Special tool for enclosure, the last work of METALMAQ for a regular customer from Majorca (Balearic Islands-Spain), with a Trumpf sheet metal press brake and specialist in metal parts for quarries.

THE PROBLEM OF THE DIE

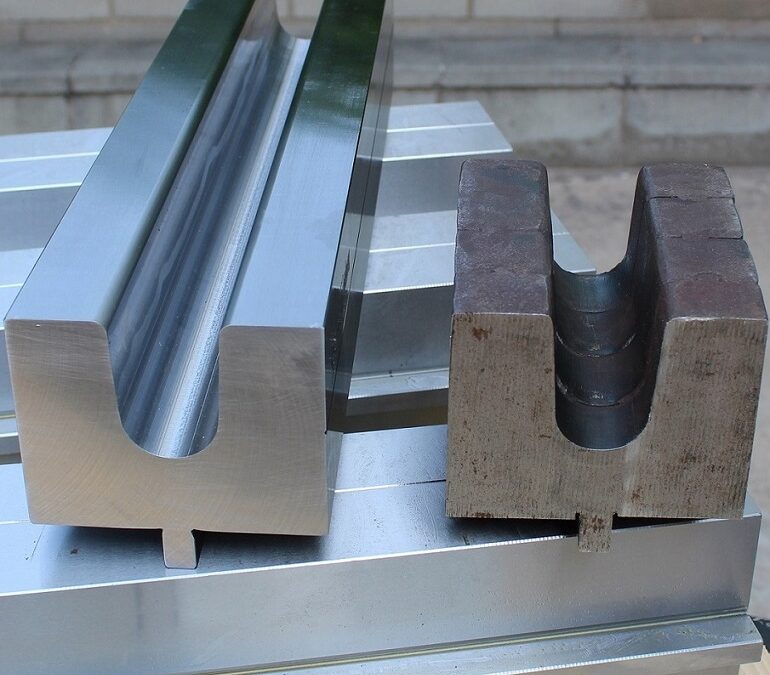

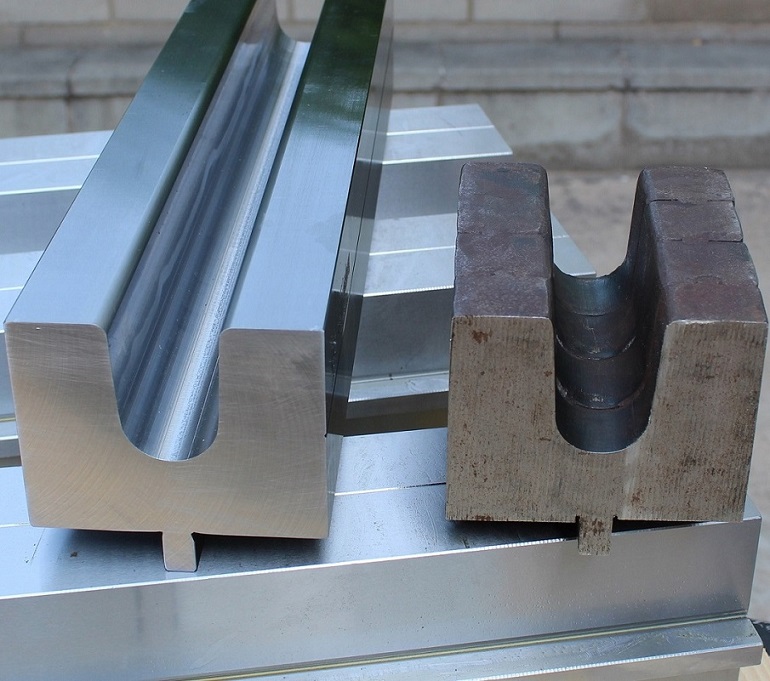

Our customer manufactures some parts to make thick sheet metal enclosures. They needed to do a regular quarrying job, and we advised them as to how they could do it. They accepted our proposal and, with their laser cutting machine, made some parts, welded them together, and manufactured a “homemade tool” in a 200 mm section to test how it worked and to see if our proposal had been useful.

The test went well, the customer was convinced and contacted us again so that we could manufacture four 515 mm sections. They also asked us to manufacture the punches for this job.

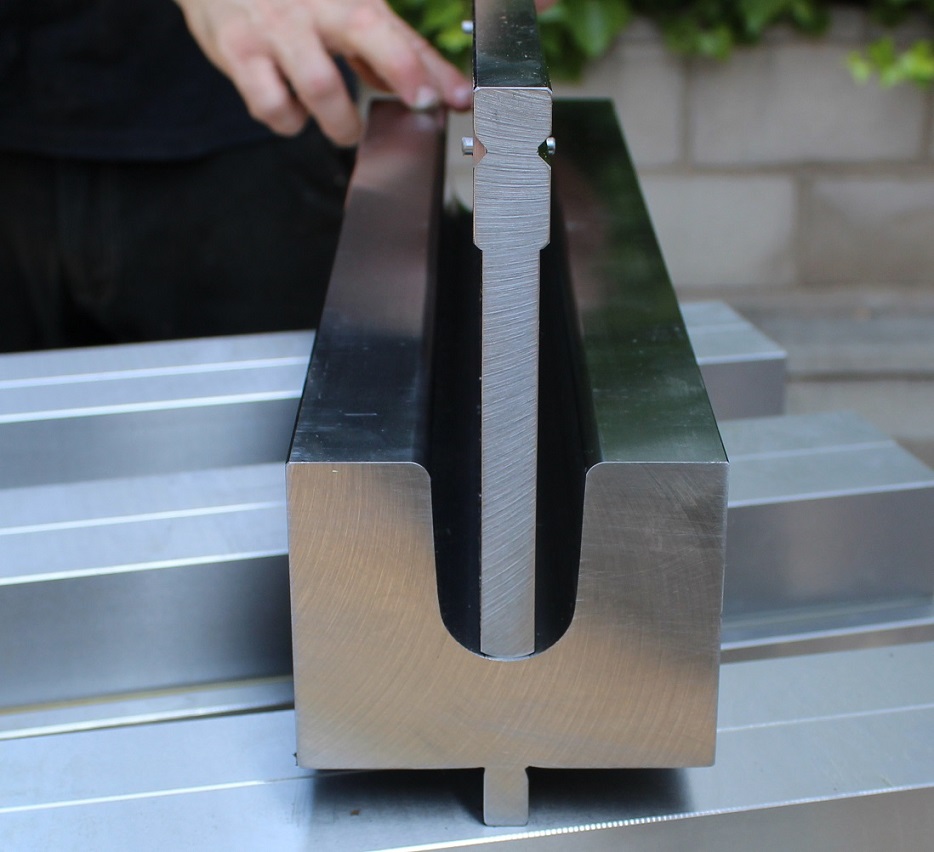

In the first photo above, you can see the tool made (homemade tool) by our customer to do the test, and in the second photo, you can see the four sections manufactured by METALMAQ. As always, they are manufactured with the quality that characterises us, induction hardened to guarantee their durability over time and ground, so that the four die sections are perfectly aligned.

You can also see in the photos above the lower clamp of the die (a 20 x 13 mm tail), which is the one used by TRUMPF press brakes to hydraulically clamp the dies in their press brakes.

You can also see the model below our logo, so that if the customer wants to extend the length in the future, they can quickly identify the reference and its design.

WE ALSO MANUFACTURE THE PUNCHES

Our customer also asked us to design the punches to match the dies in order to be able to do the job they wanted. We designed them, gave them the drawings for their approval, and started to manufacture them.

In the photo above, you can see the four punches we manufactured. You can see the typical Trumpf press brake clamp equipped with pins so that the punches can be placed laterally in the press brake and to be certain that they will not fall out, so as to ensure operator safety.

The case of the punches is exactly the same as with the special dies. Underneath our logo we marked the design of the special punch in case the customer wants to extend the length in the future and to be able to find it quickly.

MANUFACTURING

In the end, four dies and four punches were manufactured in 42CrMo4 steel, induction hardened, and ground, all using the specifications given to us by our customer, with their Trumpf press brake clamp, so that they could install it without any problem in it.

In the photos below, we wanted to show how the punch and the die work in order to be able to make the metal part that our customer asked for.