Special round drawing tool is the last special tool manufactured by METALMAQ, delivered to a customer who manufactures structures for industrial buildings and located in the north of France.

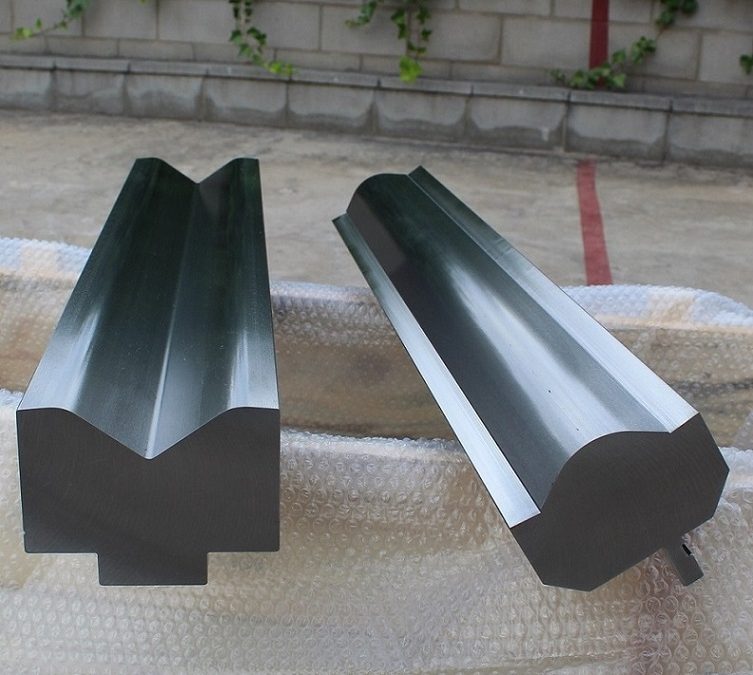

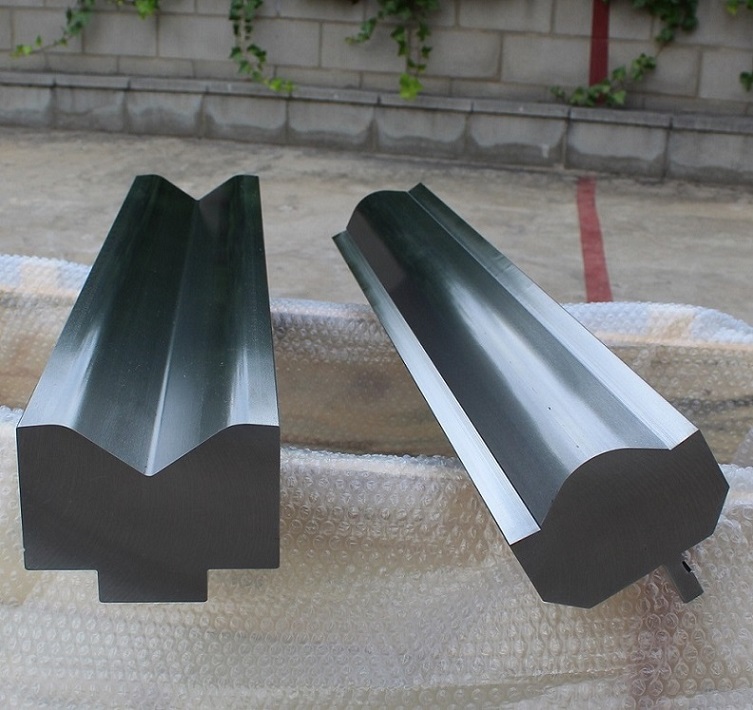

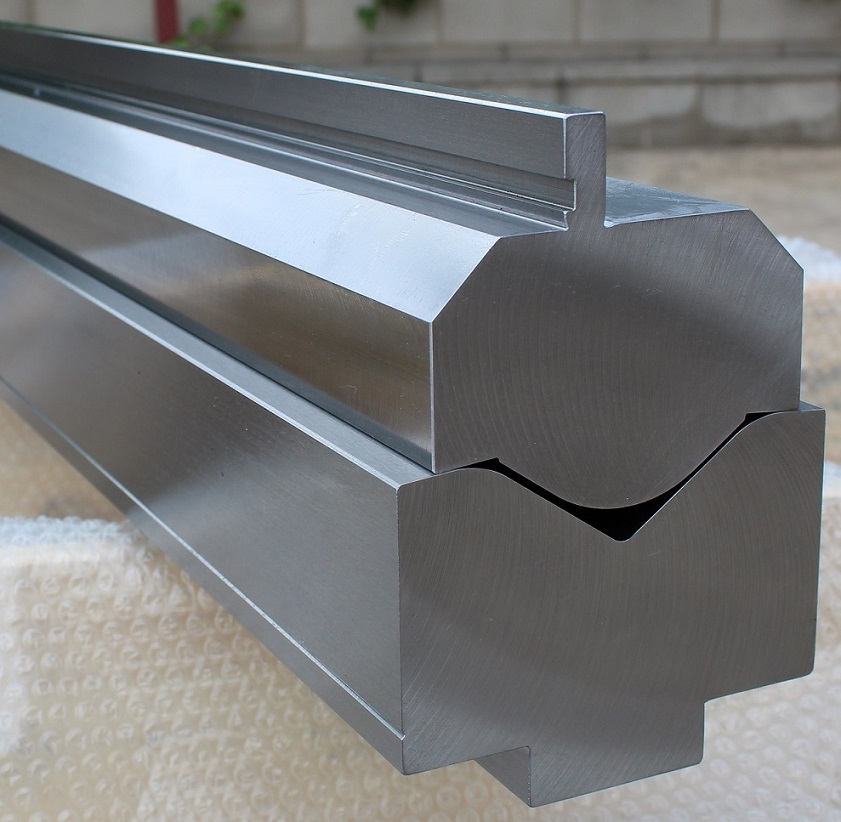

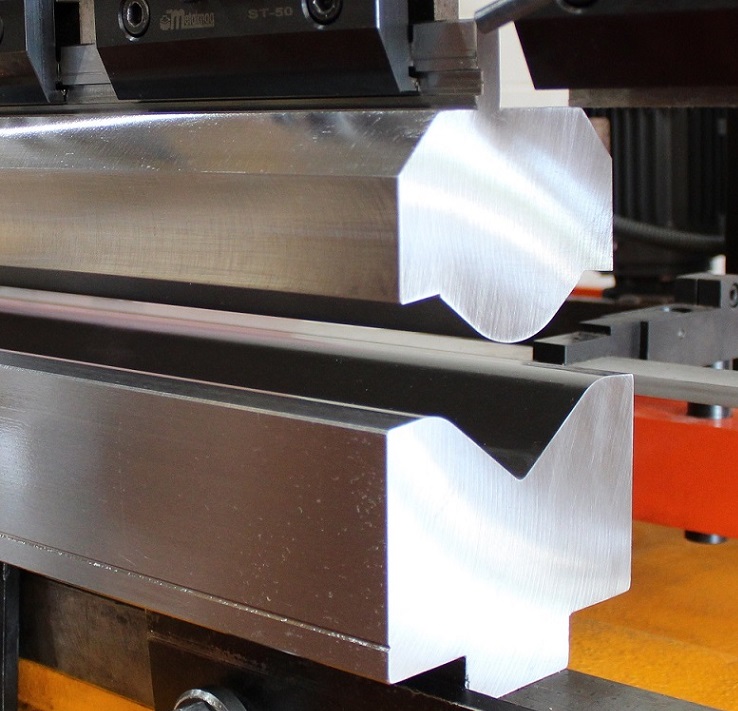

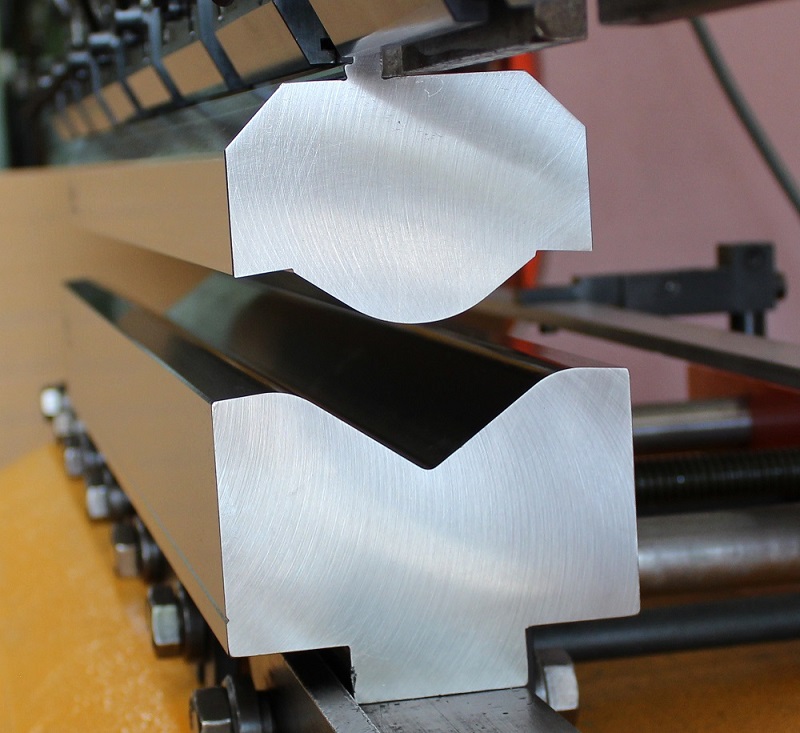

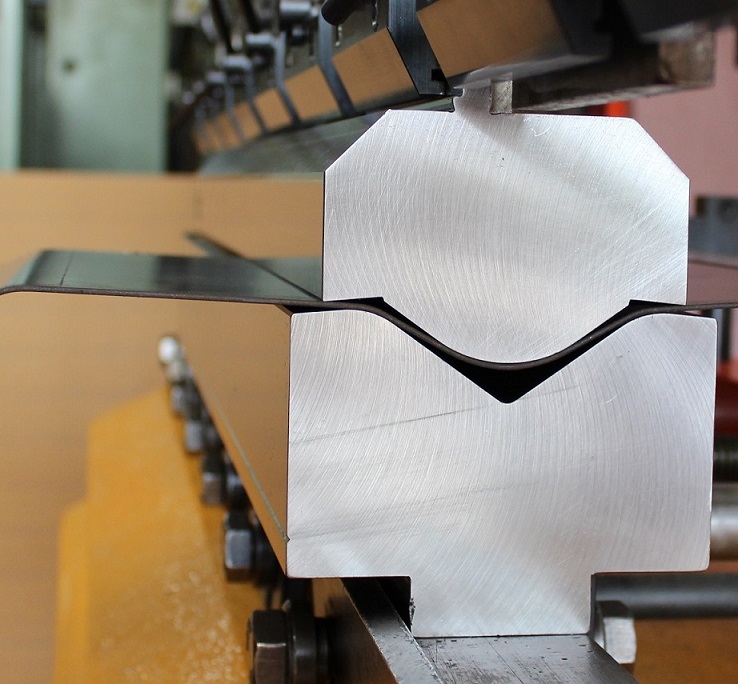

In the photos above you can see a set of the special tool, just as it was being fitted together to be sent to its final destination. In the central part of the tool you can see the large radius shape that our customer wanted, and you can also see on the sides the inclination of the walls.

This is done to compensate the bending point, so that, once the sheet is bent, it is completely flat, even if the same sheet is stamped several times in a row.

CUSTOMER DEMAND

Our customer had to make a 3-bend stamping at a time, but with the characteristic that the central part had to have a very large radius for aesthetic reasons and for the design of the metal structures for industrial buildings, which is the main activity the customer has been involved in for 40 years.

The customer has an ERMAKSAN press brake with 200 tons and measuring 3 metres in length, with Promecam clamping (also known as European system). The part had to have a total length of 2,500 m/m, therefore, 3 sections of 835 m/m of the special tool were manufactured.

It should be noted that in order to stamp this part in 2 m/m iron sheet, 60 tons per metre are needed. Since the part is 2.5 m long, 150 tons are needed in total, and since the customer’s press brake has 200 tons, stamping can be done effortlessly in their press brake.

THE SOLUTION

We have a lot of experience and many years of experience in tools of this type, but we always make a small prototype with samples of our customer’s sheet metal to define the stresses and possible deformations that the sheet metal undergoes in the bending operation and that we must take into account when manufacturing the final special tool.

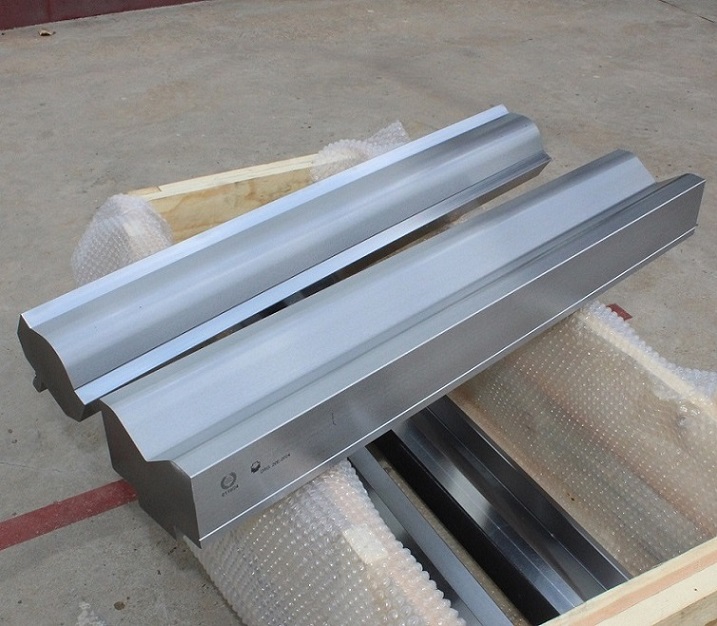

After the relevant tests, we manufacture the special tool, which will be produced in C-50 steel, with the working areas induction hardened (reaching hardnesses of 58 HRC, thus avoiding premature wear due to friction and extending the life of the tool) and ground.

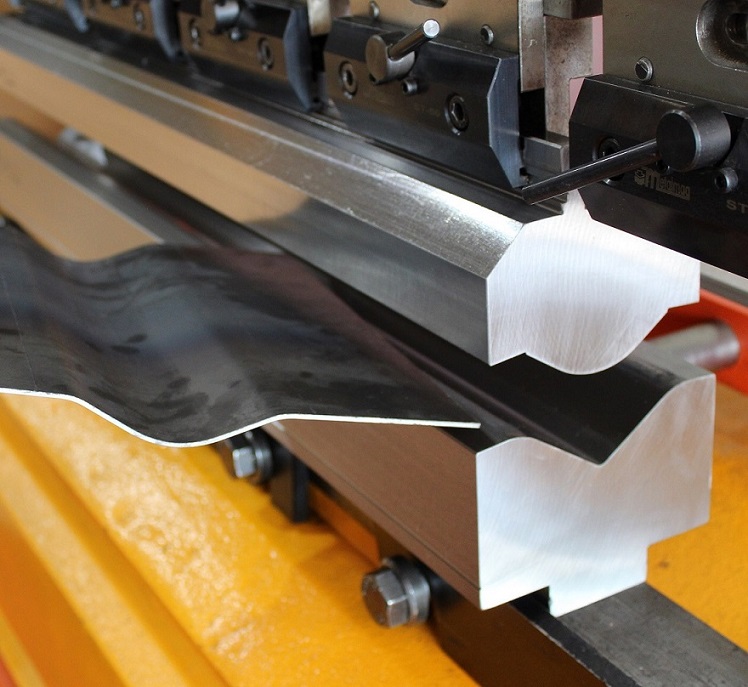

In the pictures above you can see the tool mounted on our MEBUSA press brake to carry out the final tests with the 2 m/m iron sheet sent to us by the customer.

RESULT

The parts resulting from the tests were flawless and as you can see in the photos below, the part is well shaped and flat, being able to perform stamping several times in a row without losing the flatness of the sheet.

The best way to see how the special tool works is in the following video, where you can see a perfect stamping, as it is repeated with the sheet always flat.