BIEMH 24 and Metalmaq 30 years together. That’s right, Metalmaq started exhibiting at the Bilbao machine and tool fair (BIEMH) in 1994 and has never missed it on any occasion (except for 2020, when it was not held due to the pandemic). This year the celebration took place from the 3rd to the 7th of June 2024.

OUR STAND AT THE BIEMH

As we have been observing year after year, trade fairs are becoming less and less important for our business, so we have long since decided to continue going, but without very high costs, i.e. with a small stand and few staff.

As you can see in the photos below, our stand was 20 m2 and we had a number of displays with our press brake tools and accessories, also equipped with screens to show demonstration videos of our latest products.

We presented the latest developments, which are becoming increasingly more numerous, and we were able to give explanations to anyone who was interested in them.

PRESENTATION AND NEWS

On this occasion we are presenting several very new products that we have not physically presented since the previous fair. They are listed below them from the oldest to the newest;

i-LASER LINE 30mW for press brake

This is the second laser line drawing system that that we are launching on the market after the success of the DIE’S LASER LINE. Its main feature is its high-power laser line (30 mW), which is plugged directly into the mains, and you can even buy several accessories to install it in press brakes, making it extremely practical to aid in the bending operation and to align the pieces with the bending line with a full guarantee.

In the following video you can see this NEW laser system, its advantages and how its accessories work:

Laser Slag Cleaner

Due to all the enquiries we had and as increasingly more of our customers are purchasing a cutting laser, we decided to start producing and marketing our own “LASER SLAG CLEANER”.

The particularity is the way the blades work, as they “embrace” the fakir slats and remove the slag easily and without tool wear. In the following video you can see how it works:

Magnetic Template 120×120

The Magnetic Template is a very new product that does not exist on the market. Inspired by our customers, we created a template with a magnetic base to hold it in press brake dies. With it, our customers can create their own pattern (a negative) with their laser cutter and have a template for bending parts that are very complicated to bend using a traditional method (with back stops, for example).

As a picture is worth a thousand words, in the following video you can see the presentation and how parts are bent in a way that can hardly be done with a normal stop:

Pneumatic hammer parts separator

Due to the success of the Laser Slag Cleaner, this Pneumatic Hammer is the ideal companion for separating parts after laser cutting.

As you can see, we are always innovating in products and tools that facilitate, speed up and provide extra safety to our customers.

In the following video you can see the Pneumatic Hammer in full operation and with videos sent by our customers:

DIE’S LASER LINE PLUS 30mw

The success of the i-Laser Line 30mw led us to overhaul the first DIE’S LASER LINE and equip it with a laser 3 times more powerful and with a power plug, i.e. no more changing batteries.

In following video you can see how it works and the power of its new laser:

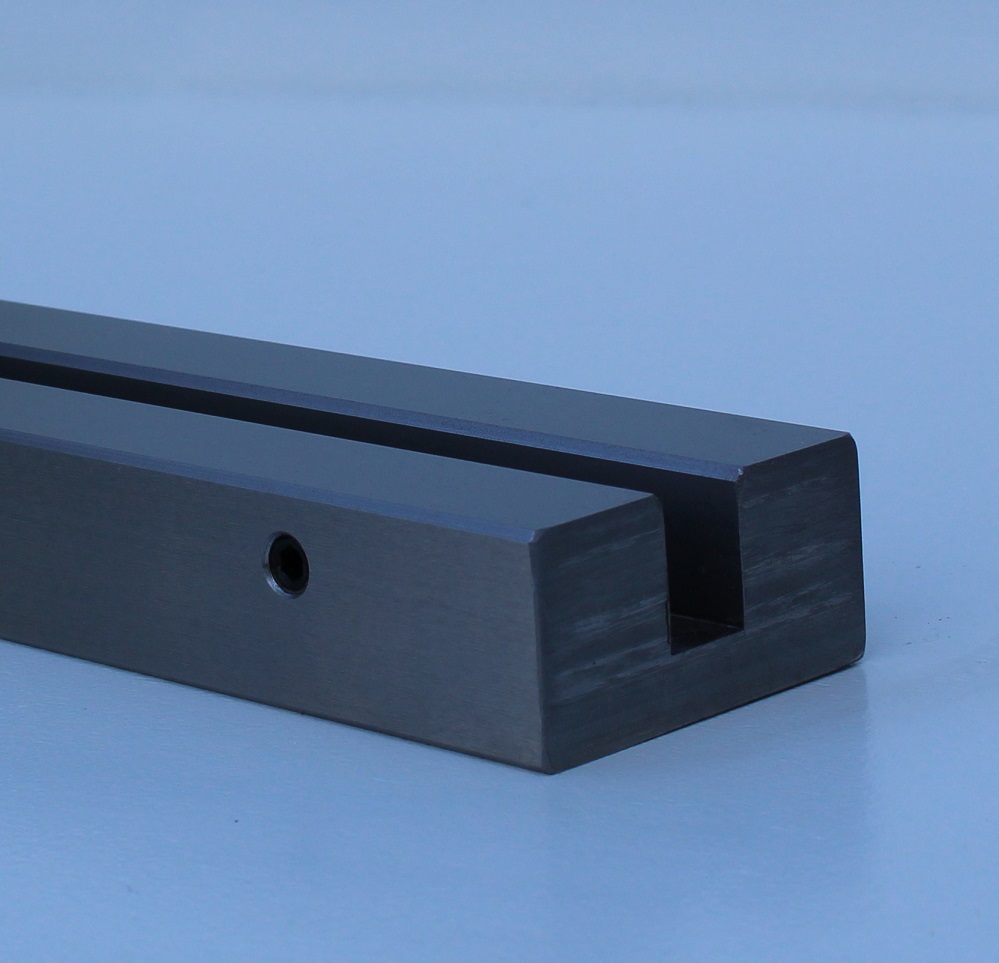

SPE 40.01 Intermediate Speed to Promecam

We standardised an intermediate to switch from the SPEED system (Beyeler-Wila-Trumpf clamping) to the Promecam system and thus achieved an optimal price and immediate delivery.

Manual Template 120×120

Due to the success of the Magnetic Template we decided to create this manual version, as when the die is a multi-vee or its clamping wall is not flat this version can perform better than its magnetic “sister”.

In the following video you can see how the NEW Manual Template works;

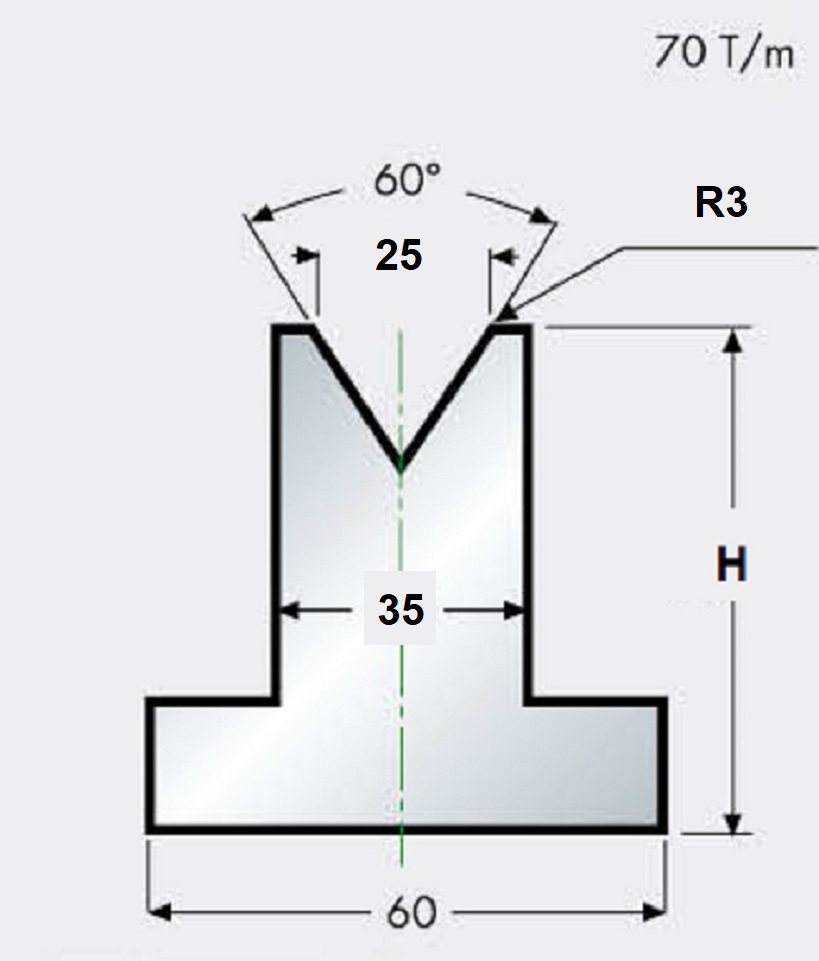

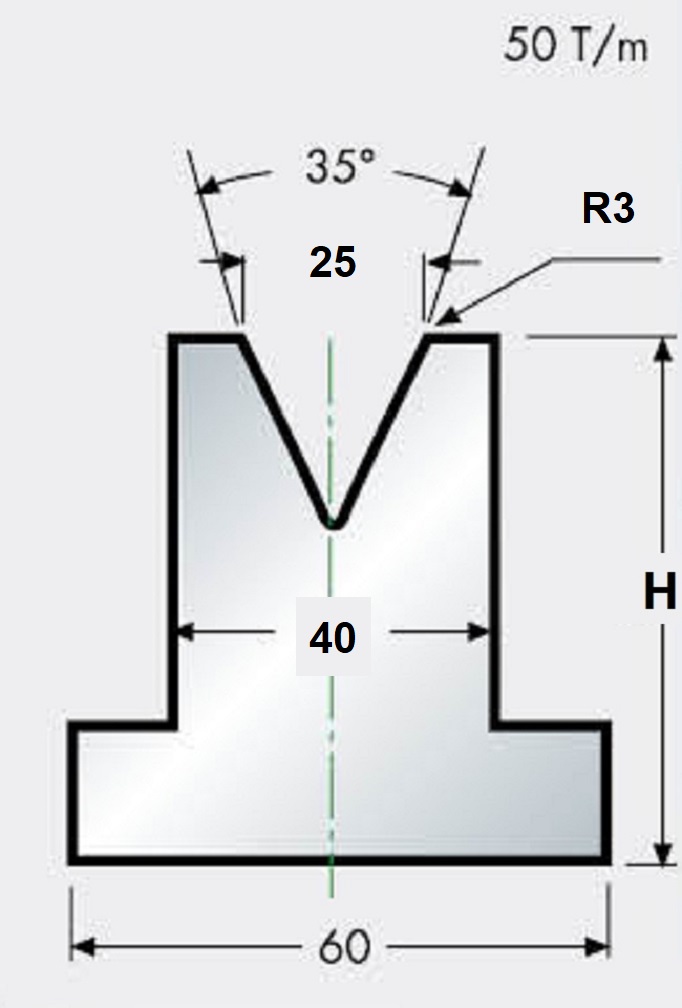

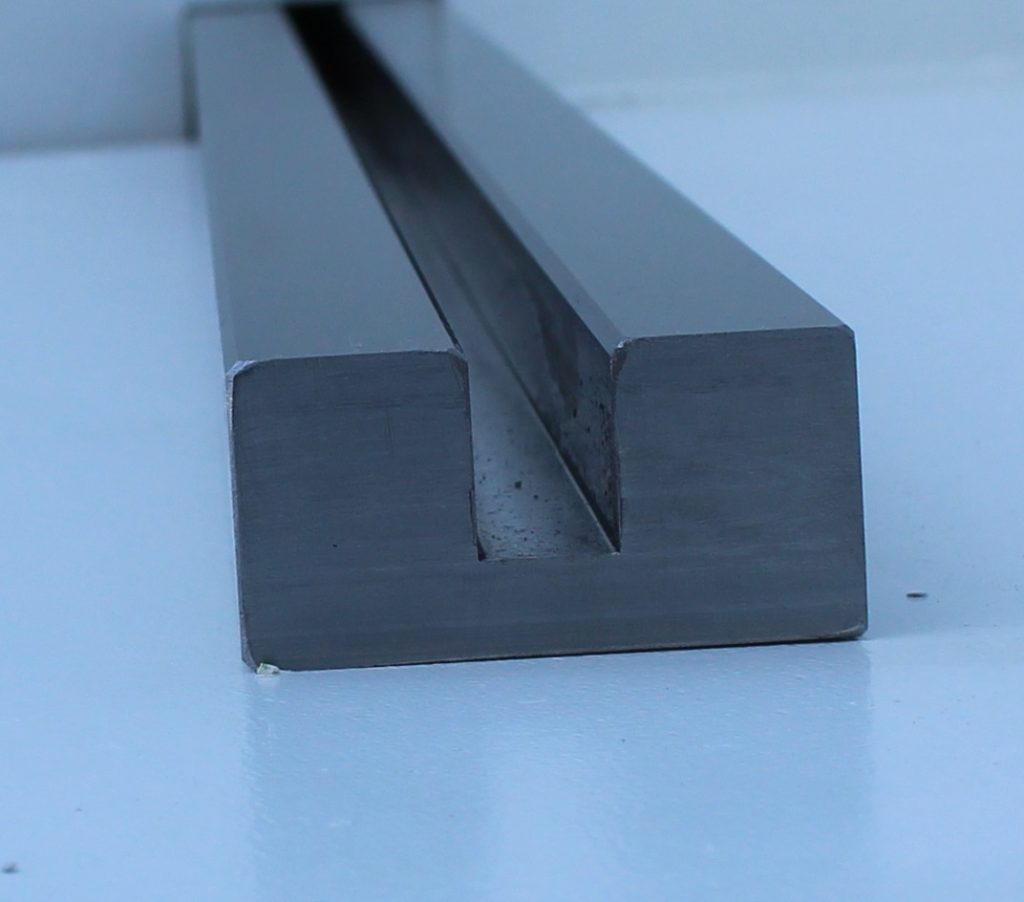

Die mod. 20.47/60° and mod. 20.47/35°

Inverted T-shaped press brake dies are a product in very high demand lately, and with these new additions we complete the range by adding the 25 m/m V shape at 60° and 35°.

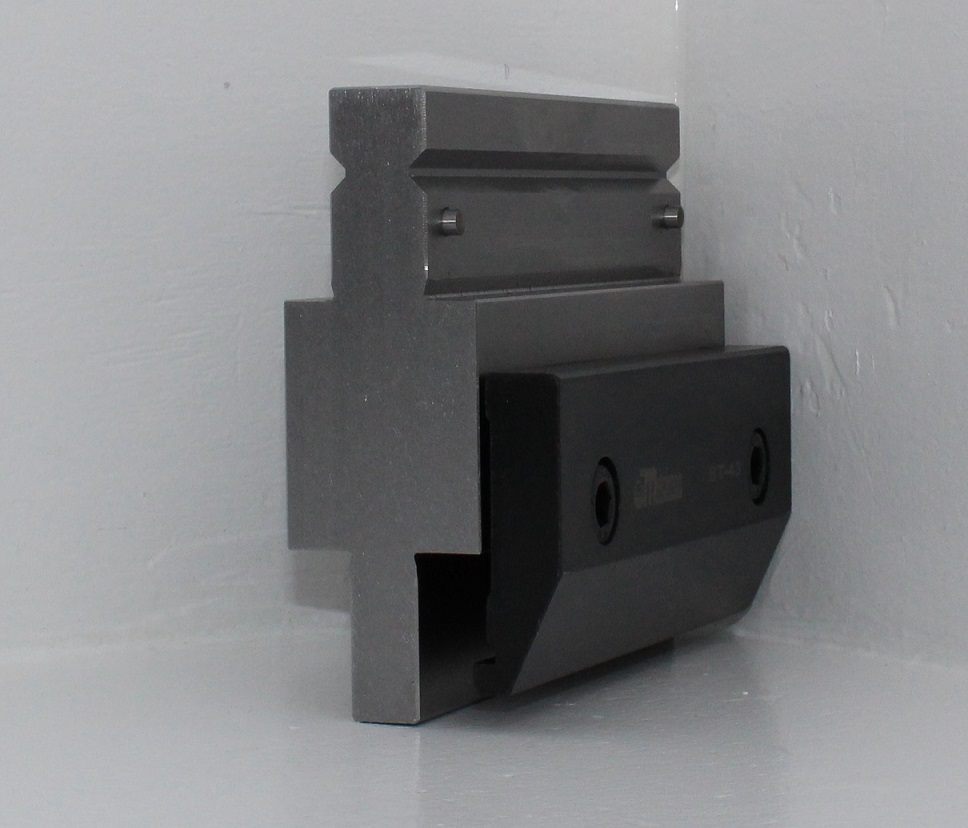

8060 Promecam-Beyeler die holder

In order to support the change of clamping and the standardisation of press brake dies, we have standardised the 8060 die holder, so that a Promecam clamping can be switched to a Beyeler-“Bystronic” System-Wila–Speed-Trumpf clamping without any difficulty.

As always at the BIEMH fair, we explain what our incessant R&D is working on, but for those of you who couldn’t come to the fair you will have to wait for the next one or keep an eye on our Online presentations.

CONCLUSIONS AND FEELINGS

The fair is not what it was years ago in terms of crowds, but it is still a meeting place to meet real people and discuss work and non-work issues in a relaxed atmosphere.

In the following photos you can see our area delegates, always ready to serve our customers with a big smile.