Many customers ask us how they can turn the punch with the Promecam mooring system in their metal sheet press brake. Since, sometimes due to the design or configuration of the piece to be folded, they need to turn it to perfom said work.

Let’s see step by step, the different types of intermediaries of the Promecam system and how the turning of the punch can be carried out.

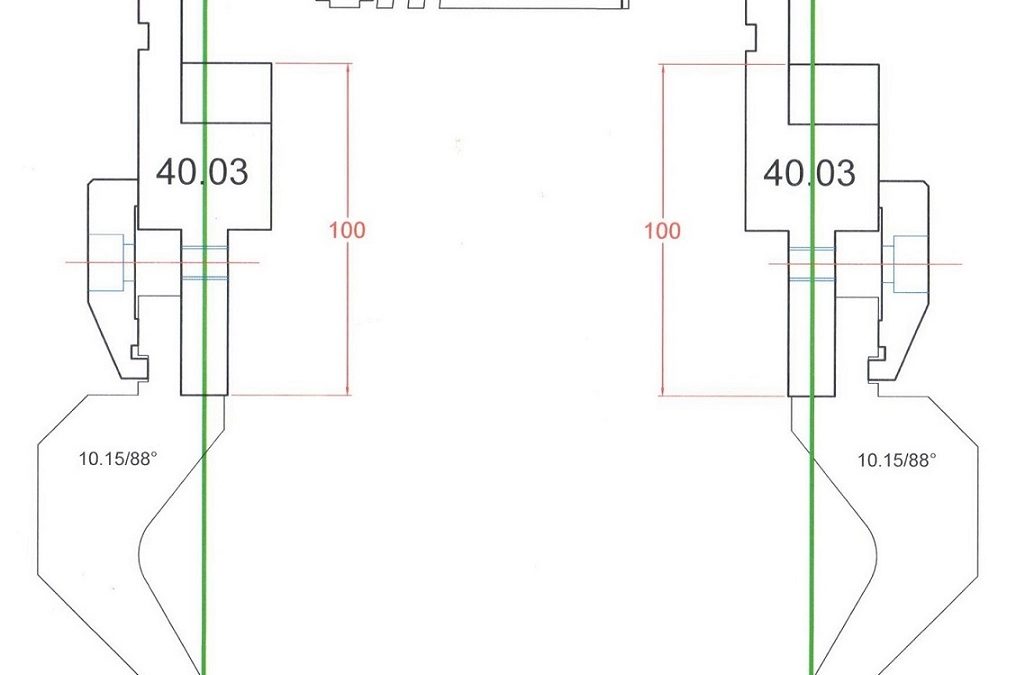

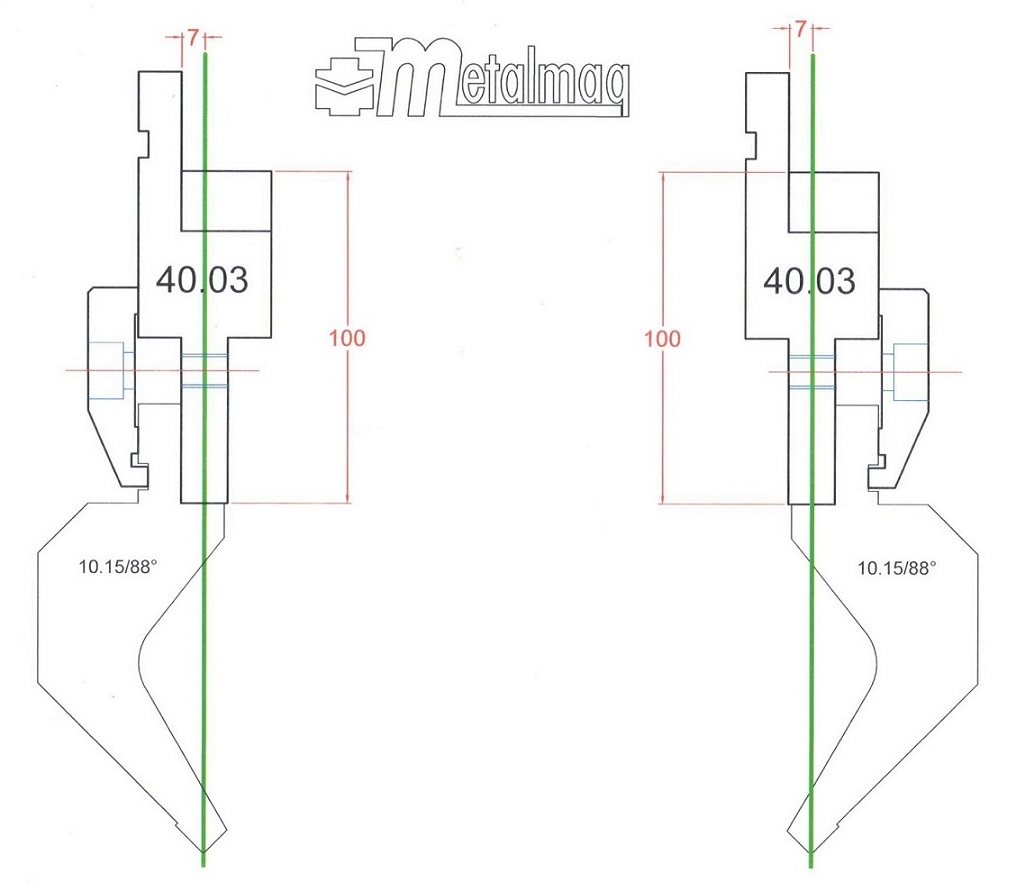

The intermediary 40.03 with useful height of 100m/m, is the most popular intermediary of the Promecam system (also known as Amada system, European system or Mebusa system) and its most important feature is that its center of bending is 7m/m from the back part of the mooring, in the following sketch attached you can see the bend line in green color, which is what will center the punch to the press brake. As we can see in the sketch only by uninstalling the front clamp (in this case mod. ST-43 with safety mooring) and mounting it on the back we can turn the punch without decentering it from the bend line (green color).

With the intermediary 40.03/150 the same thing happens as with the intermediary 40.03, since the only difference between the two is the height that goes from being 100 m/m to 150m/m, but its center of 7m/m is the same

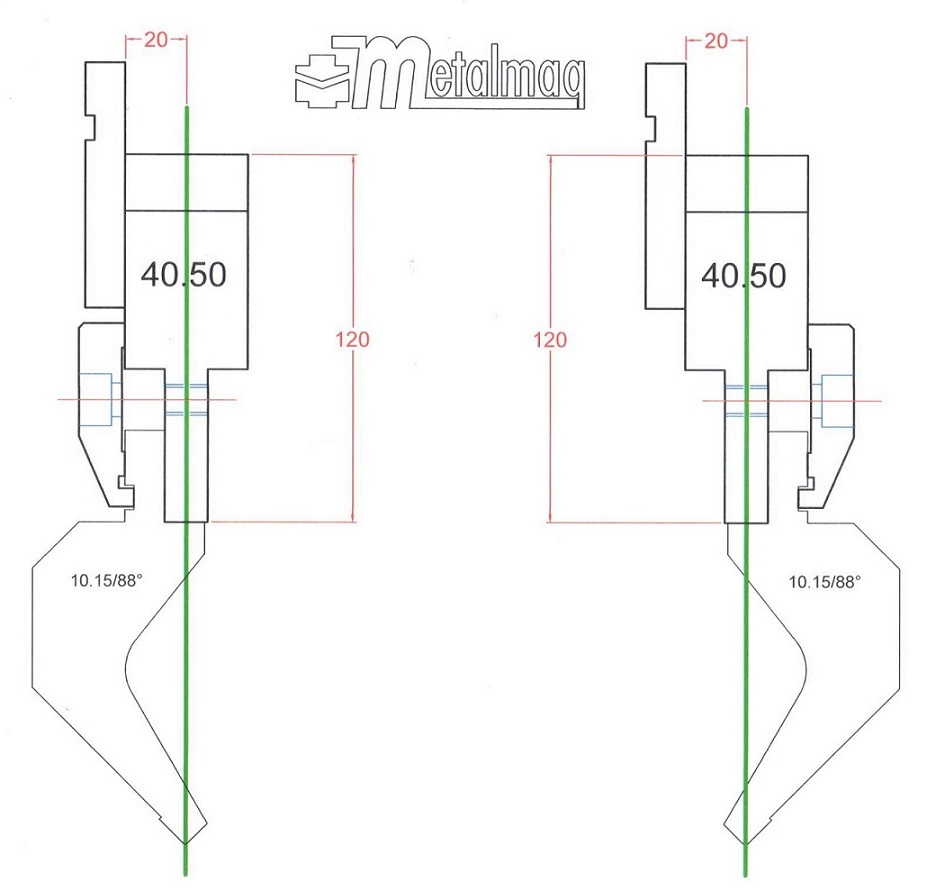

The intermediary 40.50 with useful height of 120m/m is an intermediary installed by several brands of press brakes with Promecam system (also known as Amada system, European system or Mebusa system), such as AMADA or ERMAKSAN among others and its most important feature is that its bend center is 20 m/m from the back of the mooring. In the following sketch attached you can see the bend line in green color, which is what will center the punch to the press brake. As we can see in the sketch only by uninstalling the front clamp (in this case the mod. ST-43 with safety mooring) and mounting it on the back we can turn the punch without decentering it from the bend line (green color).

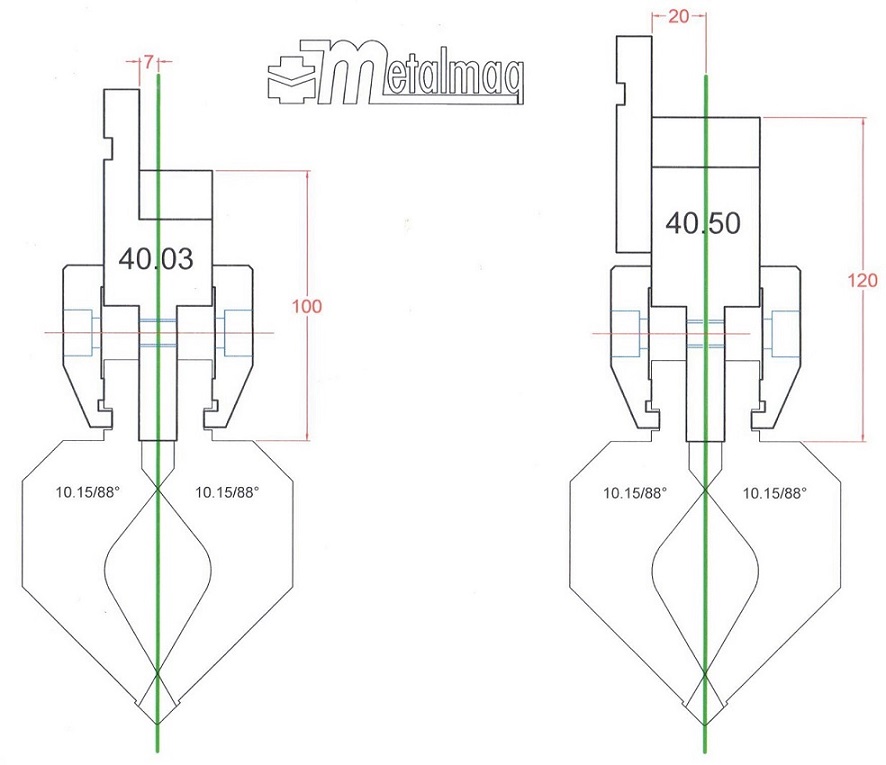

SOLUTION TO BE ABLE TO TURN THE PUNCH WITHOUT DISASSEMBLING THE CLAMP

So far we have seen how to turn the punch by turning the fastening clamp. But what if we do not want to disassemble the clamp, well then, there is also a solution! A few years ago, our Technical Office developed a KIT BACK CLAMP for coupling in all the standard intermediaries of the Promecam system and so that the punch can be turned without disassembling the clamp and, the most important, the rear clamp is operated from the front of the press brake and you should not access to the back of it, which apart from being impractical is kind of problematic.

In the following sketch we see how with the KIT BACK CLAMP we can install the punch in the position we want and even mount a section in one direction and the next in another, this is the case of some customers with complex parts and that requires to have the punches in different positions.

Finally, in the following video we see the practical demonstration of the BACK CLAMP KIT system and its ease of use in any Promecam intermediary of the market.