Incorporation of new dies in METALMAQ’s standard production to meet the needs of our customers from all over the word.

THE MARKET

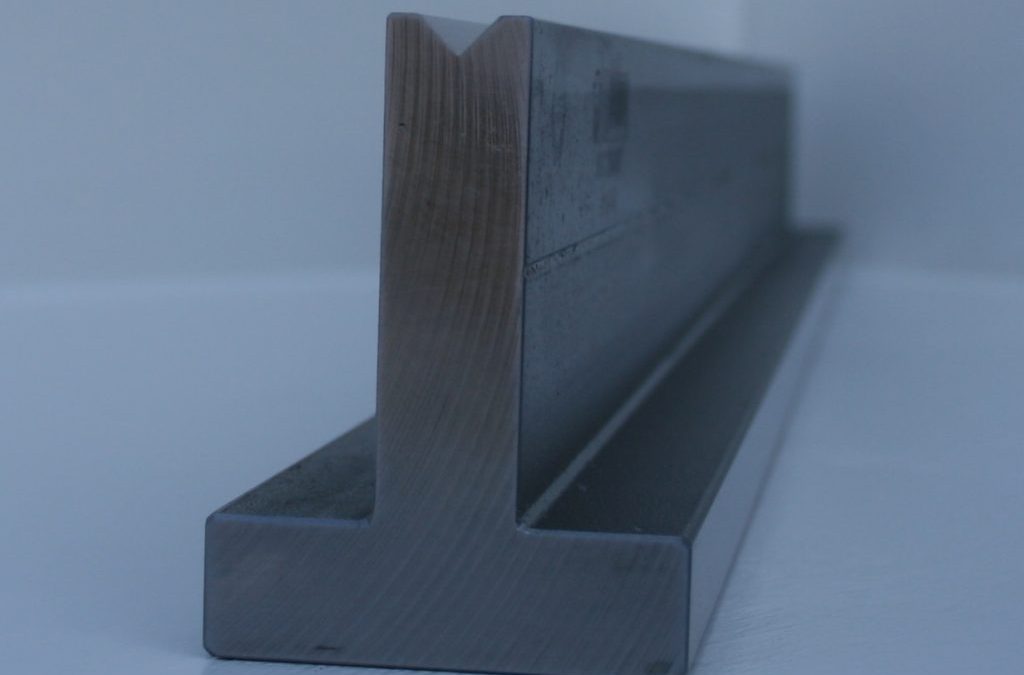

Promecam type dies are one of the best-selling families of press brake tools and of these, the T-shaped dies are the bulk of our sales. We call them T-shaped because they are in the form of an inverted T, with a 60 m/m base and the V-shaped notch in the high and narrow part.

The typical shape of these dies where the V-shaped notch is in the upper part can be seen in the picture below. This allows us to always have the V-shaped notch at the end, which is very practical for making counter-bends. These dies are supplied in whole sections of 835, 415 m/m and also in fractioned sections of 835 m/m. These come in sections of 10 – 15 – 20 – 40 – 50 – 100 – 200 and 400 m/m, being very practical for bending boxes or trays that have downward bends, in which the die must be made to measure in order to avoid collisions in the bending operation.

THE RANGE

T-shaped dies are manufactured with the 6, 8, 10 and 12 m/m V-shaped notch at 90º, having the 6, 8, 10, 12, 16 and 20 m/m V-shaped notch at 88º and the 25 m/m V-shaped notch at 85º.

They are also manufactured with the 6, 8, 10, 12, 16 and 20 m/m V-shaped notch at 60º, and lastly with the 6, 8, 10, 12, 16 and 20 m/m V-shaped notch at 35º.

They are also manufactured with the 6, 8, 10, 12, 16 and 20 m/m V-shaped notch at 60º, and lastly with the 6, 8, 10, 12, 16 and 20 m/m V-shaped notch at 35º.

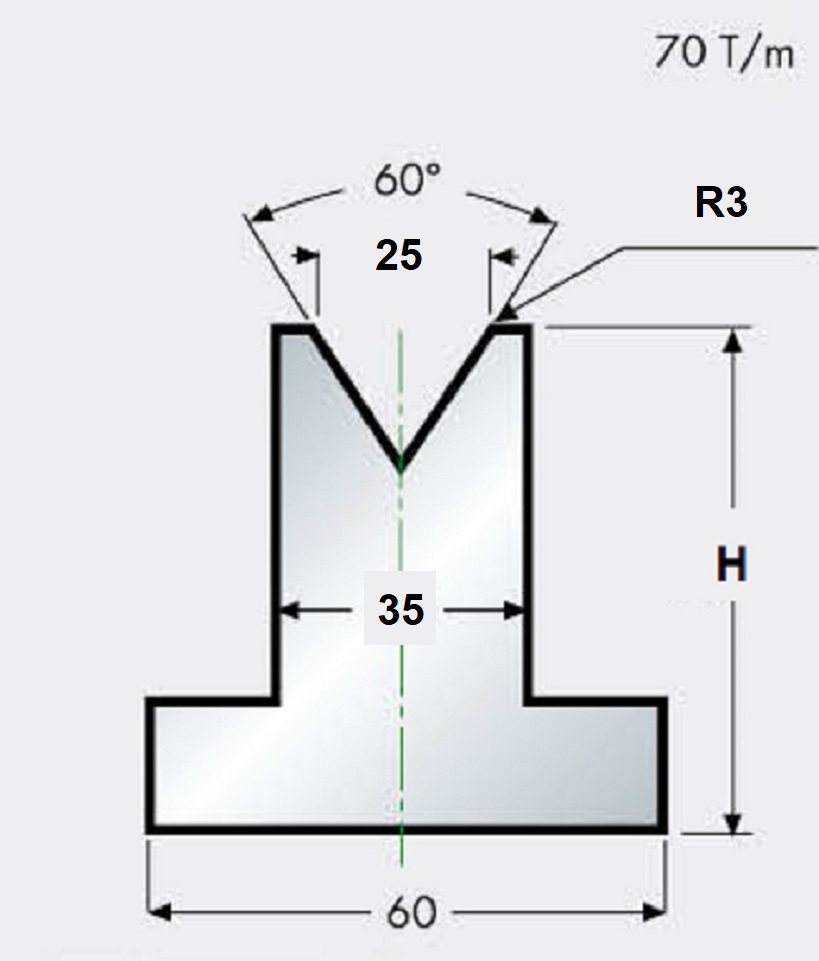

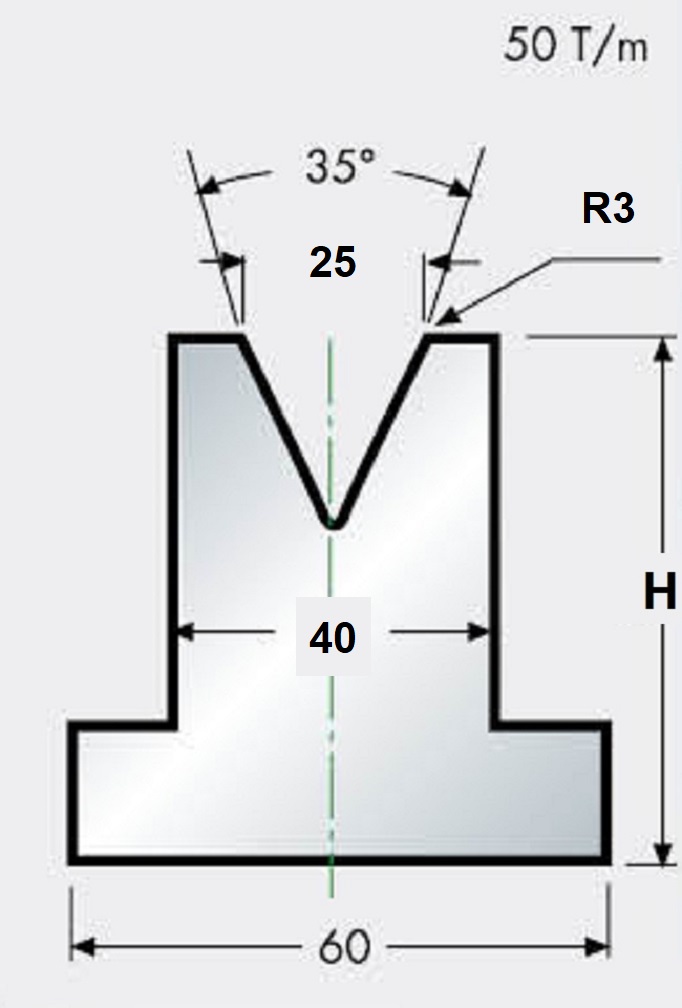

No sooner was this said we did it. We have created a new range with the 20.47/60º model die, which is a 60º die with a 25 m/m V-shaped notch. We have also created the new 20.47/35º model, which is the 35º die with a 25 m/m V-shaped notch, thus completing the range of the best-selling family of press brake dies.

The following sketches show the two new die models that we have incorporated in our standard production.

80 m/m and 120 m/m HEIGHT

This type of die was manufactured a long time ago at the 60 m/m height. Later on, it was also produced at the 80 m/m height. After that, the 60 m/m height was discontinued and only the 80 m/m height was produced.

Over the course of time, many customers asked for larger heights and then the 120 m/m height was standardised as an “option”. At first they were made to order, but little by little customers have been using them more and for some time now, the 80 m/m height as well as the 120 m/m height have been standardised.

T-shaped dies are in STOCK with both heights (80 and 120 m/m) and with all the V-shaped notches and angles, in order to provide optimal service to our customers and collaborators.

CONCLUSION

The conclusion is clear: we are always attentive to market movements and to the requests of our customers to always try to provide good, fast, and cost-effective solutions.