METALMAQ manufactures a special punch with a central window, for a press brake ERMAK of 3 meters, to make a “U” of large dimensions.

THE DIFFICULTY OF THE PIECE

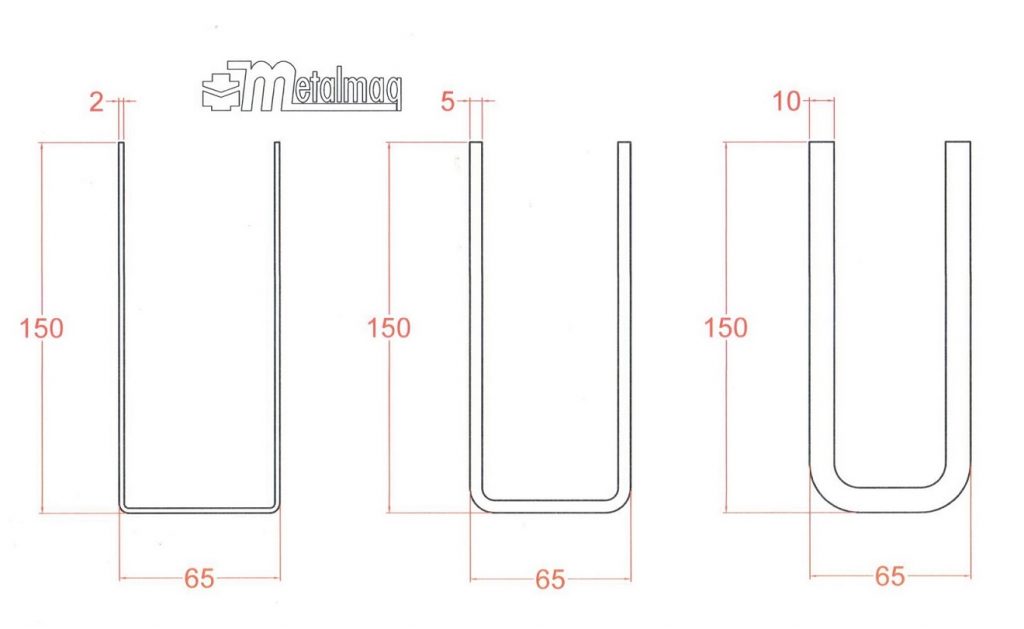

Our customer is a manufacturer of metal structures in the construction sector and must manufacture “U” with measures of 150 x 65 x 150 m/m and with thicknesses of 2 m/m, 5 m/m and 10 m/m thick, always in iron material.

These “U” are used for the fastening at curtain walls façades and similar structures, their maximum length is 150 m/m.

Being such a high “U” it can not be folded with standard tools, since the piece touches the punch when making the second bend, deforming the piece, therefore we have to ask the query to be able to bend them (in his metal sheet press brake ERMAK of 3 meters) in its different thicknesses.

The press brake ERMAK of our custoner is equipped with the Promecam tie system, both in the punches as well as in the dies (the system is also known as the European system, the Amada system or the Mebusa system).

SOLUTION ADOPTED BY METALMAQ

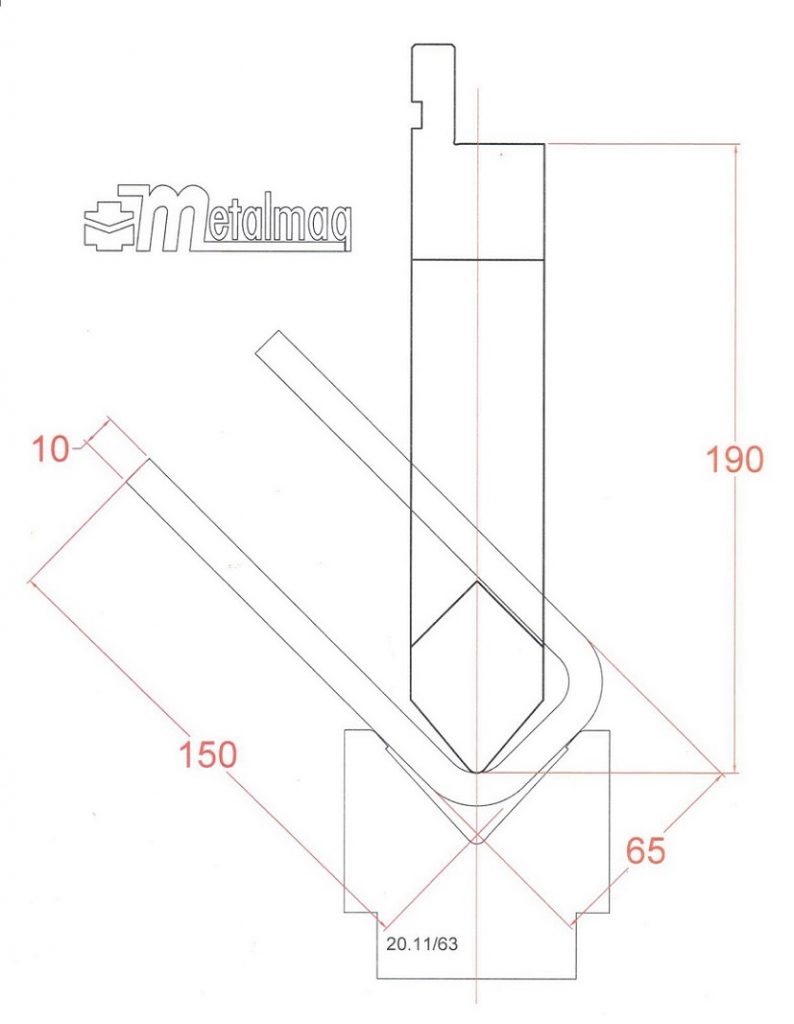

Our Technical Office designs a punch with an interior window, so that the piece once the second fold is made passes through the middle of the window, thus avoiding collision in it and the deformation that this would produce. Because the punch must also be bent up to 10 m/m metal sheet, it is manufactured with a large radius and with reinforced dimensions, to resist the pressure of the bend without major problems and thus prolong its useful life.

Due to the dimensions of the “U” to be made, the punch has a considerable height of 190 m/m + the punch tie, as can be seen in the attached sketch.

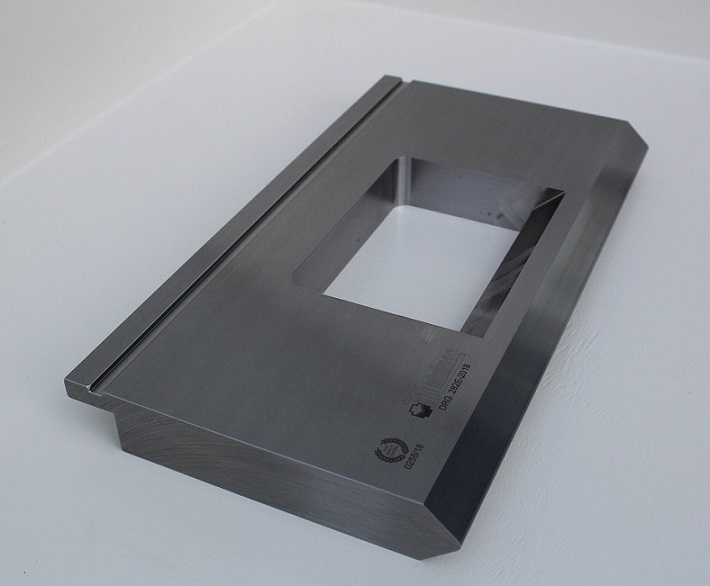

The special punch with inner window has been manufactured in steel 42CrMo4 tempered by induction in the work areas, with a large radius to avoid premature wear and with an interior window where the piece will pass in its last bend.

RESULT

The result, in view of the attached video, is a rather high punch, reinforced and with a central window so that the last bend is lodged in the press brake ERMAK of our customer. In the video there is a real demonstration with the piece of 2 m/m (in this case) that our customer has to do.

0 Comments