METALMAQ manufactures punches for LOIRE press brakes, specifically 3 punches of different configurations and in different lengths, for a well-known naval company in the south of Spain dedicated to the production of ships for different purposes.

THE CLIENT’S PROBLEM

It has ceased activity as a manufacturer of LOIRE press brakes, as the company was bought by GESTAMP and changed its machinery production. Consequently, clients do not know where to turn when they need to replace their press brake tools or manufacture different designs for other productions. Metalmaq has always been one of Loire’s reference suppliers and, as such, knows exactly the type of tools that need to be produced.

Throughout its long experience, Metalmaq has manufactured different types of clamping for Loire press brakes, as there are many variants of clamping for this brand of press brake on the market.

THE DESIGN OF THE PUNCHES

The client sent their designs from their Technical Office, which were very well detailed and had the following characteristics;

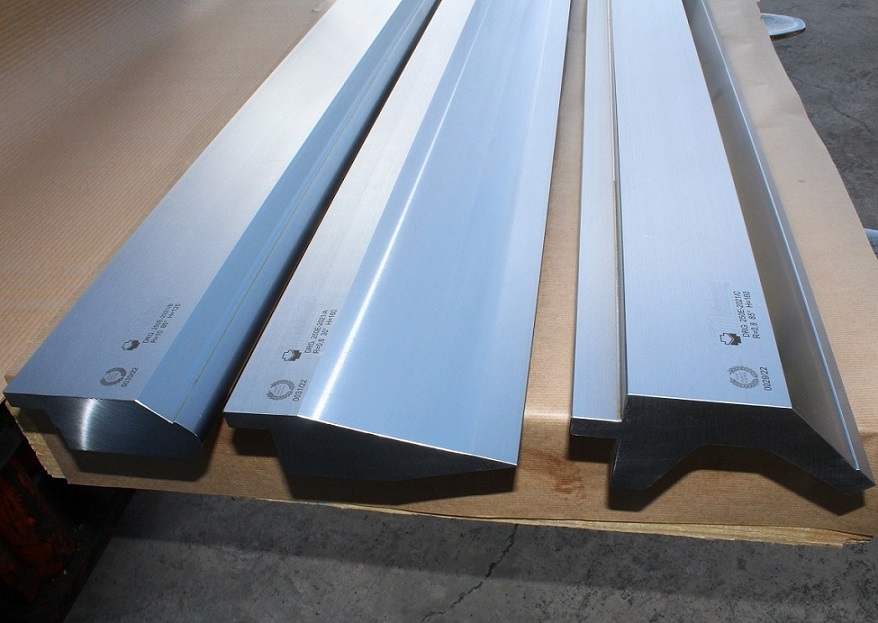

1st Punch

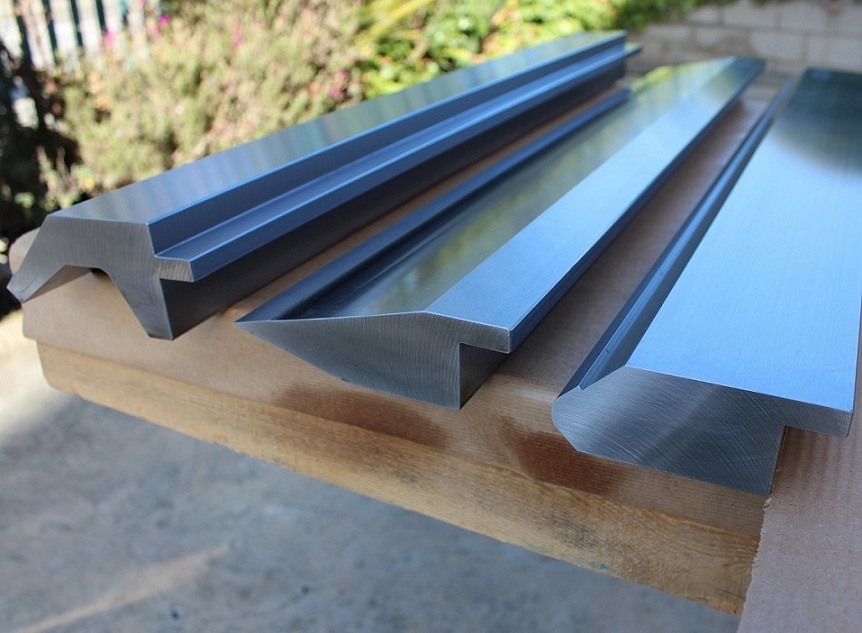

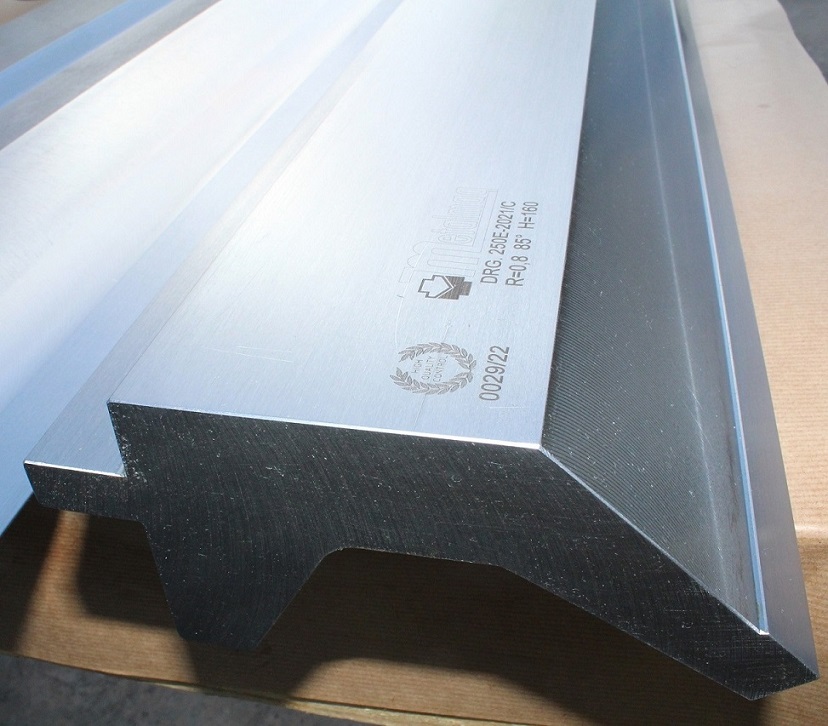

“Goat’s foot” type, at 85º, with H=160 m/m, 6 meters in length and divided into several sections according to the customer’s list.

This type of press brake punch is usually manufactured for customers who make fairly long “U” shapes and need a punch capable of holding the part to be bent without collisions, as the part is placed on the inside of the punch.

2nd Punch

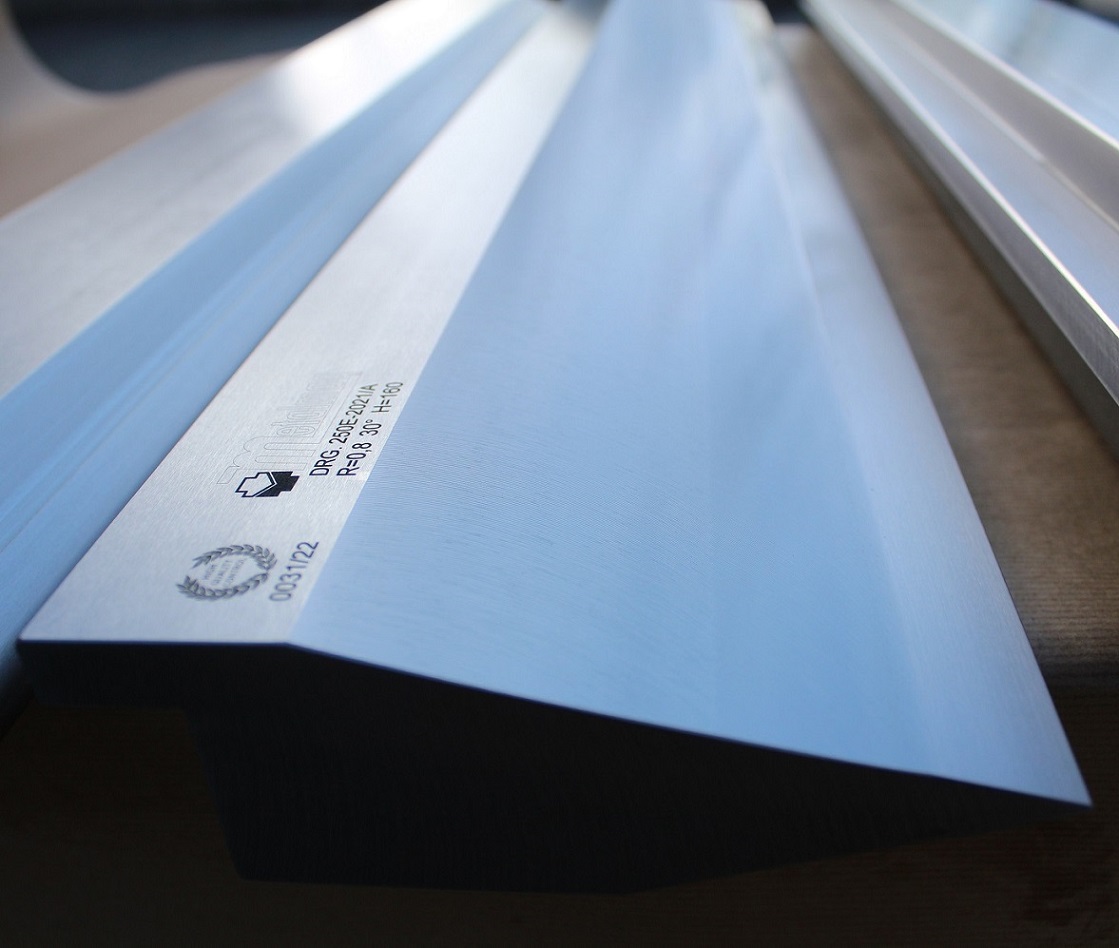

“Tip” type, at 30º, with H=160 m/m, 5.5 meters in length and divided into several sections according to the customer’s list.

“Tip” type, at 30º, with H=160 m/m, 5.5 meters in length and divided into several sections according to the customer’s list.

3rd Punch

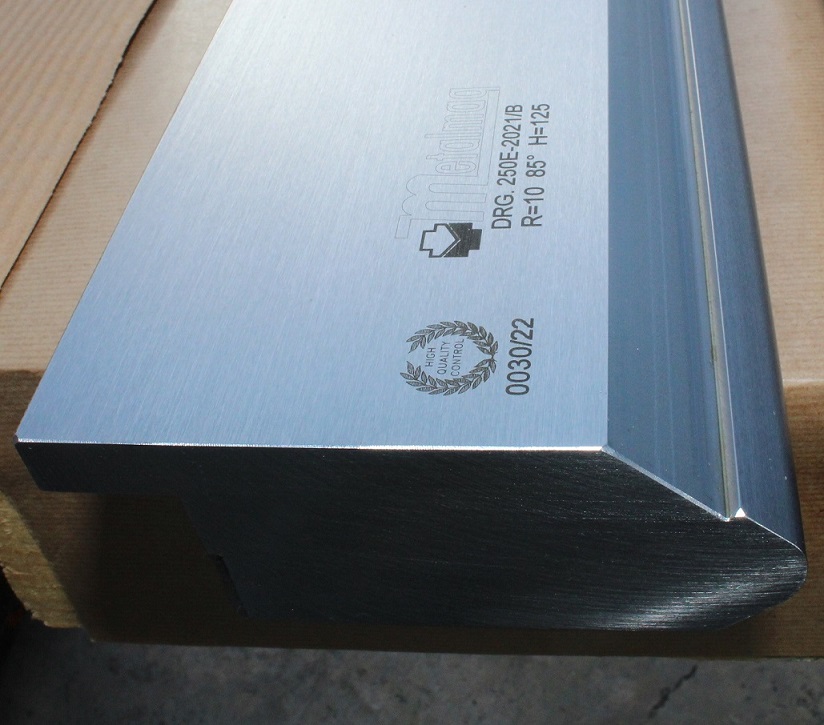

“Straight and robust” type, at 85°, with H=125 m/m, tip radius of 10 m/m, 4.5 meters in length and divided into several sections according to the customer’s list.

“Straight and robust” type, at 85°, with H=125 m/m, tip radius of 10 m/m, 4.5 meters in length and divided into several sections according to the customer’s list.

In the pictures above you can see the three types of punches manufactured and their different configurations.

MANUFACTURE

METALMAQ manufactures punches for LOIRE press brakes, in this case manufactured of hardened C-50 steel (with an approximate hardness of 60 HRC) in the working areas to avoid premature wear, thus prolonging their useful life, and finally they have been ground.

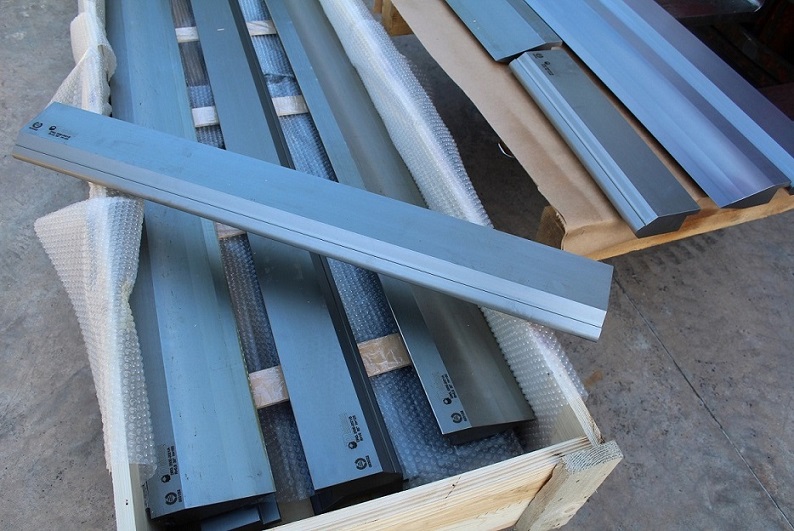

In the picture below you can see the entire batch of the different punches in the packaging process.