METALMAQ manufactures a special tool for bending a 10 m/m thick, 24° angled platen, for a joint project with the manufacturer FEYSAMA and its customer located on the African continent.

WE ARE TRAVELLING THE WORLD AGAIN

Our customer is a press brake manufacturer (FEYSAMA) and must supply a press brake to his customer in LA MAYOTTE, an island located on the African continent, between Mozambique and the island of Madagascar. As we can see and as has come to be seen as the norm lately, our products have no border and go from the USA to New Zealand without any issues.

THE SOLUTION

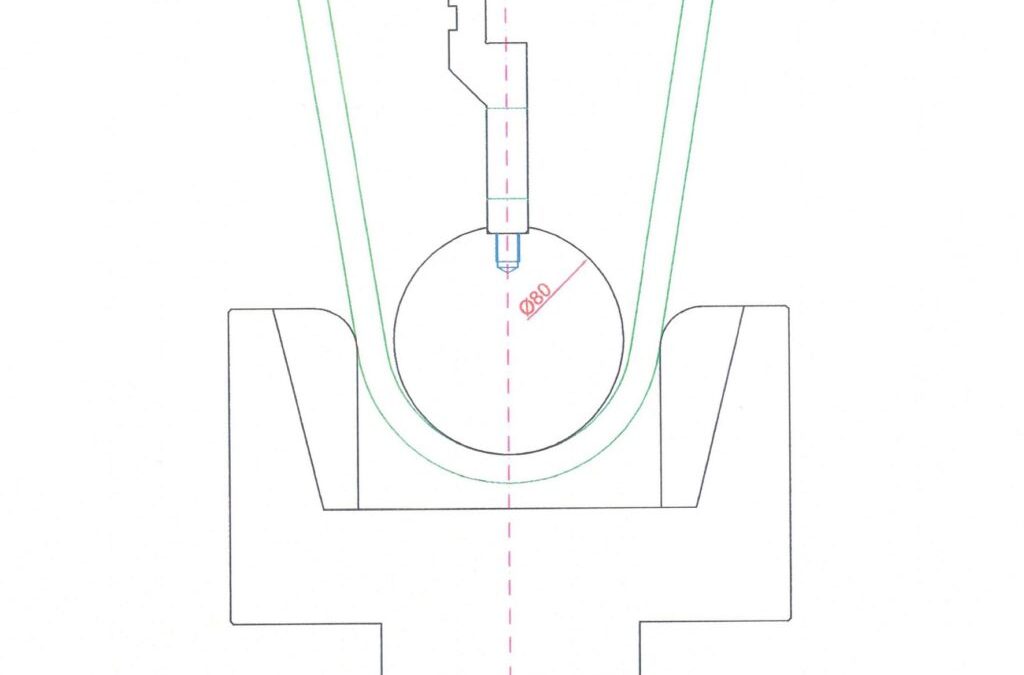

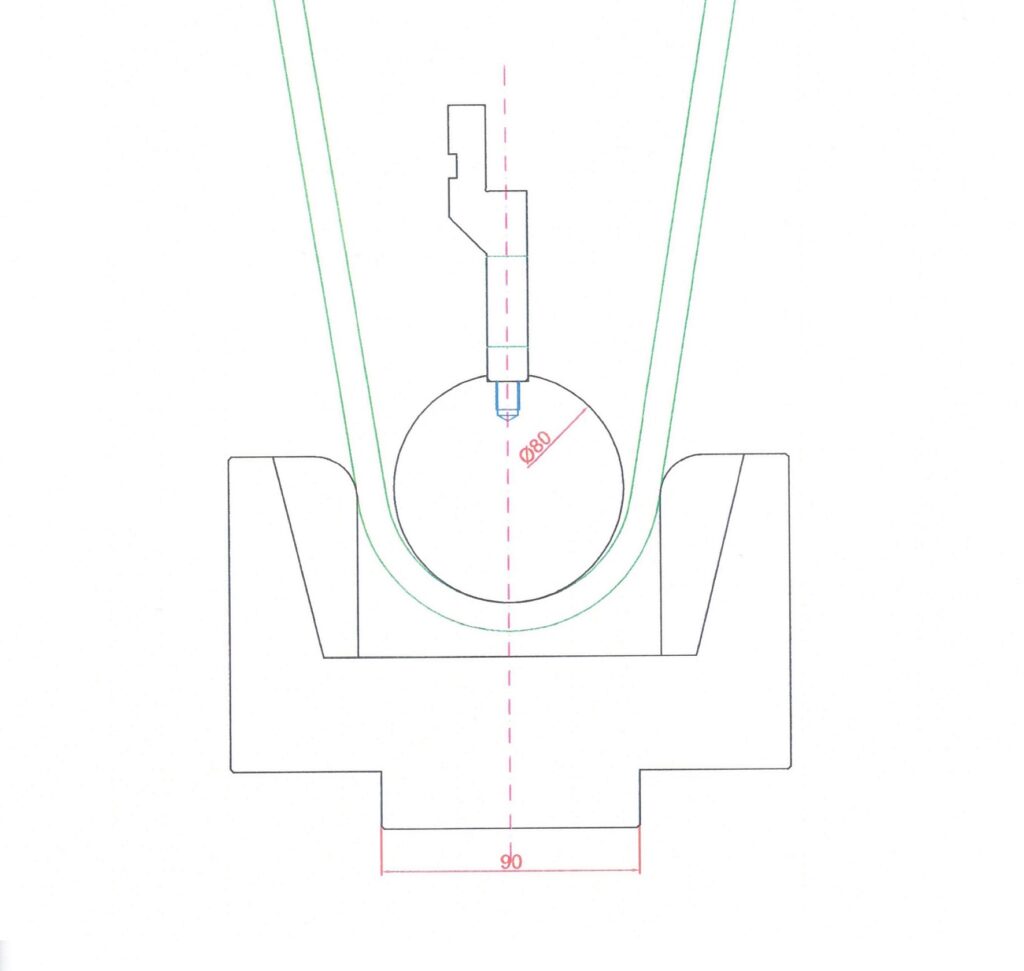

Our technical office designed a tool with a Promecam clamping system (or European clamping) that bends the 10 m/m thick sheet, with an inner radius of 40 m/m and at a very tight angle of 24°. As can be seen in the sketch below, the tool has been designed with two side wedges so as to enable the very easy removal of the piece once it has been bent.

Wedges are a system widely used by METALMAQ and work as follows: When the press brake exerts downward pressure, the wedges help to close the piece, and when the press brake “opens”, the wedges are released, having upward play causes them to open the opening of the piece location, which facilitates removal of the bent part.

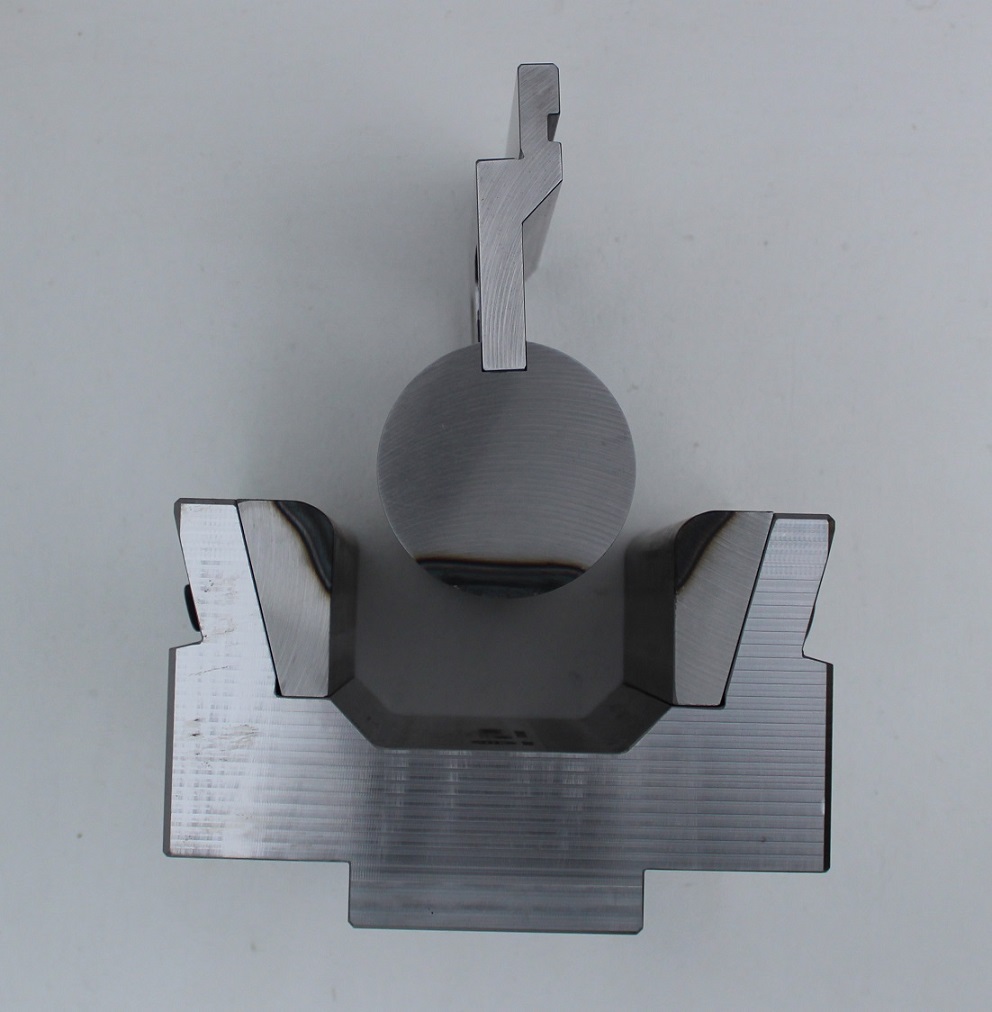

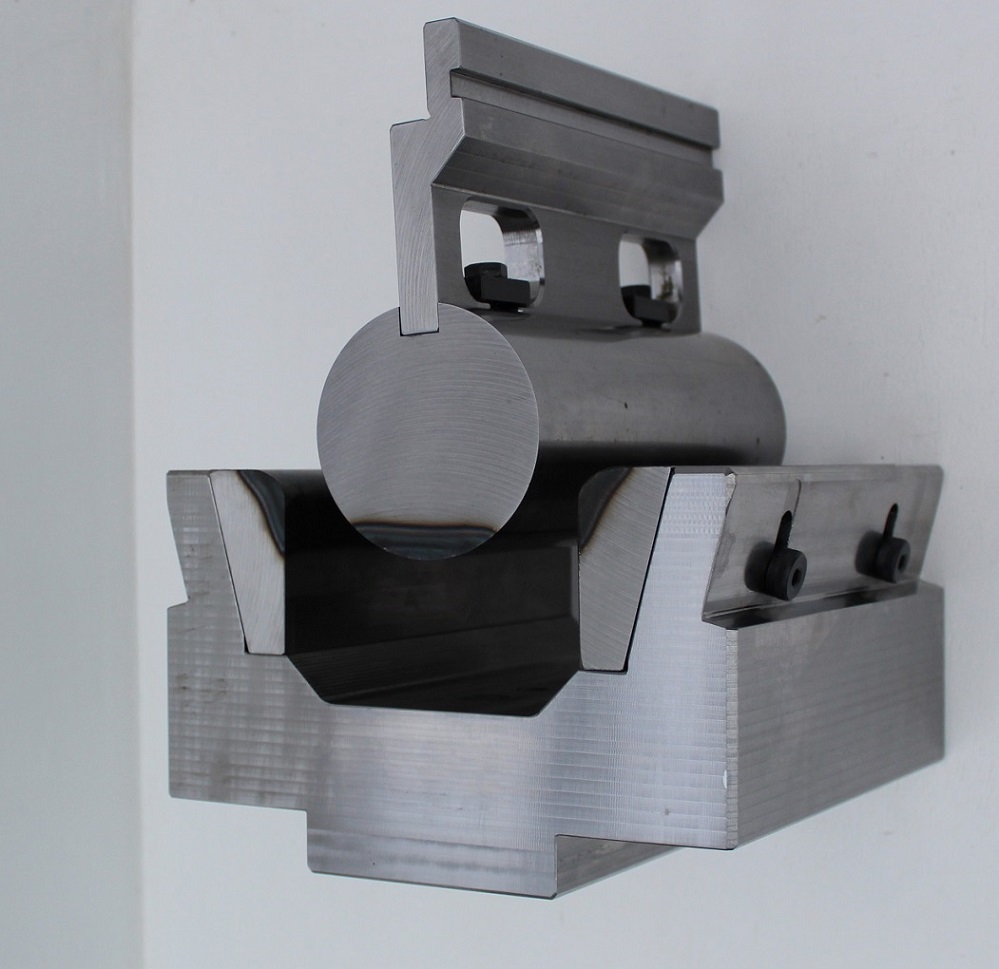

The above photos show the special tool manufactured, where the upper part consist of the punch holder + round bar 80 m/m in diameter and the lower part consists of the die with the side wedges.

The above photo shows the punch holder mod. 40.05 and the punch mod. 40.09 of 80 m/m in diameter. By having a non-standard length of 205 m/m, the anchor locations had to be modified to join the two pieces.

These two pieces are manufactured with these anchors to facilitate their construction and at the same time facilitate the change in diameter for future work, as it is extremely easy to use another diameter and utilise the existing punch holder.

The above photo shows the special die and its two wedges, to facilitate the removal of the piece once it has been bent, because without these wedges, the piece would most likely get stuck there, with the consequent effort made by the operator and the economic loss caused by spending too much non-productive time.

FINAL PIECE

As can be seen in the following photograph, the 10 m/m thick and 100 m/m wide piece is perfectly bent to the angle requested by the customer.

THE MANUFACTURE

The tools are made of our standard C-50 steel, induction hardened in the working and grinding areas, so that the tool can be used regularly and without premature wear due to regular use.