METALMAQ sells in Estonia, its latest special tooling order for a customer with a high-performance TRUMPF press brake.

OUR CUSTOMER’S PROBLEM

The customer has a TRUMPF press brake with a high tonnage capacity and receives an order to bend S355 steel (this steel is used to make structures and has excellent strength and weldability, making it very common in this type of work) with a thickness of 25 mm.

The unique feature of our customer’s work is that it must have an inner radius of 90 and must be bent at 103º, i.e. 13º more open than a 90º angle.

Manufacture of customised tools is one of our specialities, and it is very common for customers who have been using our tools for years to consult us about making a new product.

THE DESIGN OF THE PUNCH

The punch must be very strong (given the thickness of 25 mm) and must have a radius of 90 mm in order to be able to leave the sheet as the customer wishes.

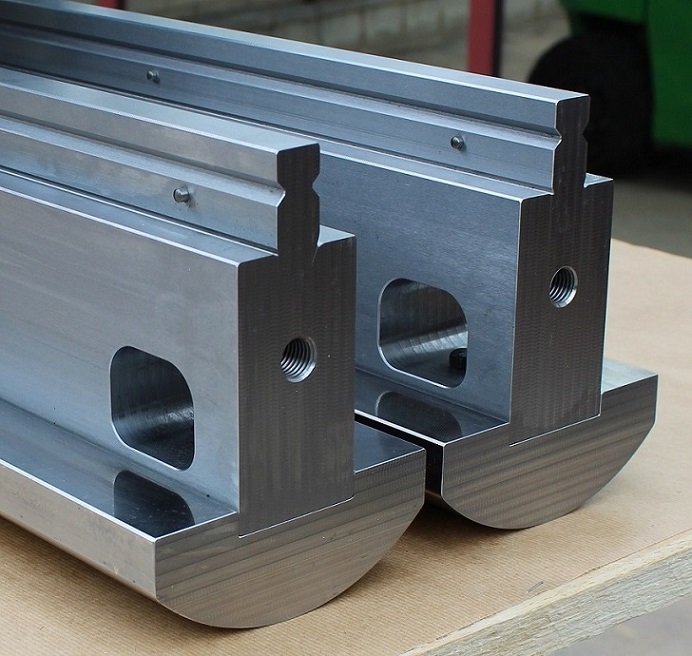

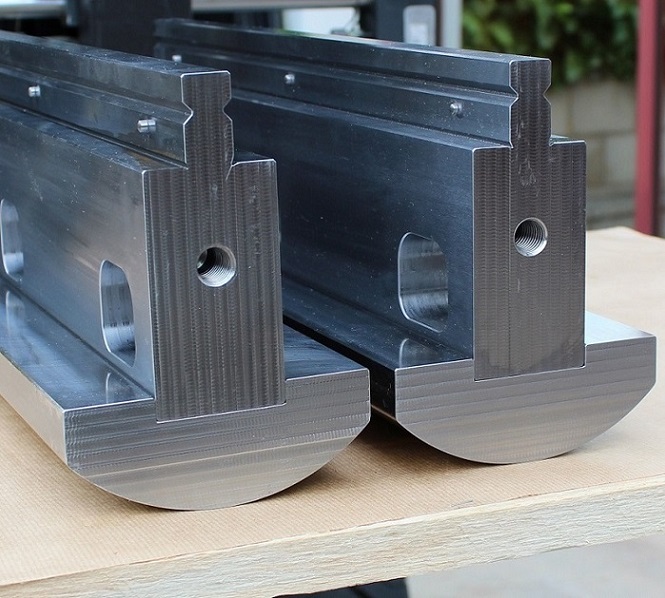

As can be seen in the first picture above, the punches are composed of a 90-radius punch and attached to it is the punch holder, which is anchored to the press brake and has a Trumpf clamp, also known as a Wila clamp (or what we call a SPEED clamp).

Second picture above shows M16 threaded holes on the side. This was not requested by the customer, but we usually make them in large and heavy punches and dies, in case they want to put threaded rings on them and handle them with a crane for greater ease and, above all, for greater safety for press brake operators.

THE DESIGN OF THE DIE

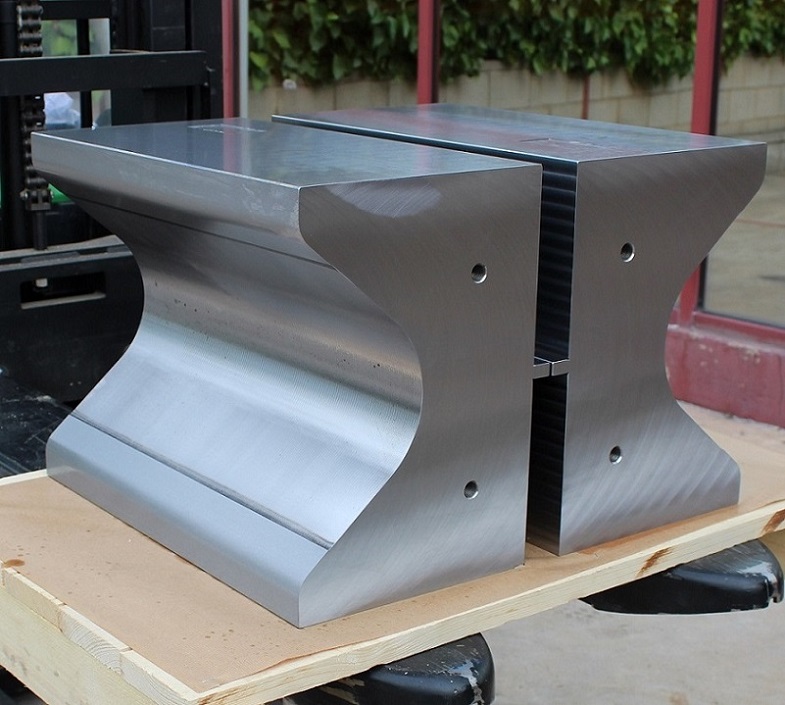

The die was designed with a 300 mm V-shape and an angle of 80º. It was sized to be large because S355 steel is somewhat harder than usual, so a good inner radius must be made. Therefore, it is always better to increase the V-shape so that the radius is well formed.

To define the standard calculations, we can refer to the BENDING TABLE (at the following link: https://metalmaq.shop/blog/en/metal-sheet-bending-tables/ ). This should always be consulted when bending any type of sheet metal to ensure that there will be no problems with breakage or misuse of the dies in our sheet metal bending machine.

The first picture above shows the two 300 mm V-shaped dies and their large dimensions (each 500 mm section weighs about 500 kg). The picture also shows that on the sides we have made two M16 threaded holes. This is done to be able to insert a threaded hook into them and move the dies more easily and safely for press brake operators.

Second picture above shows a detail of the plates in the dies. Here, apart from our logo, you can read the reference of the die and most importantly a number. This number is an internal record where we can see the traceability of the die, the steel used, and all the details of its manufacture. This is very useful in case the customer wants to replace or expand the dies in the future and ensure that the whole process is correct.

MANUFACTURE

Both the die and the punch are made of 42CrMo4 steel, induction hardened in the working areas to prevent wear and thus extend the service life of the tools, and finally ground.