for this system of tools. As can be seen in the upper sketch, the punch is quite high, 215 m/m + mooring. Once we check with the customer that the press brake has enough opening to accommodate them, we pass the design of the punches to the customer for verification and approval.

THE DESIGN OF THE PUNCHES

When the customer accepts the design, we start with the production. The punches must have the following characteristics;

– Superior mooring with PROMECAM mooring (or European system), since its 6 meter AXIAL press brake is thus configured

– Total height of the punch of 215 m/m + mooring, with a total width of 100 m/m

– 7 sections of 835 m/m, plus a section of 415 m/m to achieve the desired total length of 6.260 m/m

– Angle of 85º to have a little margin for the elastic return of the sheet

– Radius 0,8 m/m at the tip, since the punch is designed for thin metal sheet and you do not want the piece to be excessively rounded.

– The punch according to its design will have a resistance of maximum 50 Tons per meter, more than enough for what our client wants to do. But it is important to program this tonnage limit on the press brake in case this punch is used for other parts.

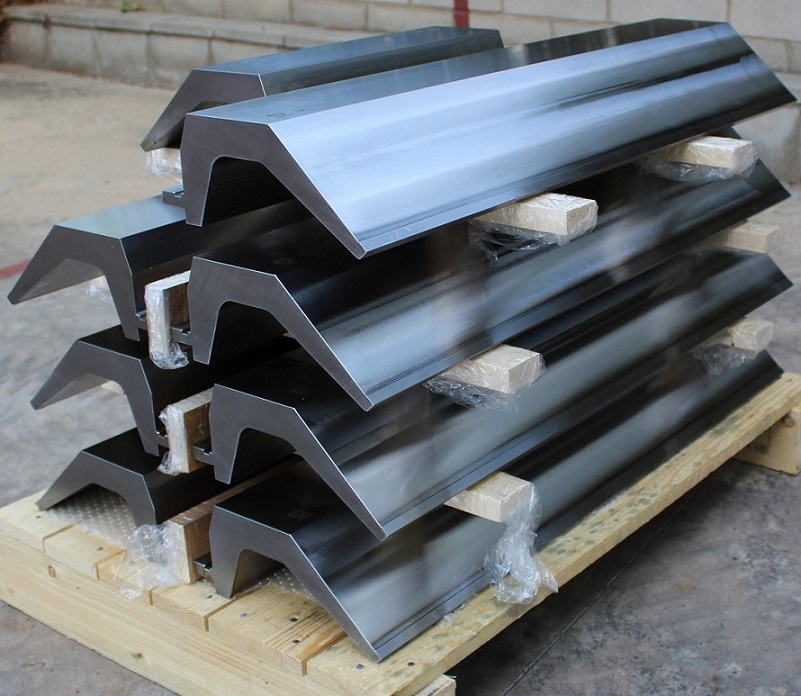

In the following photo you can see at the top a punch mod. 10.10/88º (it is one of the most sold standard punches) to have the comparison of the size of the special punches manufactured and thus be able to appreciate their large size.

THE MANUFACTURING

The punches have been manufactured in 42CrMo4 steel tempered (with an approximate hardness of 60 HRC) in the work areas, to avoid premature wear, prolonging the useful life of these and finally they have been rectified.

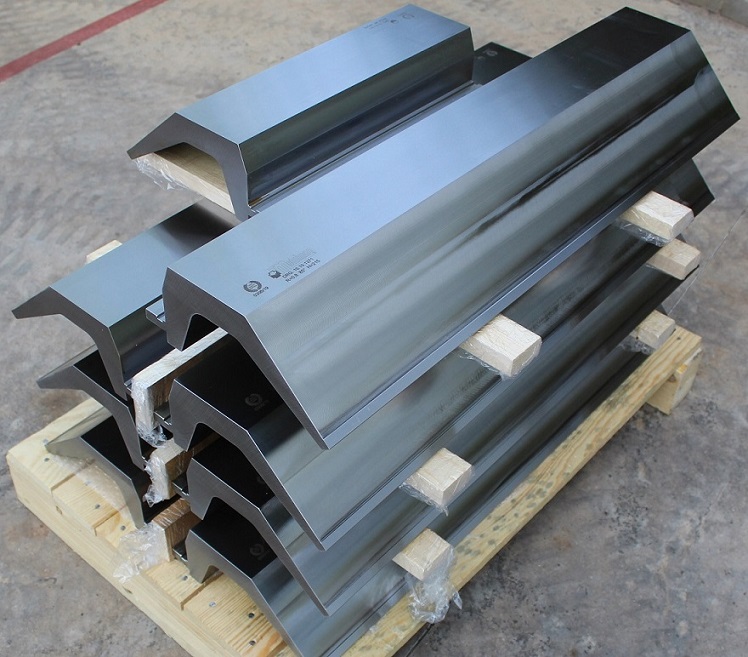

In the image below you can see the 8 punches: 7 in sections of 835 m/m and 1 in section of 415 m/m that have been manufactured.

Side view of the special punches manufactured

Top view of the special punches manufactured