Special tool 30.10 is the latest special tool manufactured by METALMAQ, delivered to a customer who manufactures facades and roofs of industrial buildings and is located in northern Spain.

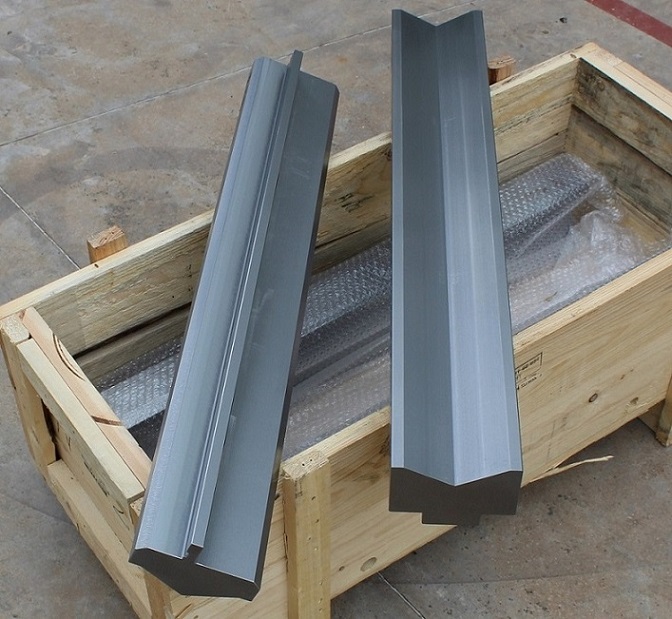

The photos above show the set of the special tool manufactured, right at the time it was being packed to be sent to our customer.

THE CUSTOMER’S REQUEST

Our client wanted to perform stamping with three bends in a single operation, as this part is manufactured in large quantities and is currently done in three separate strokes, requiring the sheet to be turned over, which is slow and dangerous for operators. And since the three bends are repeated along the entire length, the part becomes increasingly laborious.

Special tool 30.10 . Our customer has a 200 tonne, 3 metre long MEBUSA press brake equipped with a Promecam (or European) clamping system. The customer’s part had to have a total length of 2,500 mm, therefore 3 835 mm sections of the special tool were manufactured. The customer wanted it in sections to facilitate the work of assembling and disassembling in the press brake, as well as to be able to do it with a little more comfort and safety for workers.

The part to be manufactured is made of 2 mm thick aluminium. Customer’s press brake weighs 200 tonnes in total and therefore has sufficient strength to be able to carry out drawing with a total guarantee over the entire length.

THE SOLUTION

Although we have more than 40 years of experience, we always make a small prototype with samples of the sheet that our customer sends us in order to define the stresses and possible deformations in the bending operation that we must take into account when manufacturing the final special tool.

And even more so in this tool, as the sheet must be flat once bent, especially because in this particular case the bend must be repeated along the entire length of the sheet.

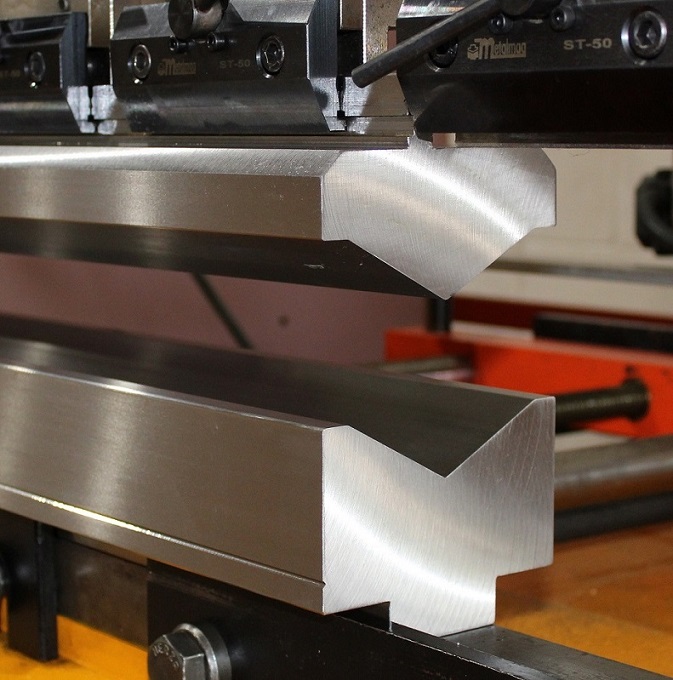

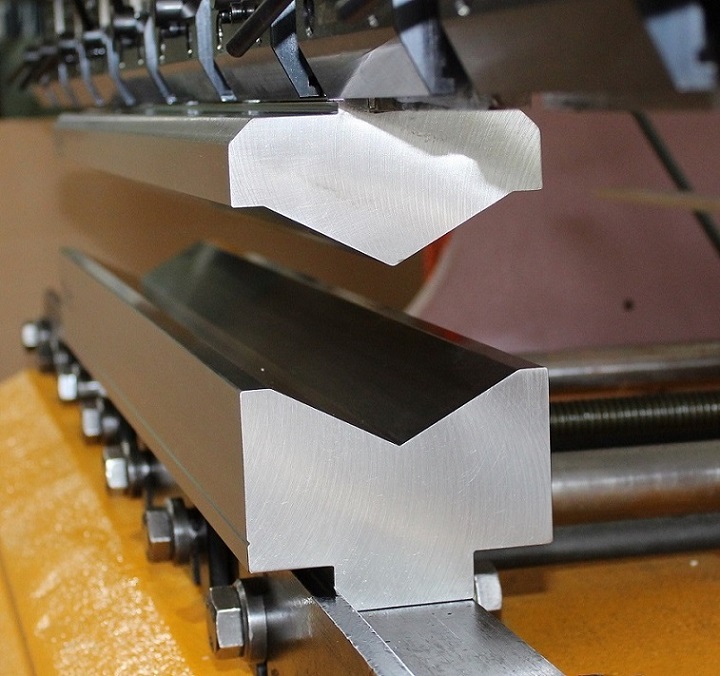

After the relevant tests, we manufacture the special tool, which will be made of C-50 steel, with the working areas induction hardened (reaching a hardness of 58 HRC, thus avoiding premature wear due to friction and extending the life of the tool) and ground.

The photos above show the tool mounted on our MEBUSA press brake. This last phase is carried out in order to verify that the tool is working correctly, so that the customer can have the total guarantee and security of operation as soon as he receives it, so that he can start producing parts immediately.

RESULT

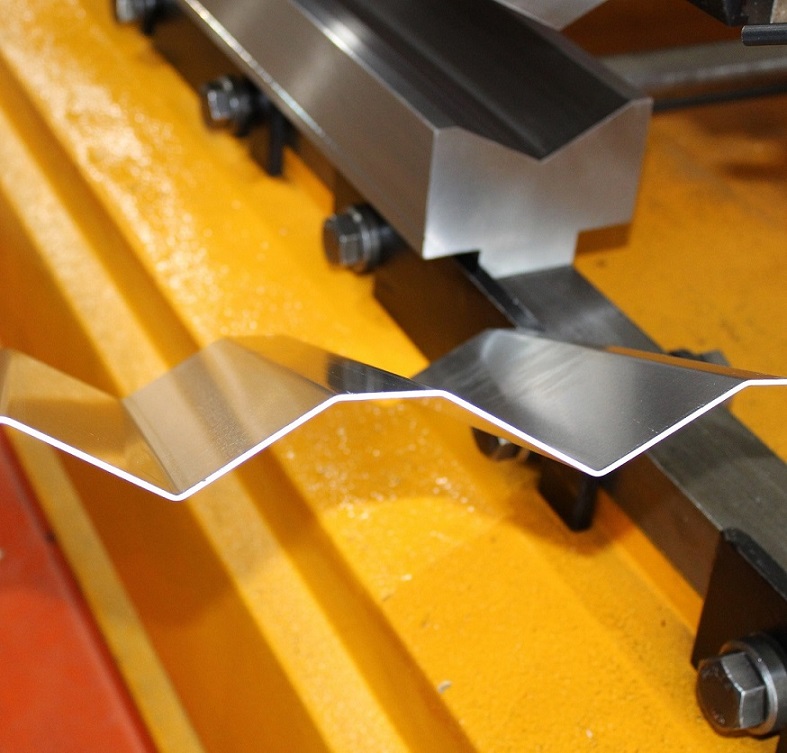

Once the tool was tested in our press brake, the parts came out perfectly. As can be seen in the photos below, the part is well shaped and flat, being able to perform several consecutive stamping operations without losing the flatness of the sheet.

The best way to see how the special tool works is in the following video, where you can see the perfect stamping and how it is repeated with the sheet always flat.