METALMAQ manufactures 3 special punch holders to incorporate standard 20, 30 and 40 m/m diameter rounds, to be able to successfully bend 8 and 10 m/m sheets with large internal radii in length of 2 meters.

THE CUSTOMER ISSUE

Our client tells us that he must bend 8 and 10 m/m iron sheet, but with internal radii of 10, 15 and 20 m/m depending on the model of the piece. The pieces are “U” shaped and with very large dimensions.

The client has a metal sheet presse brake ERMAKSAN brand sheet metal folding machine of 220 Tons and 3 meters in length, with Promecam upper and lower mooring (or European system), we do a small calculation and see that with mod. 20.11/80 (with a “vee” of 80 m/m) is more than enough for the job you want to do on 8 and 10 m/m iron sheet.

THE DESIGN OF THE PUNCH HOLDERS

Our technicians design the punch holders with enough height and cleavage so that the sheet does not collide with them and can be folded with total guarantee of success.

Milling is also made in the lower part of the special punch holders to be able to fit the standard rounds of the Promecam system mod. 40.09 diameter 20, 30 and 40 m/m and to be able to change the rounds by means of screws and washers, thus facilitating the change of other diameters for different jobs and that the operation is easy and agile.

The design of the punch holder and the steel with which it will be manufactured will give the punch holder a resistance of 90 tons per meter, more than enough to bend the required metal sheets.

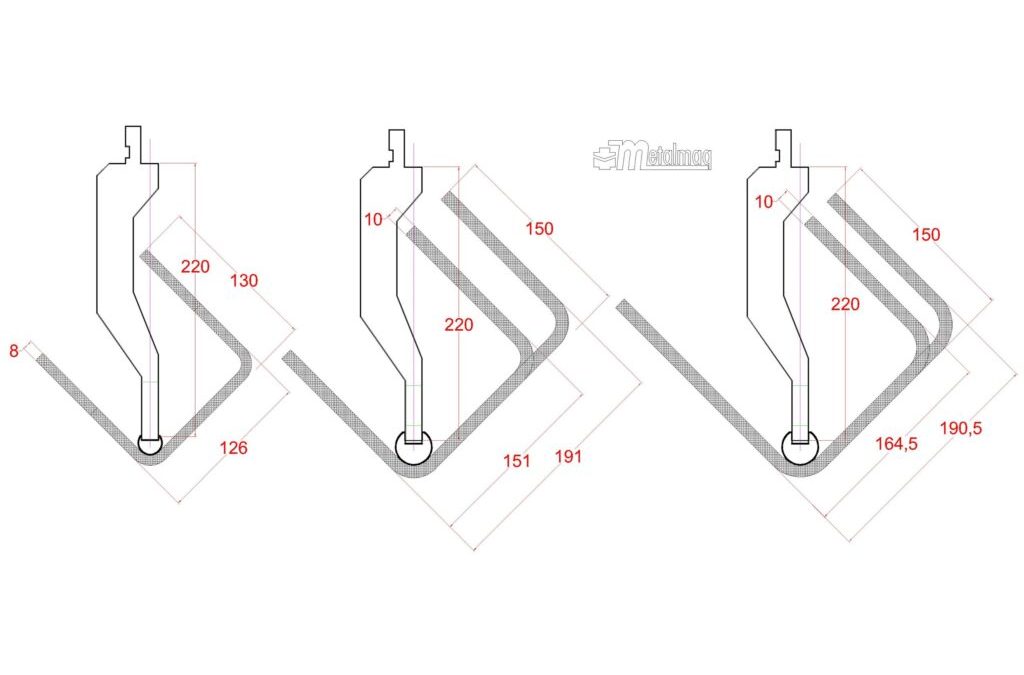

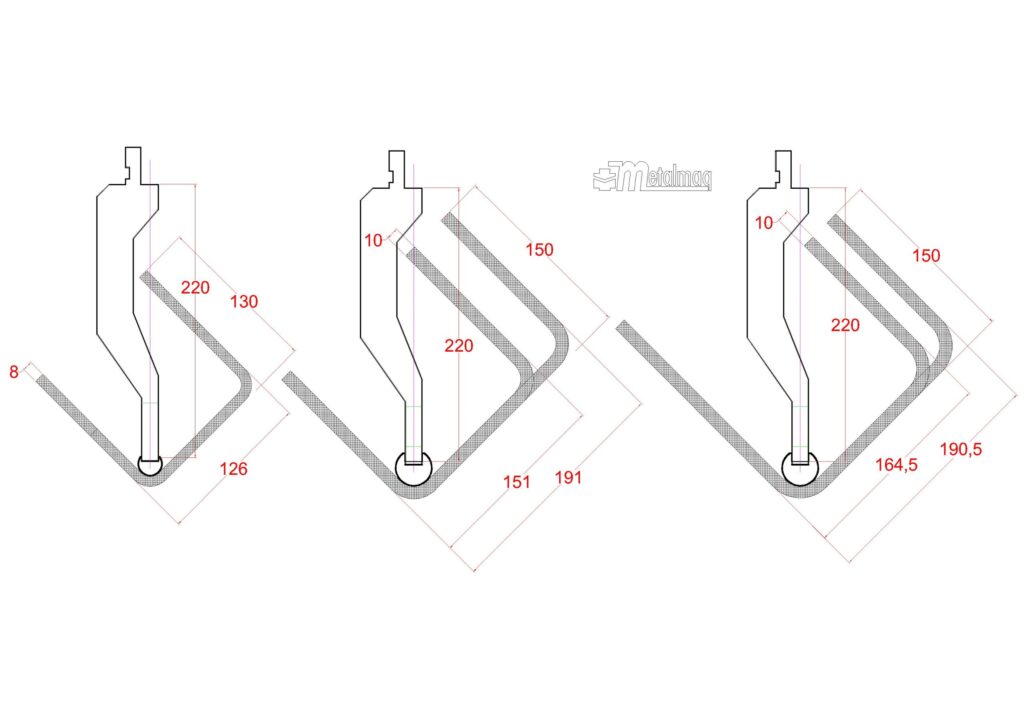

In the upper sketch you can see the punch holders that were designed with the round mod. 40.09 standard and in the simulation you can also see how all the 8 and 10 m/m sheets sent by our client can be bent.

It is also possible to observe the large dimensions of the “U”, which in the worst case has a base of 151 m/m, some “wings” of 150 m/m in length and with a 10 m/m iron plate.

THE MANUFACTURING

After verification by the client of our design and its subsequent approval, we start with the manufacture of the special punch holders.

The punch holders have been manufactured in rectified C-50 steel and have been built in 2 sections of 835 m/m and a section of 415 m/m, to be able to make the 2 meters of bending.

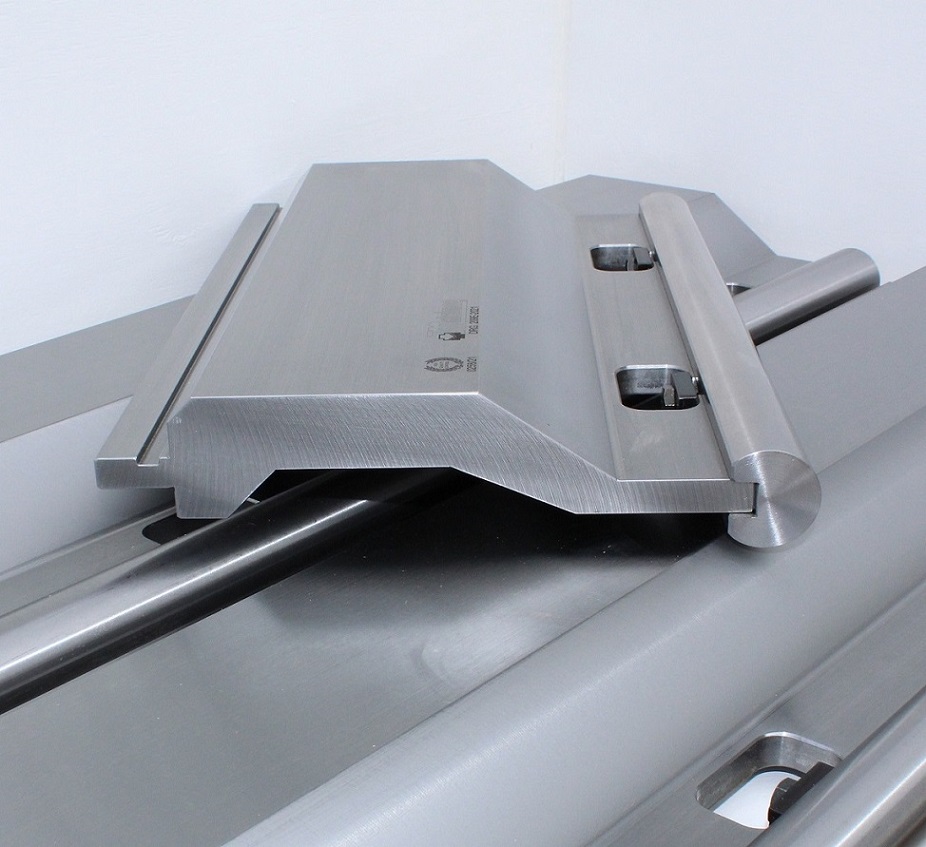

Profile view of the special punch holder

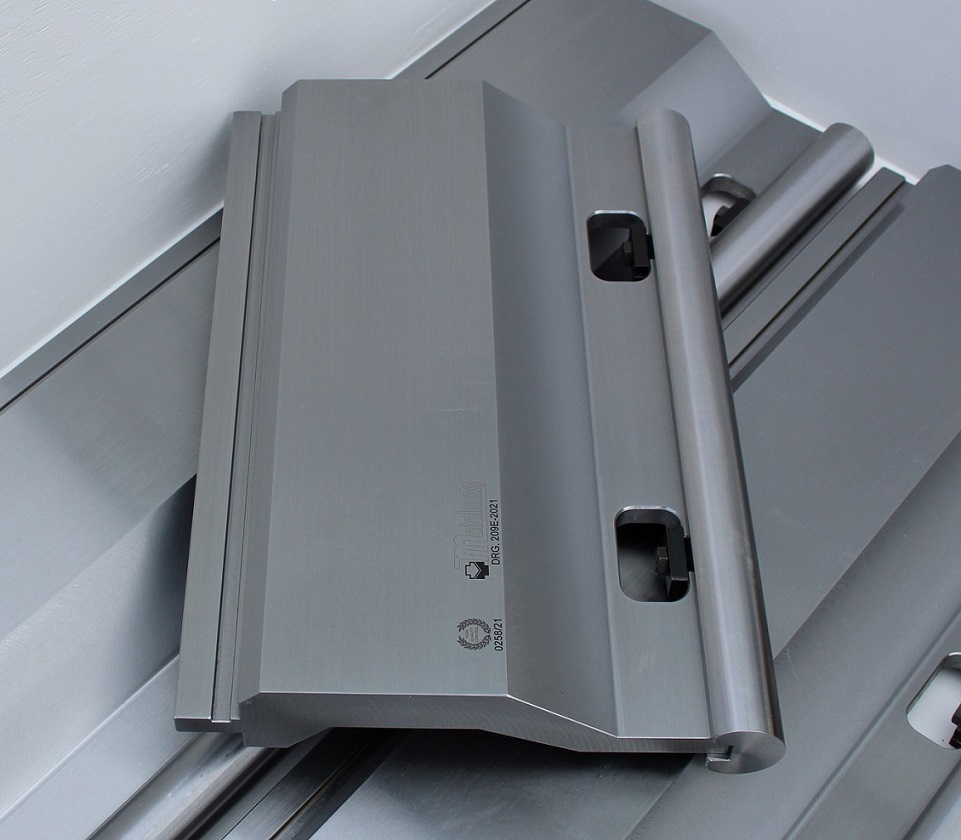

Side view of the special punch holder

In the photos above you can see the large size of the special punch holders.

View 1 of the machining of the punch holder to couple the radius

View 2 of the machining of the punch holder to couple the radius

In the upper photographs you can see the machining carried out on the punch holders so that the customer can easily change the different types of rounds.