METALMAQ manufactures a punch with an inner window for a customer with a HACO press brake and with the clamping of the original punch of the same brand.

OUR CUSTOMER’S PROBLEM

The customer wanted to manufacture a “U” with 100 m/m outer “wings”, 65 m/m outer base and in 5 m/m thick sheet iron. The part to be bent has a length of 150 m/m and a large quantity has to be produced monthly.

DESIGN OF THE PUNCH

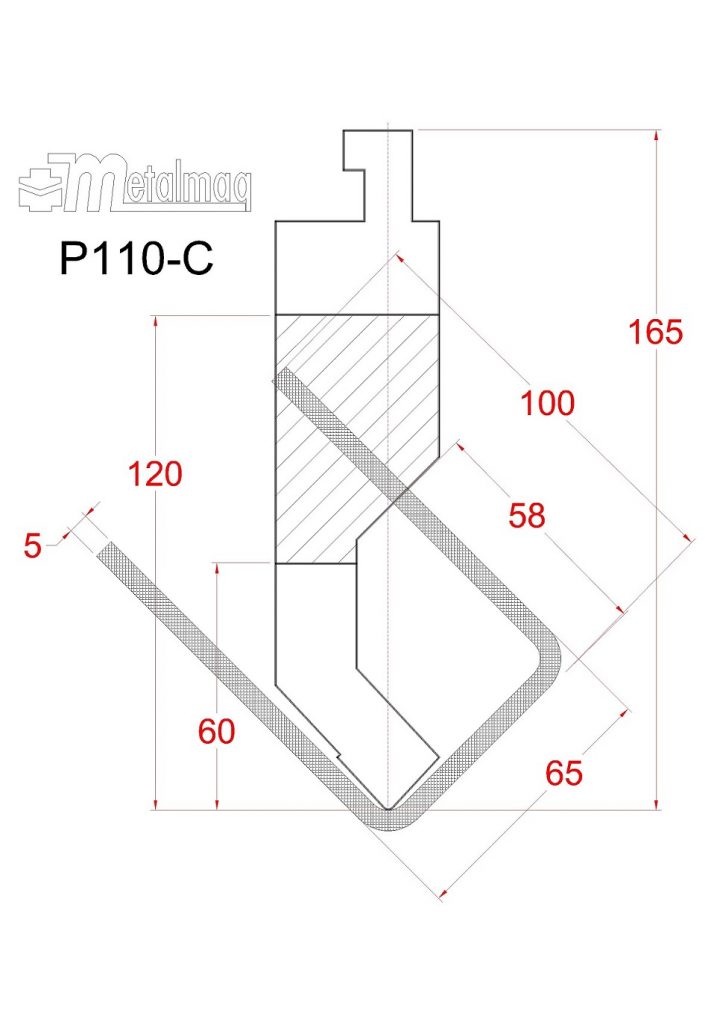

As mentioned above, the part only has a length of 150 m/m, therefore and with our experience in the vast “universe” of press brake tooling, the best thing to do is to make a window in a standard punch, in this case the HACO-CASANOVA model P110-C, as this way we do not have to make a very tall and large special punch to make the “U” that our customer needs. The original punch is manufactured in sections of 1,020 m/m and it was decided to make two halves of 510 m/m, leaving one as is for future work and modifying the other section to make said window.

The following sketch shows the “U” to be manufactured and how it moves inside the window. Therefore, the part is free of collisions and can be manufactured with a standard, but modified, punch.

THE SOLUTION

Punch mod. P110C is a standardised model of our production and we manufacture it in sections of 1,020 m/m. It has a height of 165 m/m and is very robust, just as it was manufactured in its original version. It is made of 42CrMo4 steel with a ground finish.

We are already one of the few press brake tooling manufacturers that continues to standardise this HACO-CASANOVA punch along with other models of the same clamping, to manufacture it and to keep it in STOCK for immediate delivery to any customer who needs it anywhere in the world. Since our true mission and satisfaction is to help our customers to simplify their work, offering quick, simple and the most cost-effective solutions possible, obviously ensuring the quality of all our products and the satisfaction of our customers.

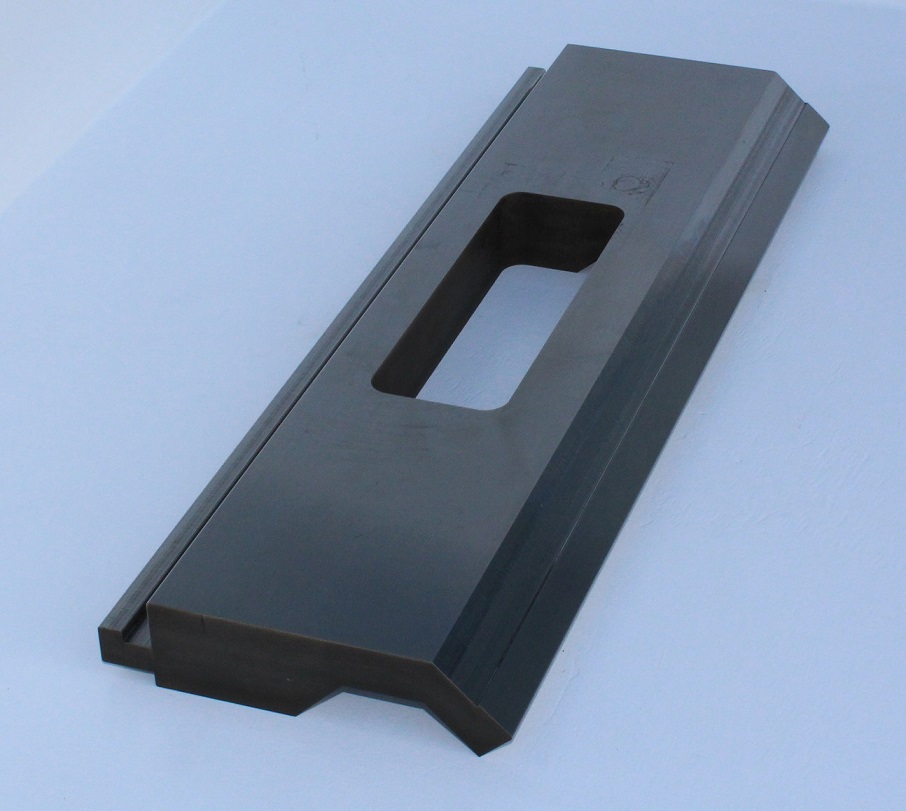

A plan view of the punch and the window manufactured by METALMAQ can be seen in the photograph below.

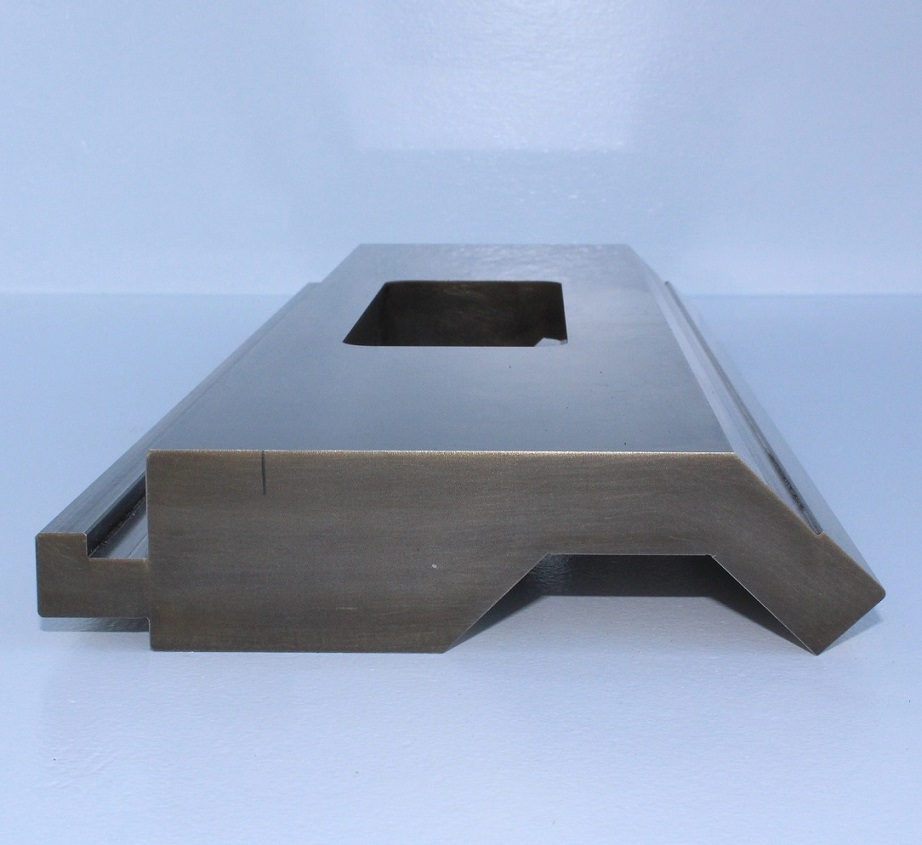

Front views of the modified punch can be seen in the photographs below.

THE CONCLUSION

The conclusion is that at METALMAQ, we are convinced that we know how to provide an optimal solution to all bending problems and in each case provide an appropriate solution, both with regard to the quantities of units to be manufactured and with regard to the geometry of the parts to be bent.