METALMAQ its after-sales service made it possible to modify a standard punch so that our customer could manufacture parts in just over a week.

OUR CUSTOMER’S PROBLEMS

Our customer is located in Valencia (Spain) and had to manufacture U-shaped iron parts with a 61 mm base, a 160 mm flange and a 5 mm thickness.

The company received a large order for these parts, with a length of 100 mm long and with the problem that they had to be delivered very quickly and, therefore, we could not manufacture a special punch.

THE SOLUTION

As we mentioned earlier, the part that the customer had to make was only 100 mm long, and with the experience we have in the world of press brake tooling, the best thing to do is to make a window in a standard punch, so that we can speed up the execution time and deliver it in less than a week.

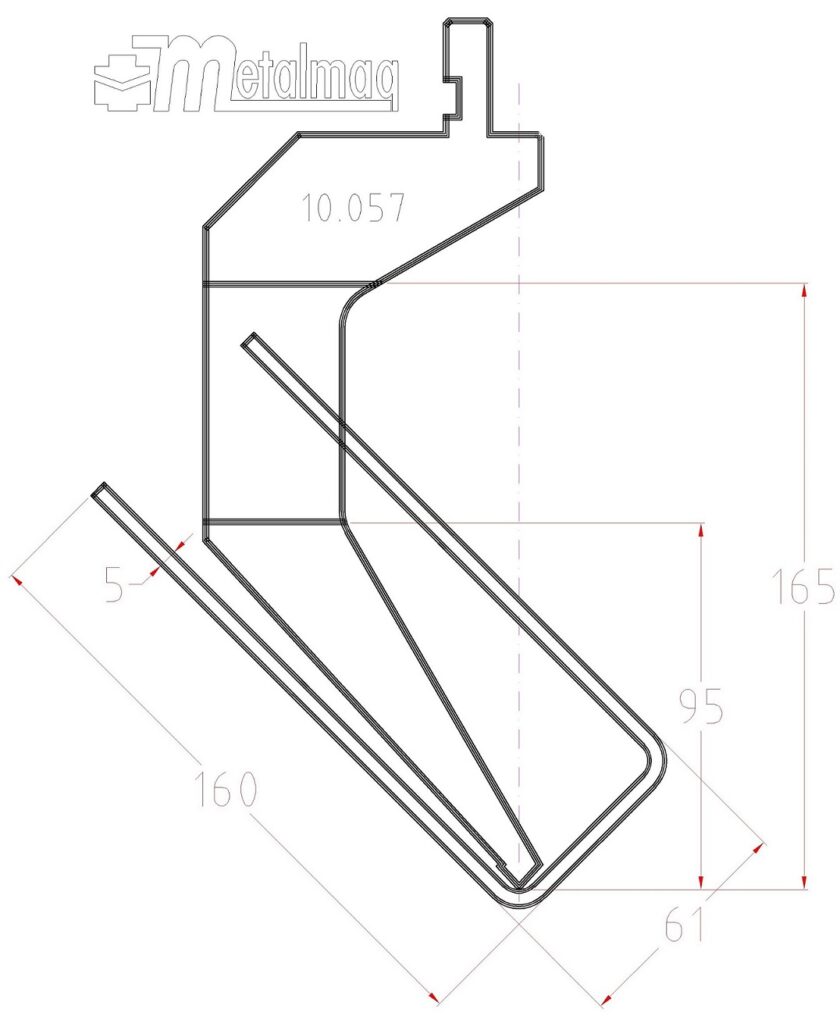

In this case, the model chosen was the 10.057, with Promecam-European clamping, which is the highest standard punch we make, with a height of 200 mm + clamping, i.e. a total height of 230 mm.

The customer has an ADIRA press brake, measuring 135 tonnes and 3 metres in length, compatible with the Promecam clamping or European system.

The standard punch mode 10057 is manufactured in a standard length of 505 mm. It has this length because it weighs 34 kg and if it were longer, the press brake operator would no longer be able to handle it safely.

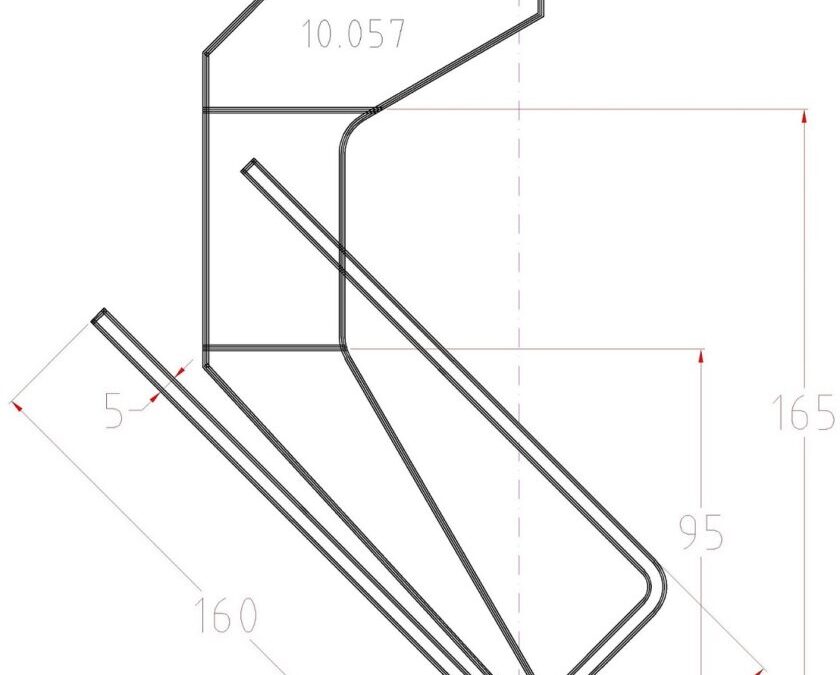

The following sketch shows the U-shaped part to be made from a 5 mm sheet and how it looks on the punch. The two stripes in the centre of the punch (dimension 95 and 165 mm) are where the inner window will be made.

OUR AFTER-SALES SERVICE

At METALMAQ we always want to give our customers the best, and our after-sales service allows us to help provide fast, reliable and cost-effective solutions.

Our after-sales service is made up of grinding machines, milling machines, drills, wire erosion machines, laser marking machines, etc.

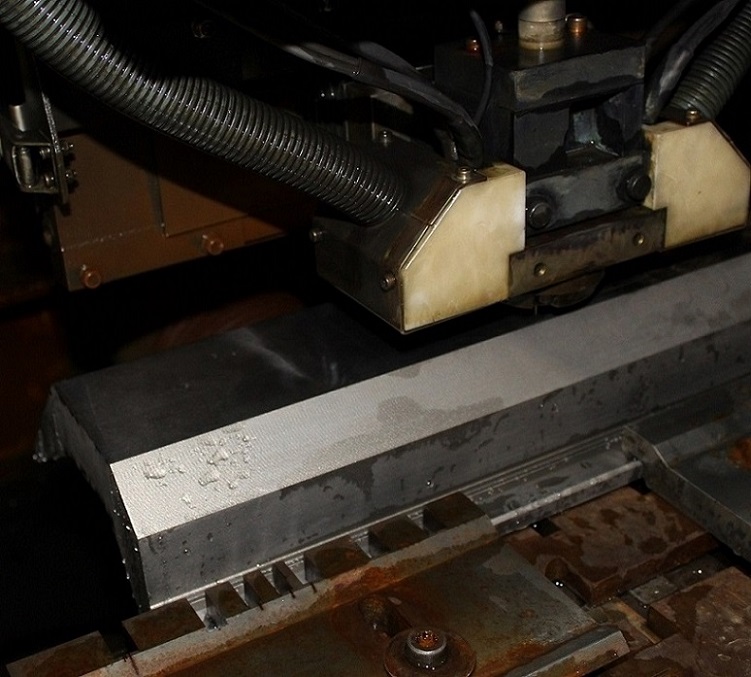

One of the machines we have in our after-sales service is an EDM machine and with it we have made the window for the punch.

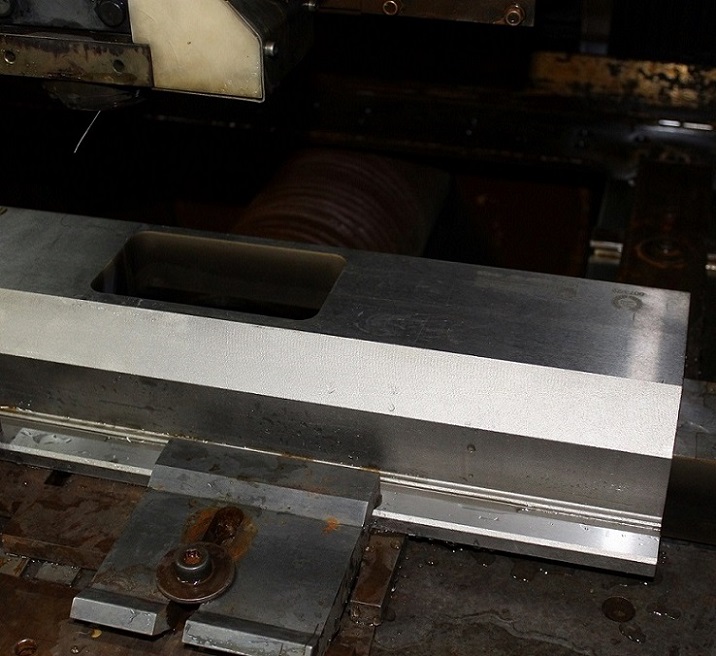

The pictures above show the punch inside the EDM machine once the work is finished.

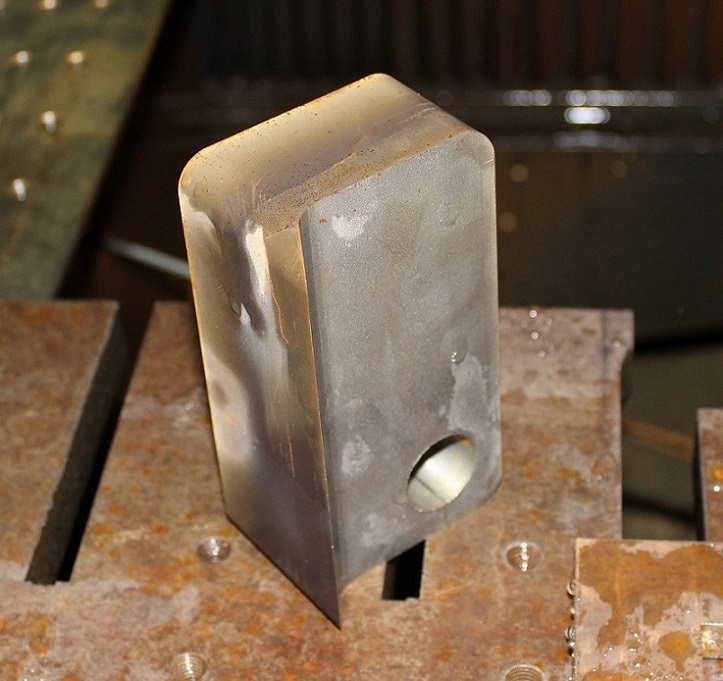

As a curiosity, the picture below shows the piece of material (the inside of the window) that came out of the punch. You can see the dimension of the work done and the great thickness of steel that was extracted.

THE CONCLUSION

At METALMAQ we demonstrate every day that we know how to provide an optimum solution to all bending problems and in each case give an appropriate response. Above all, we emphasise our execution speed.

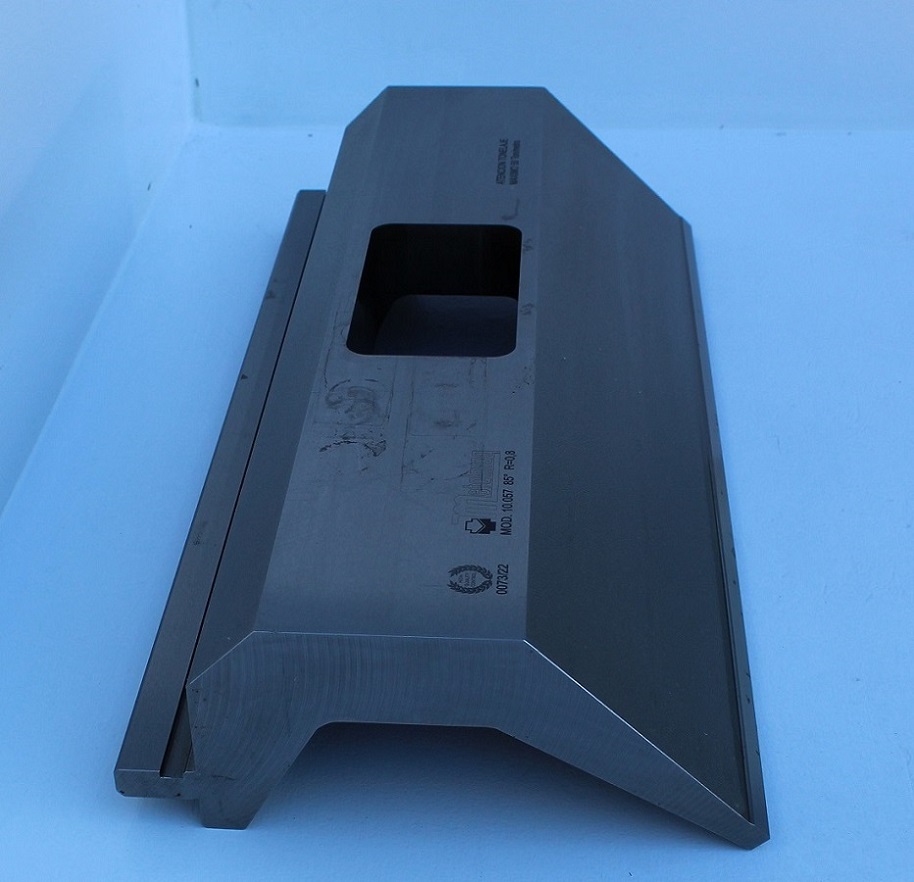

The pictures below show the finished work of “opening” a window in a standard punch.

The second picture also shows the warning mark on the right side made with our laser, which reads; “ATENCIÓN TONELAJE MÁXIMO 50 Ton/metro” (ATTENTION MAXIMUM TONNAGE 50 Ton/metre). We usually mark with a laser the maximum tonnage recommended in all the punches that we modify, thereby ensuring that the press brake operator can see it and be warned that the tonnage has been reduced in the punch due to its modification. This prevents possible accidents and breakages.