It is very normal to find press brakes with special moorings (not standardized by the market) on the market, this causes a big problem for its users, who do not find punches and dies for immediate delivery, or at such a competitive price.

SPECIAL PUNCHES

Many times we find folding machines with special punches (not standardized) on the market, with the consequent problem, since if they must be manufactured, their prices are high and their delivery times are very long. Old folding machines such as Haco, Casanova, Nova-Europ, Arrieta, etc. usually have this type of punches.

SOLUTION

One of the most widespread solutions to change the special punch for standardized punches is to make special adapters to change the mooring of the press brake.

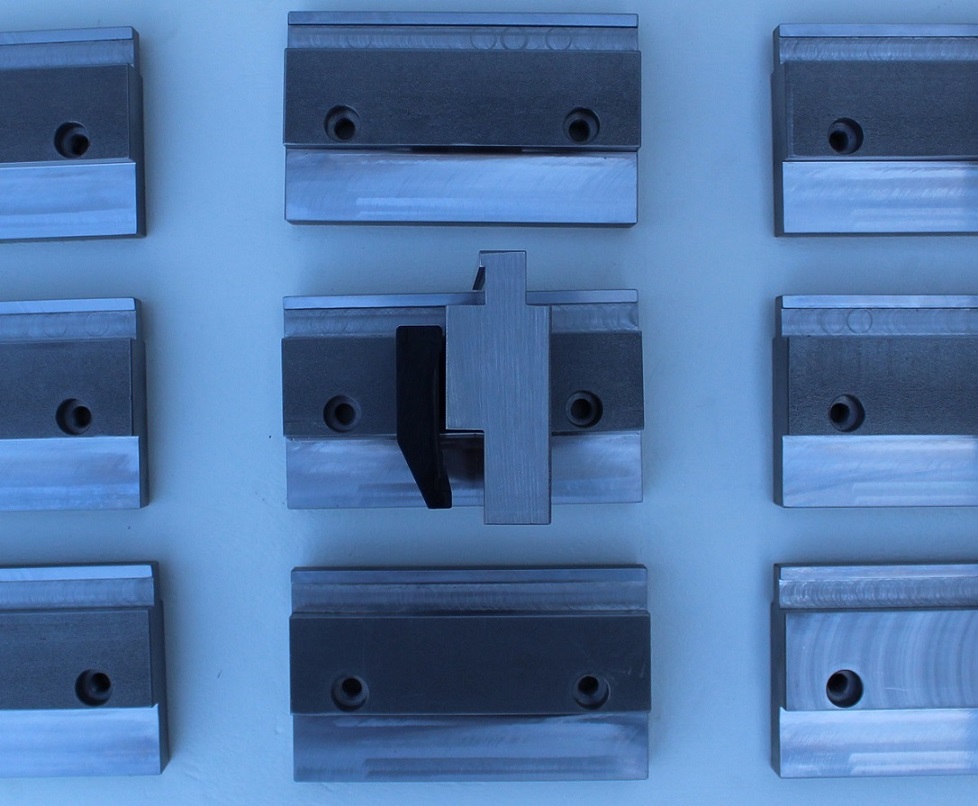

In the following photos you can see different adapters manufactured for some of our customers.

Special adapters to standard mooring Promecam

Special adapters to switch to standard mooring Promecam

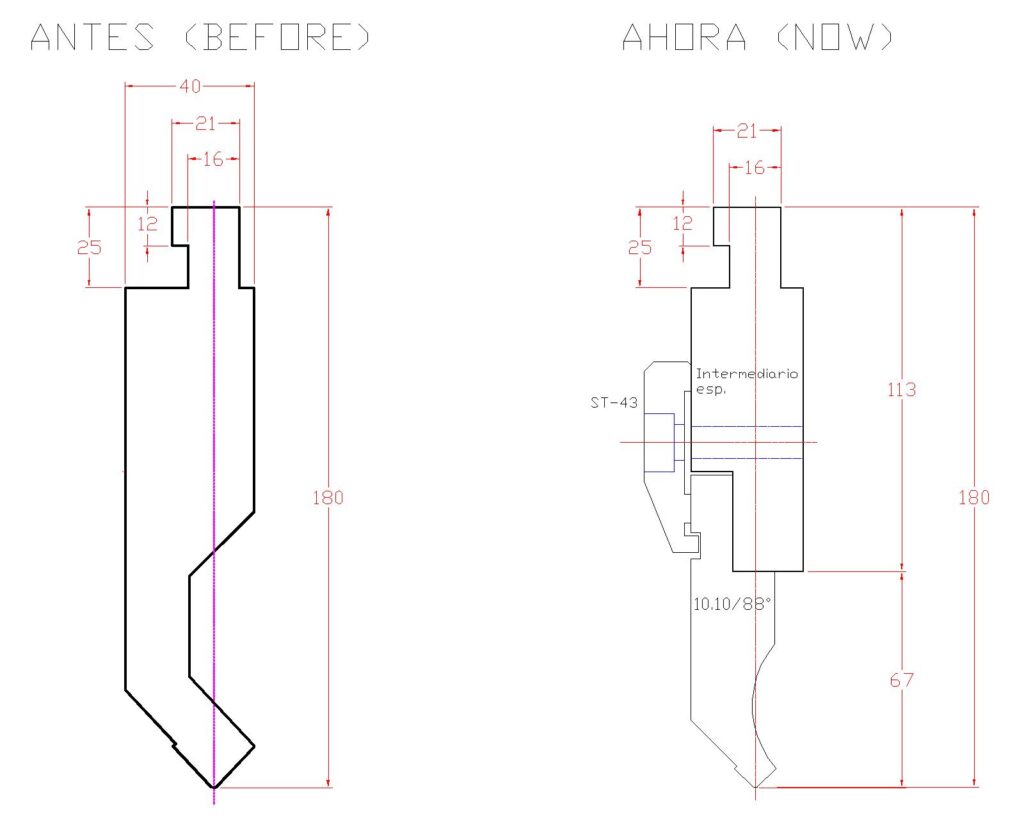

In the following design you can see the old special mooring and the new proposed solution. With this solution the clamping is changed to a standardized one, therefore from now on the replacement and change of new punches will be faster and cheaper.

As can also be seen, the special punch has a total height of 180 m/m, so when we design the adapter we try to make it of a height that adding the standard punch chosen by the custyomer adds up to the same height as the punch before (in in this case 180 m/m) and thus not change heights or strokes of the customer’s press brake.

In the sketch on the left (BEFORE) you can see the punch that had the original press brake and therefore special. In the sketch on the right (NOW) we see how a special intermediate is manufactured to go from the special mooring to a more usual mooring, in this case the Promecam system.

As we can see in the second sketch, the Promecam punch (mod. 10.10 / 88º) is held by the ST-43 clamp, but we also have the option of putting a quick lever clamp, like the ST-50, and so avoid the tightening operation and loosen screws to change the punches.

In the following video you can see how time is saved with this type of quick clamp ST-50;

MORE ADVANTAGES

Another great advantage of the change to the intermediary system is that we manufacture them in sections of 150 m/m. Each meter usually takes 5 units, so for a press brake of 3 meters we will install 15 units of special intermediaries and their corresponding clamps; or the manual ST-43 or the ST-50 with quick lever. As it is manufactured in sections, it is a great advantage, since it allows us to use the height of the punch + the intermediaries to, for example, make closed boxes and drawers, thus gaining a lot of height.

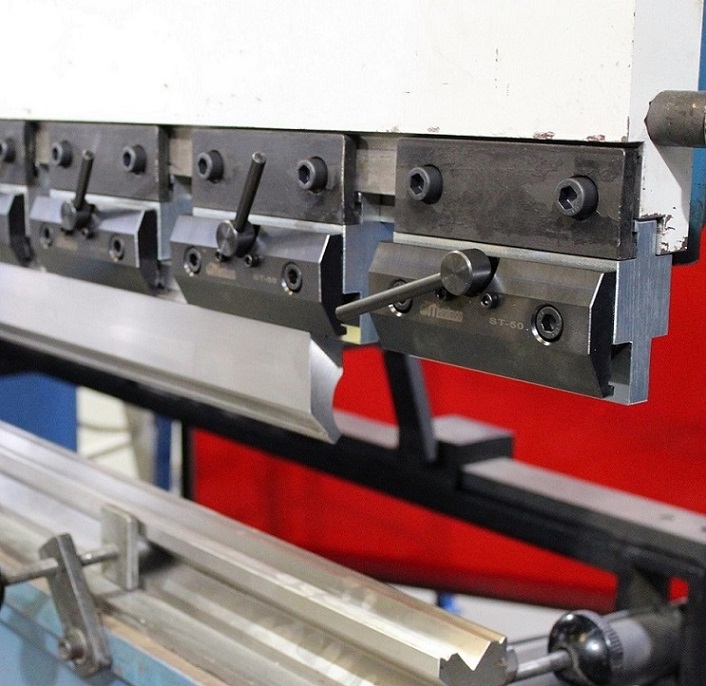

In the following photograph you can see the installation of special intermediaries in a press brake of 3 meters with the quick mooring clamp ST-50.

Retrofitting of a press brake with special mooring

Press brake with special intermediaries to move to mooring Promecam

Detail of the intermediaries with the quick clamps ST-50 and the standard punches mod.10.10/88º type PROMECAM.

SPECIAL DIES

Another problem that users of old press brakes usually have is the die. In the past, the die was sized according to the tonnage of the press brake, that is to say, if the press brake was 3 meters and has a tonnage (force) of 150 Tons, the die can be 130 x 130 m/m in size and with a maximum V of 100 m/m. But sometimes the client works metal sheet of 1, 2 and 3 m/m and never has to use this type of large and dimensioned die.

SOLUTION

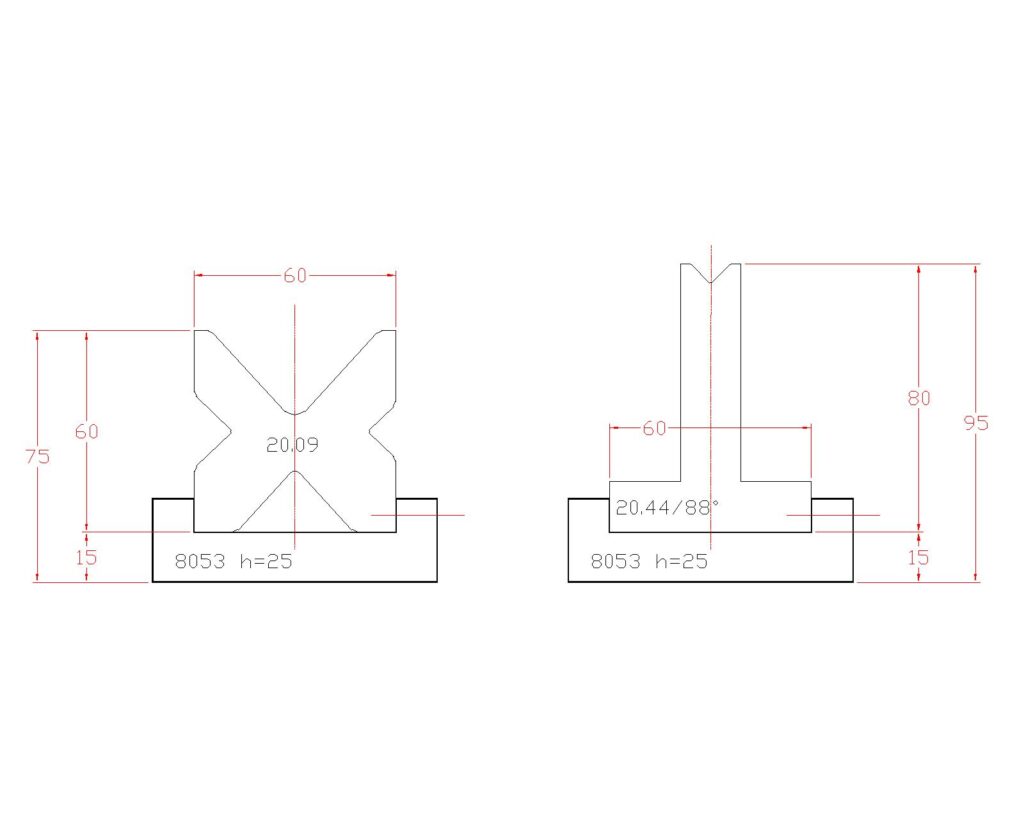

A possible solution for customers with very large dies, but who only work with thin thicknesses, is to install a box (type mod. 8053) to be able to couple dies type Promecam at 835 m/m and 415 m/m sections.

In the following sketch you can see the installation of the die holder mod. 8053 with dies type Promecam. It is important that the box is in one piece and it is highly recommended that it has the length of the press brake, although not all the dies are purchased in their entire length, but at least we leave the guide ready for the future.

In the sketch on the left you can see the box mod. 8053 with the die type mod. 20.09 and in the sketch on the right you can see a die mod. 20.44/88º with V of 12 m/m, the so-called T-type dies. These dies, having the “vee” centered and at a short distance from the edge, are perfect for making counter-folds and also for placing fractional dies to be able to make inverted drawers, among other jobs.

Another advantage of doing this type of installation is that the box mod. 8053 is always centered and the operation of centering the multi-vee die each time is avoided, which is always a significant waste of time when changing the “ve”.