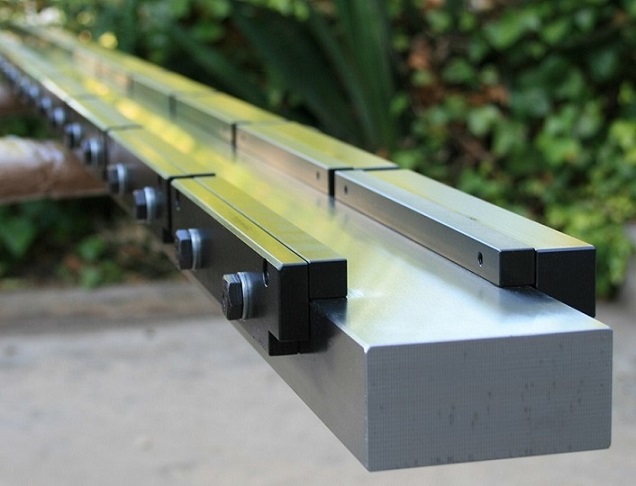

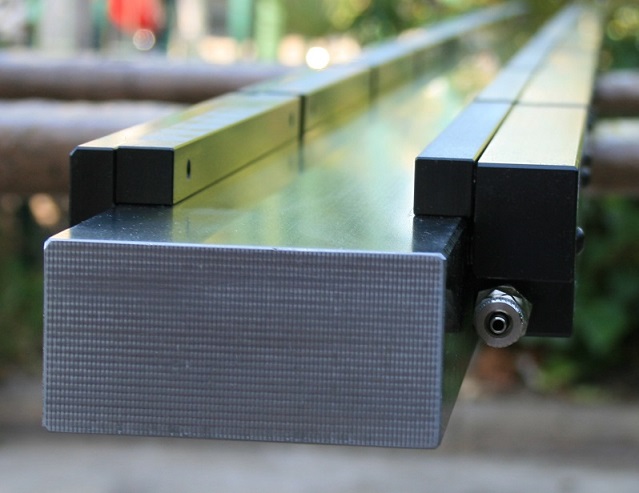

METALMAQ, S.A. delivered this month a die holder table of 3 meters, with pneumatic drive to couple dies type Promecam or European system and ready to install in a metal sheet press brake with free table.

THE HISTORY OF THE CHANGES IN THE PREPARATION OF THE PRESS BRAKE As we see day to day the preparation time of any metal sheet press brake is increasingly important and our customers seek to reduce those times to increase their productivity. In the times that run the series are usually short and what was previously usual to change tools in the press brake once a day, now it is normal to make between 5 and 10 changes a day, this considerably increases the downtime of preparation and thus It is time that you lose productivity.

THE DIFFERENT PUNCH TIE TYPES AVAILABLE The fast tie systems for press brake punches have been booming for a long time, from manual tie with quick manual tightening.

FAST TIE CLAMP

Or the pneumatic tie systems that still give more speed when making changes of punches;

QUICK PNEUMATIC TIE

WHY A QUICK CHANGE OF TOOLING? As we can see, the systems are several and increasingly abundant and this is due to the fact that the demand to lower preparation times increases, both in new press brakes, in used press brakes or in metal sheet press brakes already in use by our customers.

NEXT STEP; QUICK CHANGE OF PRESS BRAKE DIE The new pneumatic tie holder has been manufactured for a customer who is already a user of a quick pneumatic tie system and happy with its operation. Now he wanted to automate also the change of dies, but in his case having a multi-vee die installed in his press brake was advised to change the die to the Promecam system, which has more variety of dies and are also modular, therefore the time to manipulate and change the dies can be done by a single operator (reducing even more the preparation time). Another advantage of the supplied tie holder is that it is always centered in the press brake, avoiding moving it to align it when changing the die. This allows us that once centered (since the tie holder always remains fixed) and activating the pneumatic drive thereof, we open the flanges with great ease to introduce the dies of the press brake. Pressing the button again it closes the system and we are ready to work.