How can I bend Z-shaped metal sheet?

Many customers ask us the different methods and systems that exist to make “Z” shaped bends with a press brake and what type of bending tools are needed. In the next post we will see the three main methods that exist as well as a table that must always be taken into account. In the end everything will be illustrated in a tutorial video in which you can see the three ways of proceeding to obtain a metal sheet bend in a Z shape, we hope it will be very useful to you.

Method 1 – bend to bend:

the traditional method

This is the traditional method and consists in bending the piece with a standard press brake punch and die and then turning it over to bend the other side (see the video at the end of this post). The advantage is that there is no investment in tools, but it has two disadvantages; first it is a slow process and second the distance between bends (and therefore the internal measurement of the “Z”) is defined by the width of the die and is usually quite large, depending on the thickness of the material to be bended and the die used.

After making the first fold we return to present the metal sheet to proceed with the second

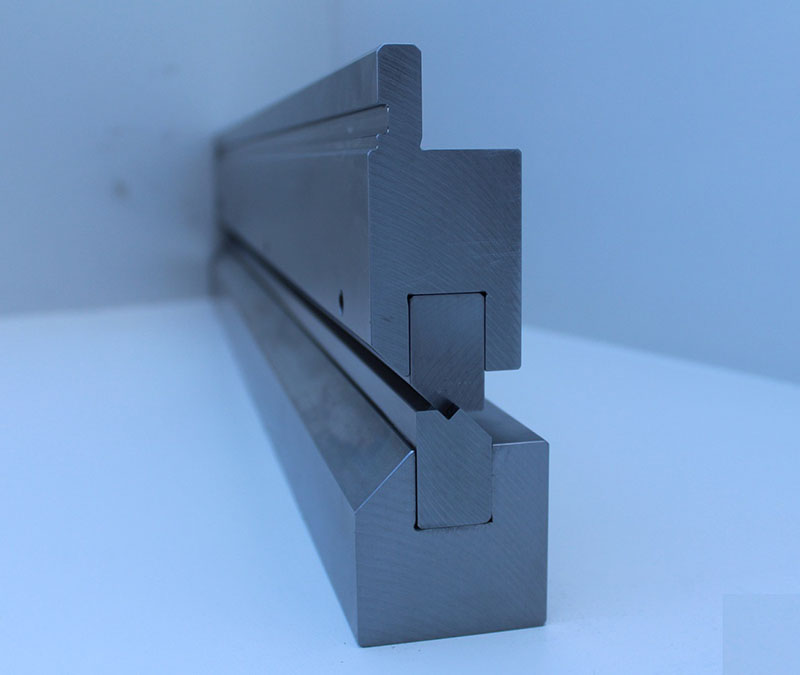

Method 2: “semi-standard” tools 40.ZP + 40.ZD:

Z-shape metal sheet bending with different sizes

With this method we speed up the bending, since from a single descent of press brake we make both bends at the same time. The “semi-standard” method allows us to change the interior inserts and to make different sizes of “Z” depending on each piece. The only disadvantage is that being “pre-defined” inserts we can have small variations in the final measure, since they are not made to measure for the required “Z”.

Detail of the “semi-standard” tool 40.ZP + 40.ZD with its “Z” insert

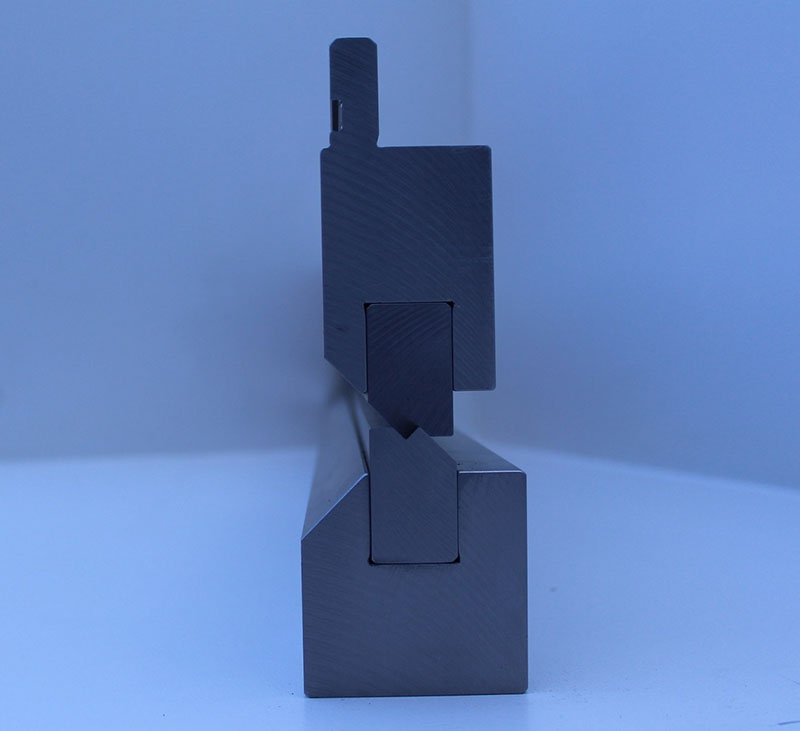

Method 3: special tool mod. 30.05:

2 metal sheet bends in a single descent of the press brake

This last method is the most reliable, since it is manufactured completely to the client’s specifications and allows us to test the metal sheet of the client before finishing the tool and to be able to test its result. This gives us a reliability of 100 x 100 and obviously an increase in productivity by making two bends in one single descent of press brake. It is the method with the highest cost, since the manufacturing is totally special, made to measure, and obviously its delivery time is longer.

Detail of the special tool mod. 30.05

Turtorial video: How to make a “Z” fold

In the next video you can see the whole process with the three methods to make the “Z” in metal sheet press brake.

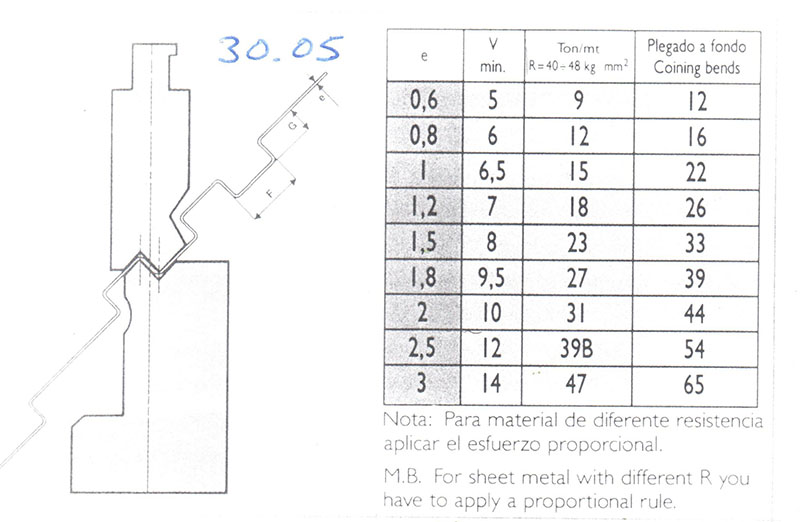

Table of tonnage for metal sheet bending in “Z”

It is also important to know that in all tools that make two bends at once (as it is the case of bending a “Z”) the tonnage needed to bend the piece increases considerably, depending on the thickness and the type of material, as you can see it in the following table: