METALMAQ manufactures a special tool 30.06, to make a “U” in one fell swoop in iron sheet of 1,5 m/m and with an upper and lower mooring type Promecam (or European tool system).

THE PROBLEM OF THE PIECE

Our client is an industrial manufacturer in the electronics sector and had to assemble two pieces, one of 1,5 m/m iron and one of 3 m/m iron.

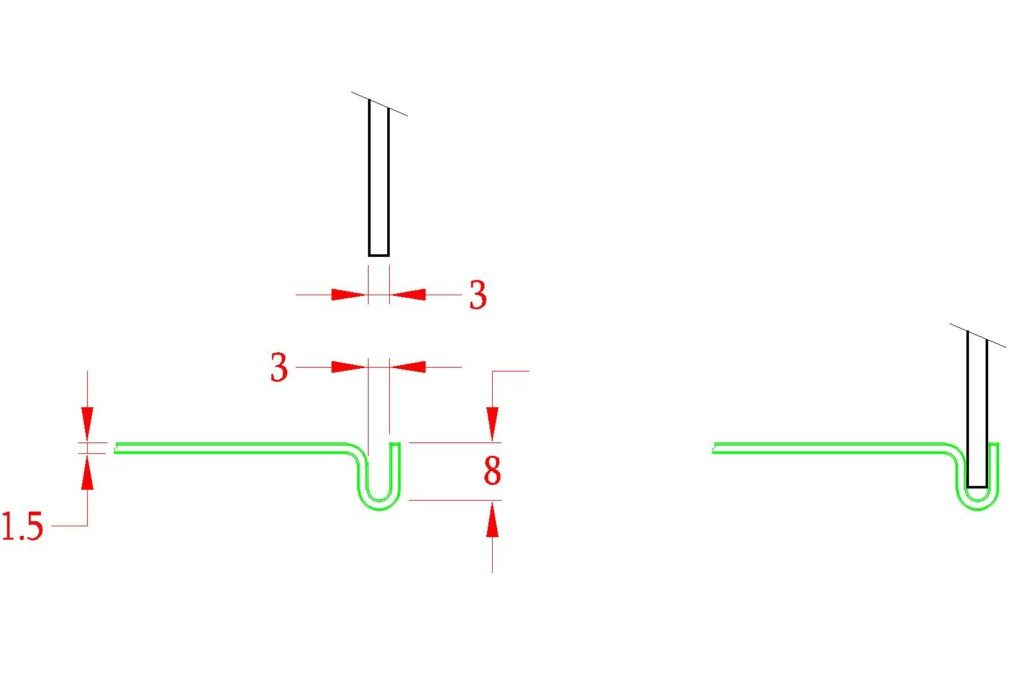

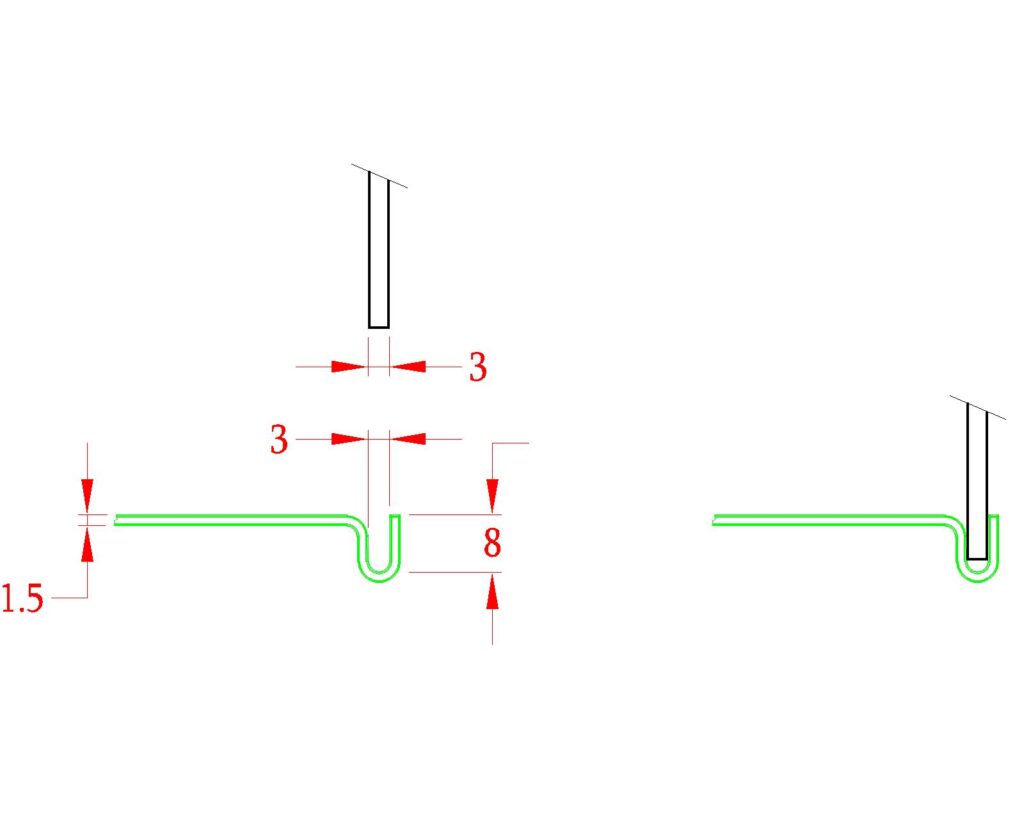

Together with our client we design the best way to make this type of piece. And in the end it was as you can see in the attached sketch

On the left side you can see the design of the 1,5 m/m iron piece (drawn in green) and in the upper part the 3 m/m sheet piece that must be fitted.

In the right part of the sketch you can see the two pieces as they fit perfectly.

THE SOLUTION

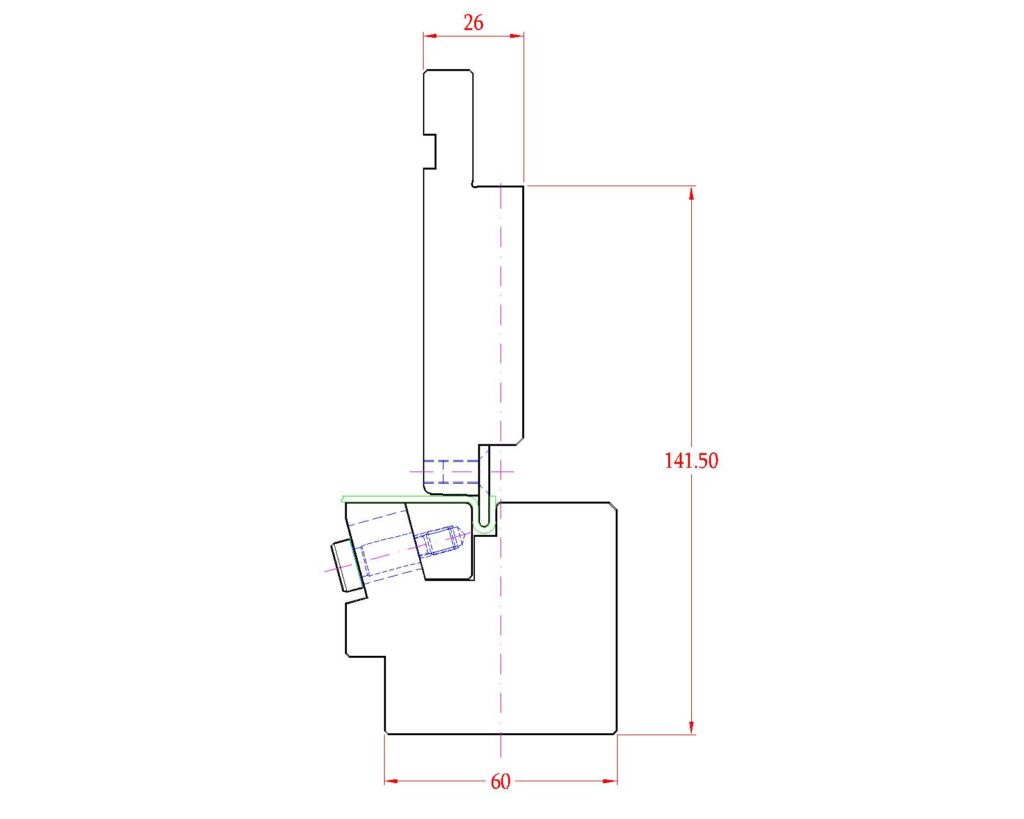

We were already clear about how the piece should be, but now we had to design a tool so that in one fell swoop it would make the piece in a “U” shape and, above all, to keep the parallelism. We opted to install a “wedge” in the tool, a widely used solution in our tools. This assures us the total guarantee of parallelism of the piece.

In the following sketch we can see the design plan of the tool, as we see with the upper and lower mooring type Promecam and with the wedge designed to guarantee the quality of the bend.

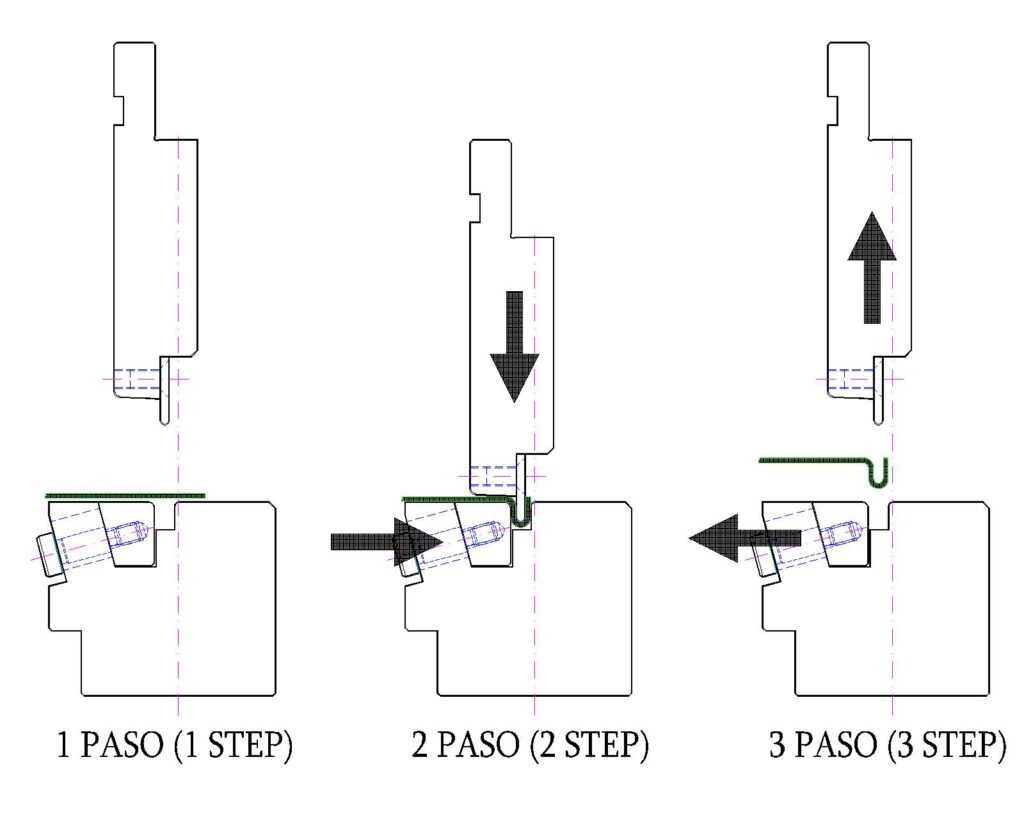

How does the tool wedge work?

The wedge designed for this tool has the function of ensuring the parallelism of the “U”. It works with pressure, that is to say when the punch (upper part of the special tool) presses on the die (lower part of the tool) the wedge pushes to its right, thus ensuring parallelism. When the punch stops making force, the wedge is withdrawn to the left and “releases the piece”, which for this same reason will be easier for us to extract from the same tool.

In the following sketch we can see this process in 3 graphic steps.

THE MANUFACTURING

We manufacture the special tool in a 1.000 m/m section, to make the shape of the part in one fell swoop and it has been made of C-50 steel tempered by induction in the work areas and rectified.

The mooring of both, the punch and the die of the special tool, was made with the mooring Promecam / Mebusa (or European tool system).

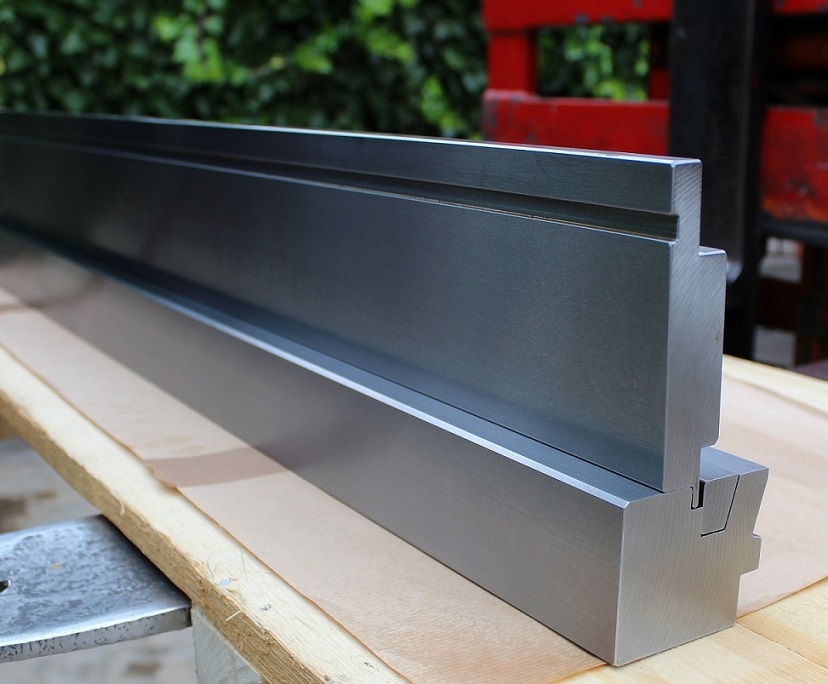

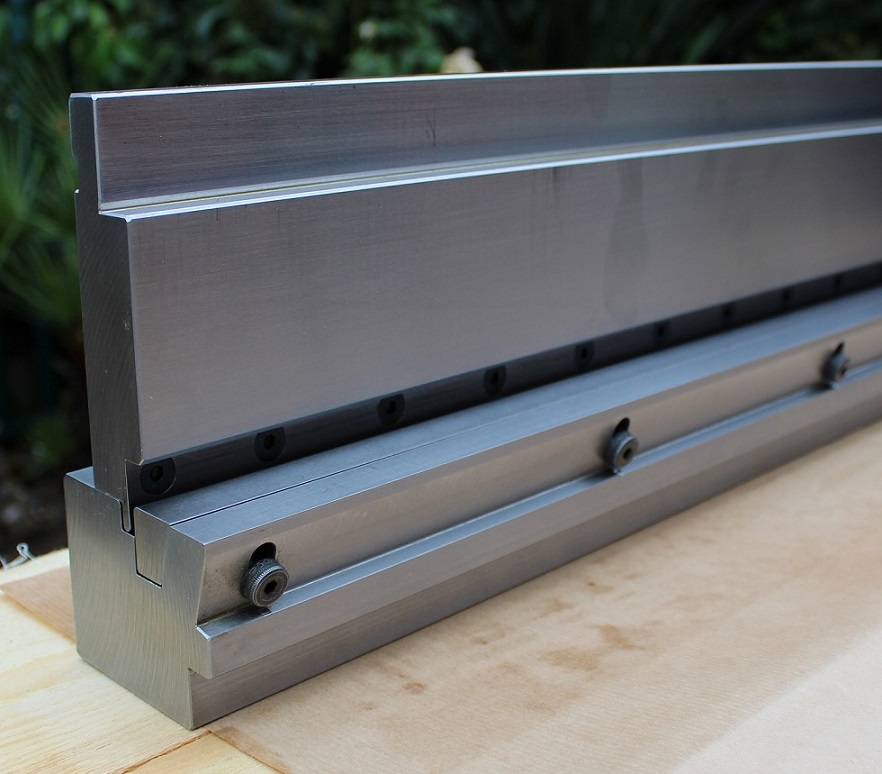

In the following photographs you can see the special tool already finished.

View of the front part of the special tool mod. 30.06

View of the rear part of the special tool mod. 30.06

In the second photograph you can see how the insert that has been installed in the punch is removable by means of screws, this has been done in case after the years there is a deterioration of the same and that it can be replaced by a new one easily and not harm the set of the special tool.

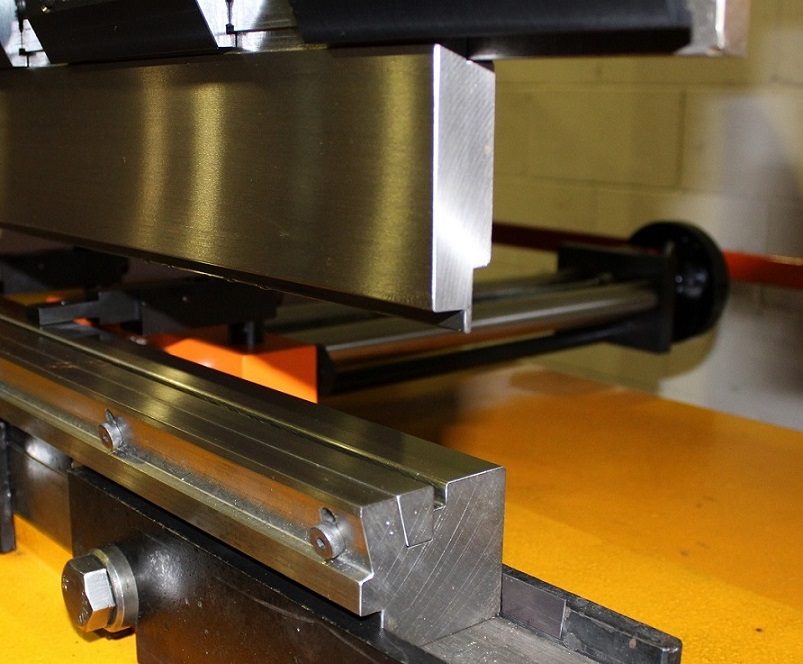

In the following photograph you can see the special tool 30.06 installed in our press brake MEBUSA to carry out the final tests.

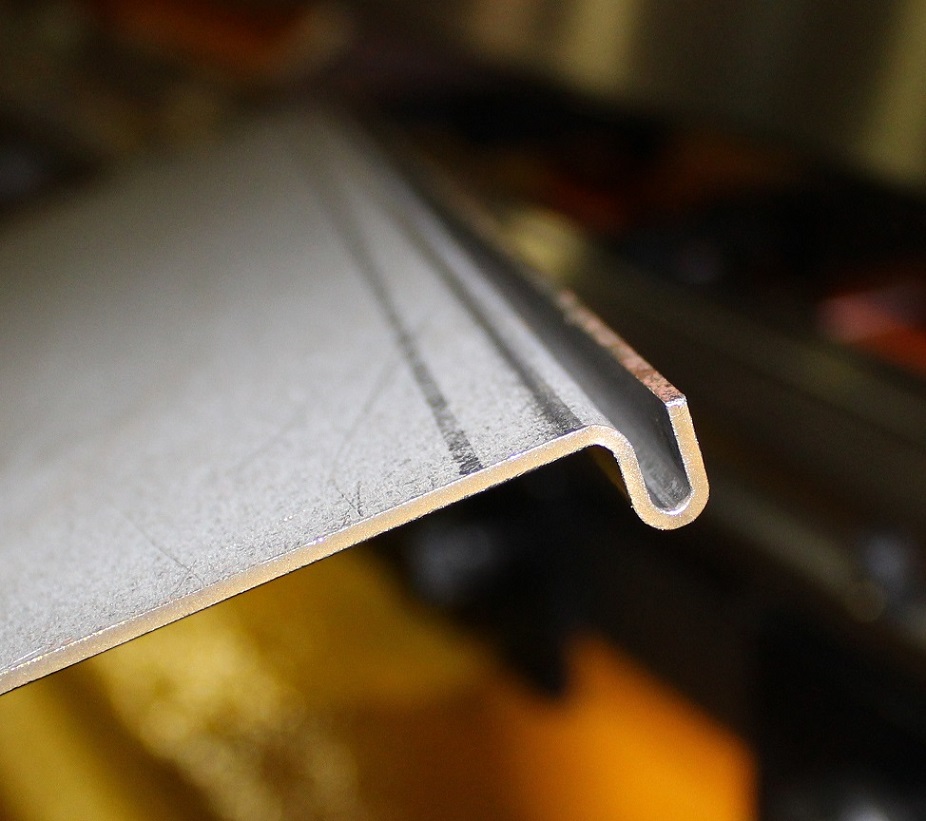

RESULT

The piece resulting from the test has been according to the design and with the walls of the “U” perfectly parallel, thanks to the wedge system installed in the tool. And so we can see it in the following image.

In the following video you can see the tool in full operation in our test press brake MEBUSA and you can also see the optimal result of the final piece.