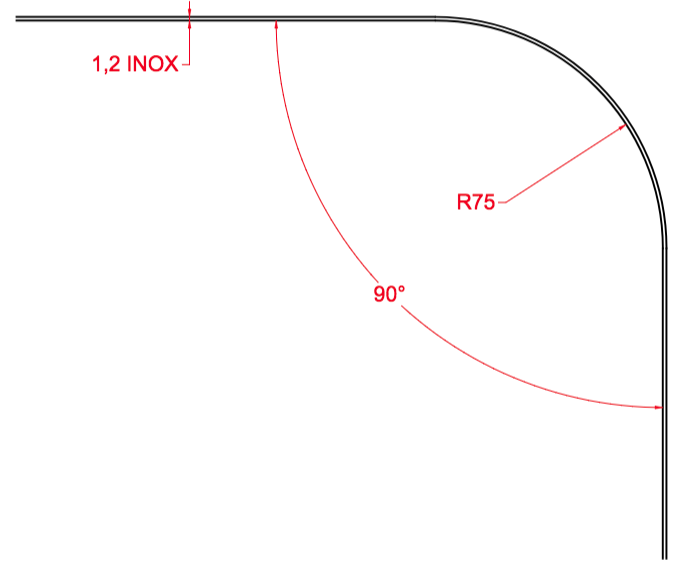

METALMAQ manufactures a special tool to make an internal radius of 75 m / m, in a sheet of thickness 1.2 m / m in stainless steel, on request.

Requirements

- Perform internal radius of 75 m / m with Trumpf press brake and Wila mooring

- Do not mark or scratch the piece during the bending operation, as it is a sawn part

Solution adopted by Metalmaq

Once the customer’s requirements were studied and after doing several tests with metal sheet that the same customer supplied us, we decided to make a smaller radius than the one marked on the sheet, since after the folding operation the material gives way and the radius increases. We must bear in mind that in a normal folding operation, at 90 ° for example, the fibers of the material are broken and the material remains immobilized after the bending operation. However, when a deformation is made and the fibers of the material are not broken, as it is the case of large radius, the sheet tends to open a lot (about 10 or 20 degrees depending on the type of sheet and radius measurements). This causes that the radius grow when the sheet tries to go to its original position, therefore, calculations and tests must be done to determine the radius measurement of the punch to be manufactured.

Fabrication of the tool to bend large radius

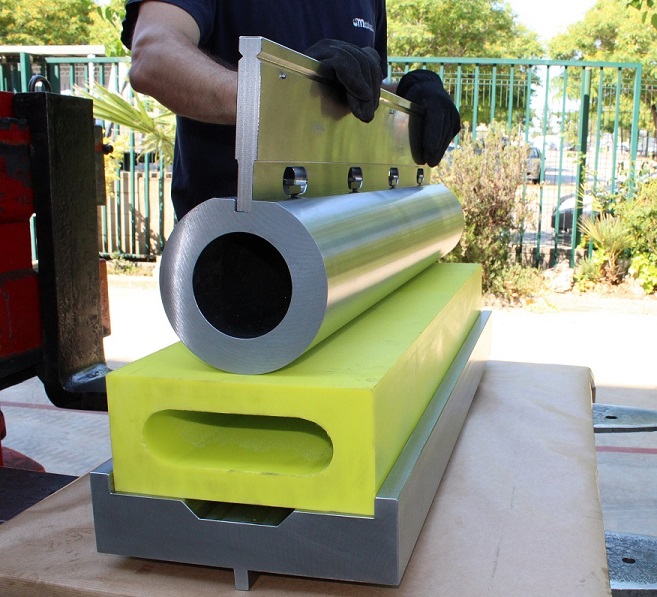

Once our technical team studied the requirements and needs, we produced a special tool to make an internal radius of 75 m / m, in a sheet of thickness 1.2 m / m in stainless steel. The punch was made hollow to reduce its weight and it was adapted in a standard punch holder with Wila mooring , giving the customer the possibility of installing the round in another folder with different mooring, simply changing the punch holder model or placing a new round for another occasion. As a die, an Adiprene Block of special production was used and installed in a special die holder to improve its performance and manufactured with Wila mooring.

Absence of folding marks on the sheet

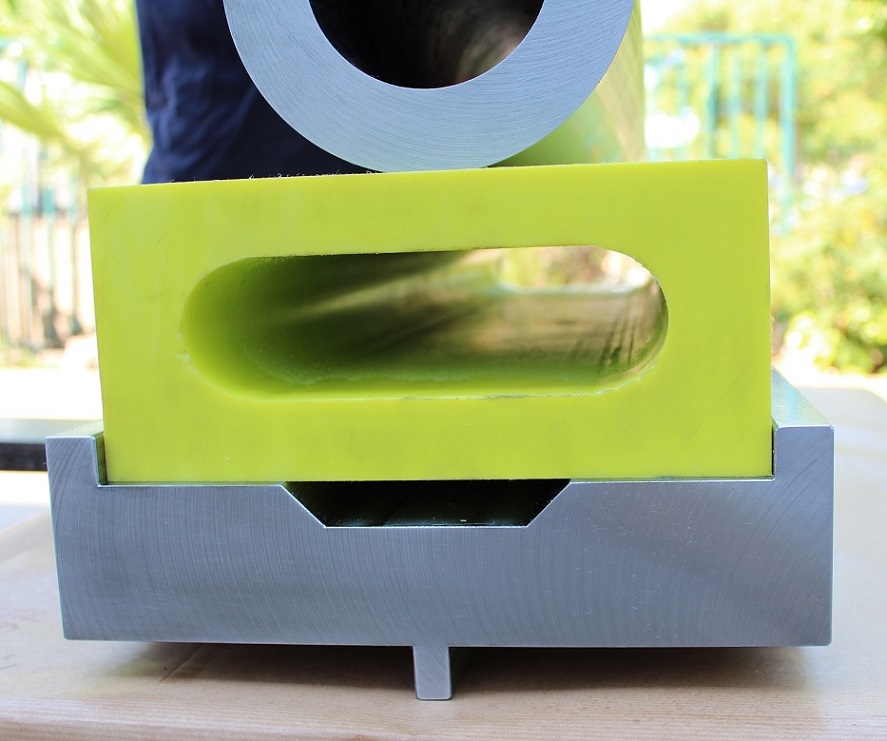

The Adiprene Block has been made hollow in the central part so that it matches better the radius of the piece.

The great advantage of using this system is that the block of adiprene adapts to the radius of the punch and if we change the radius for another piece, the part of the die should not be changed.

With this system the sheet is not marked, since the friction in the folding operation is on the protective film, which avoids scratches and unwanted marks.