Manufacture of special intermediates is one of the last METALMAQ jobs in terms of press brake tooling that we have done.

THE PROBLEM

A customer contacted us and told us that he had a very old OMAG press brake with a non-standardised clamping of the punch, i.e. the clamping is different compared to the punches that are usually available on the market.

We have two solutions for these cases. We can either manufacture special punches with the shape that the customer wants and with its special clamping (which is usually very expensive, as it is made in a small series, and we also usually have delivery times of 8 weeks). Or we can make custom intermediates, with 150 mm sections, to convert your press brake with special clamping into a press brake with standardised clamping.

THE SOLUTION

The customer chose the option of making special intermediates and standardising their clamping.

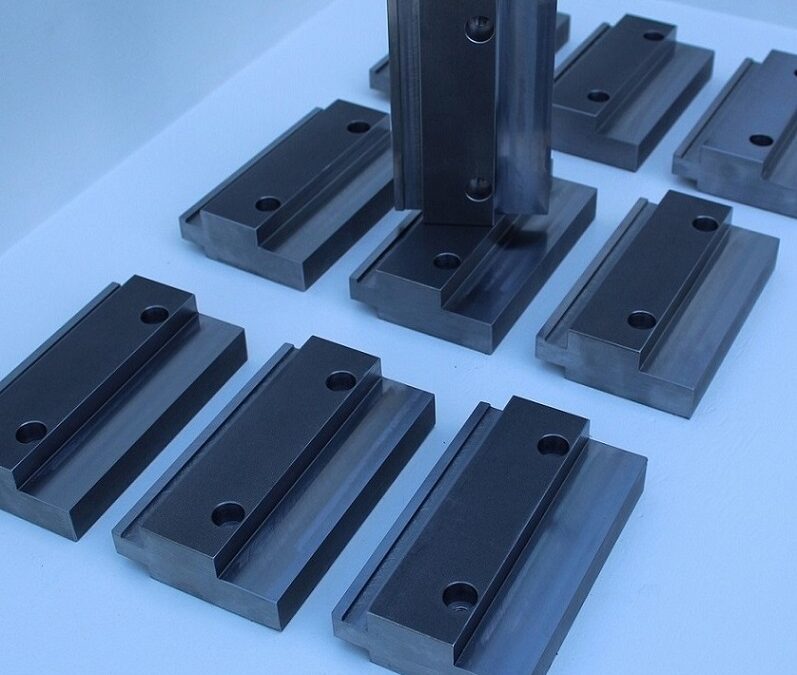

As can be seen in the picture above, 15 special intermediate units were manufactured, each being 150 mm long. Therefore, there is usually a distance of 55 to 60 mm between the intermediates. This distance is extremely advantageous, as it allows us to make “wings” of very high drawers, not only taking advantage of the height of the punch, but also adding this gap between the intermediates.

You can see another similar case shown in our BLOG at the following link: https://metalmaq.shop/blog/en/how-to-change-the-mooring-of-a-punch-and-a-special-die-of-a-press-brake/

The intermediates are supplied zinc-plated in silver colour to avoid their premature oxidation and to give them a very attractive appearance. As can also be seen in the pictures, the holes (where the clamps are fastened) are provided with a housing where the springs are located and so when the clamp is opened, it automatically separates from the intermediate, facilitating the work of changing the press brake punches.

WHICH PROMECAM CLAMPS CAN WE USE FOR ASSEMBLY?

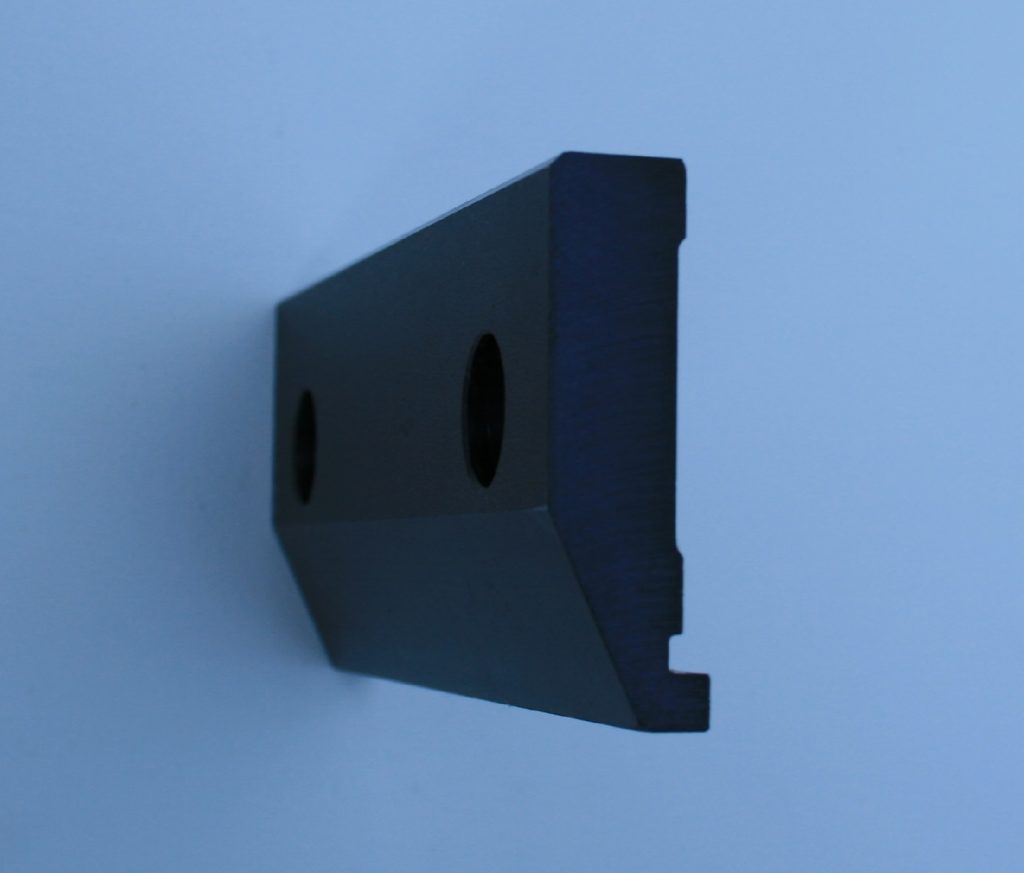

In the first picture you can see the intermediate without the clamp and in the second picture with the clamp already assembled. This clamp is used to hold the new punches with standardised Promecam clamping.

In this case the customer wanted to use the ST-43 clamp, which is equipped with screws for changing punches. Therefore these screws must be tightened and loosened with an Allen key to carry out the change operation.

Below we will explain the customer’s first option in this case, as well as the others they could have chosen.

ST-43 MANUAL CLAMP

The ST-43 manual clamp tightens the PROMECAM punches manually with 2 Allen screws.

ST-50 QUICK CLAMP

The ST-50 quick clamp tightens PROMECAM punches by means of an external handle. This makes it a very quick clamp in the operation of mounting and removing punches in the press brake.

ST-44 QUICK CLAMP

The ST-44 quick clamp tightens PROMECAM punches by means of a handle that is fully integrated in the clamp. This makes it very aesthetic and practical for the operation of mounting and removing punches in the press brake.