2025 a good year for METALMAQ, is our summary for the year that we have ended with a good turnover and with some projects that we are working on.

A SUMMARY

Press brake tools

Our year has been marked, as it could not be otherwise, by the production and sale of press brake tools for all brands of sheet press brakes. At present, these typically account for more than 70% of our turnover.

The year 2025 has been the first full year of sales and distribution of the 4 models of multi V-shaped dies that we have manufactured in collaboration with one of the best Chinese manufacturers of press brake tools, and it has been a sales success.

The 4 models of the new cos-effective series of multi V-shaped dies are the following;

COST-EFFECTIVE DIE 1319

This is the smallest die in the range, with a 54 x 54 square and with 7 V shapes, from 6 to 32 mm at 88º, and with 2 V shapes of 6 and 12 mm at 30º.

COST-EFFECTIVE DIE 1318

This is the medium-sized die and one of the best sellers, with a 74 x 74 square and with 8 V shapes, of 8 to 45 mm at 85º, and with 1 V shape of 12 mm at 30º.

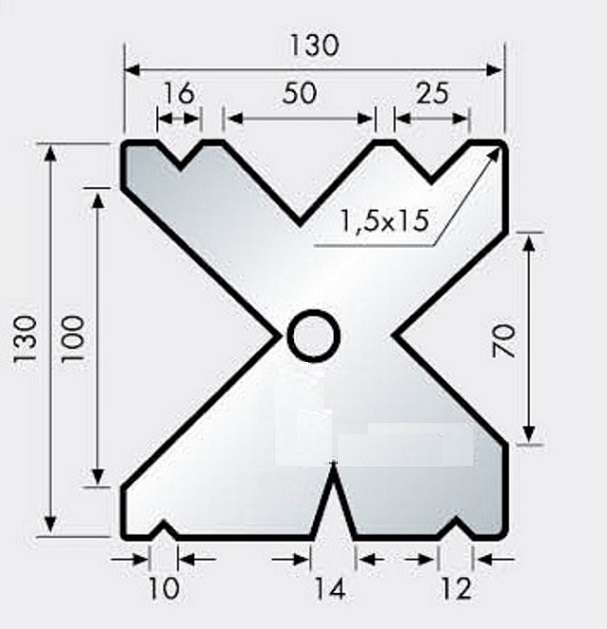

COST-EFFECTIVE DIE 20.10.626

This is larger than the previous one, with a 90 x 90 square and with 6 V shapes of 10 to 70 mm at 85º, and with 1 V shape of 14 mm at 35º.

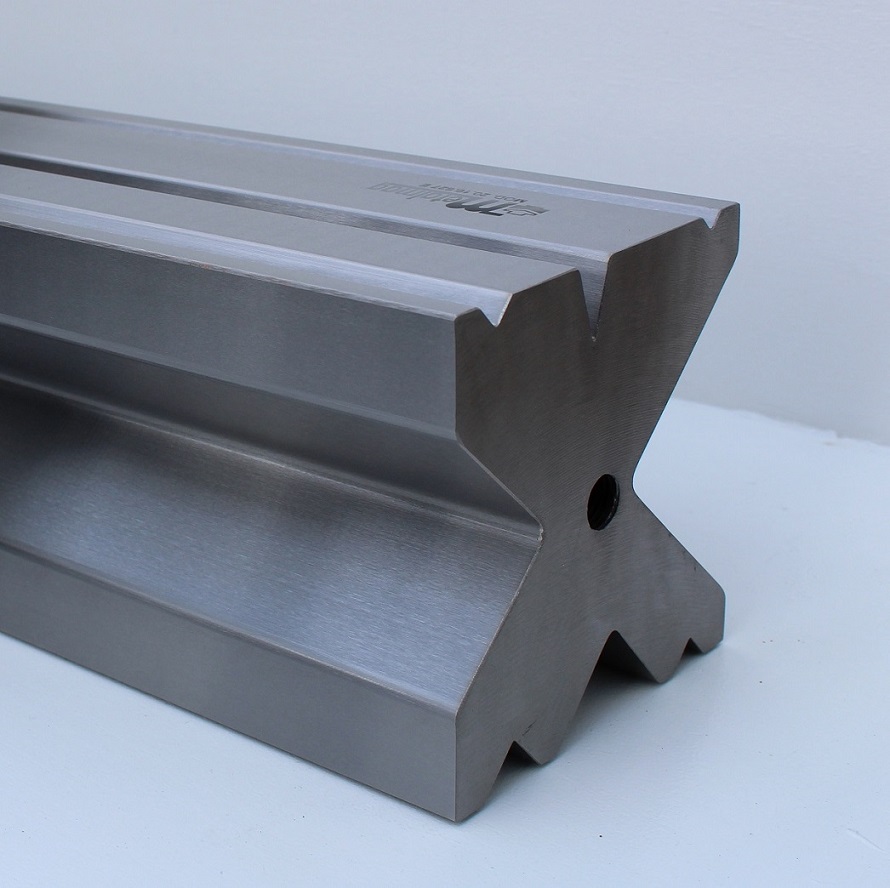

COST-EFFECTIVE DIE 20.10.627

This is a large-sized die, with a 130 x 130 square and with 8 V shapes of 10 to 100 mm at 85º, and with 1 V shape of 14 mm at 35º.

All four models are made of 42CrMo4 steel, induction hardened in the working areas (hardness 52-58 HRC) and ground.

Press brake accessories

30% of our production consists of press brake accessories, of which we manufacture many models, to help make sheet metal bending faster, safer and more comfortable for users.

Our products range from manual flanges, such as the ST-41 and ST-43 of the Promecam system, and AJIAL 120×40, 99×60 and 200×60 flanges, to the ST-44, ST-50 and ST-100 quick clamp flanges of the Promecam system, as well as the ST-70 quick clamp flanges of the AJIAL-COLLY system.

The other most important accessories that we manufacture are;

– Protective rubbers to avoid marking the parts during the bending operation. With our three models; USA Rubber, 0.4 Polyurethane Rubber and 0.8 Polyurethane Rubber.

– Supports to optimally hold the protective rubbers: P/60 SUPPORT and P/112 SUPPORT.

– Two types of Laser Line to better show the bending line of the sheets: the DIE’S LASER LINE PLUS and the i-LASER LINE, the latter with three accessories for optimal coupling to the press brake.

– PNEUMATIC HAMMER to separate the laser-cut parts

– LASER SLAG CLEANER 1020 and LASER SLAG CLEANER 2300. These two machines clean the slag adhered to the laser blades (also called fakir beds), giving an optimal result in the laser cutting operation, as the quality of the parts increases when these blades are in perfect condition.

– FRONT SQUARES: We manufacture several types and the most successful are the RIGHT PLUS MAGNETIC SQUARE and the LEFT PLUS MAGNETIC SQUARE, ideal for making stops on parts that go with inclination and improving the daily work of our most professional press brakes.

– TEMPLATE: We are the only company that manufactures accessories of this type to go one step further in complicated parts to be bent that hardly have references or areas when making the stop. The most sold is the 120×120 MAGNETIC TEMPLATE due to its speed of use and practicality.

– REAR STOPS for press brakes, consisting of the REAR MANUAL STOP RPS-500/2 and the ELECTRIC REAR STOP RPS-500/MOTOR, which are essential for any press brake today.

And many more accessories that you can see in our section of PRESS BRAKE ACCESSORIES on our ONLINE SHOP, at https://metalmaq.shop/en/13-accessories-press-brake

THE CONCLUSION

We ended the year 2025 with a lot of effort and illusion and are starting 2026 with new projects that will be rolled out throughout this year…but that’s another story.