METALMAQ manufactures a die of 3 meters with V = 200 m/m at 80º, to fold a thickness of 20 m/m in iron (with a resistance of 42/48 Kg/mm2) in a press brake AJIAL of 420 Ton and 3 meters.

THE DIFFICULTY OF THE PIECE

Our client is a boiler of large dimensions and needed to bend in his press brake AJIAL of 420Ton/3meters (with AJIAL-COLLY tie in the punches and a multi-vee die, therefore with a press brake equipped with a free table) sheet of 20 m/m of iron (with a resistance of 42/48 kg/mm2), but the die of his press brake currently only had a V with 100 m/m maximum.

SOLUTION ADOPTED BY METALMAQ

Our Technical Office made the calculation of the V necessary to make the bend and showed it to the client . As you can see in this post attached; https://metalmaq.shop/blog/en/tablas-de-plegado-de-chapa/ , here we teach how to do the calculation to know the appropriate die for each job. It is also important to see if the press brake has enough tonnage to run the piece in the length of 3 meters.

According to the table we see that to bend iron of 20 m/m (with resistance of 42 / 48kg), the ideal V will be of 200 m/m and with this die a force of 1278 Kn/m will be needed, that passed to Tons ( it should be divided by 10 ) is 127,8 Ton per meter, if the sheet is 3 meters, it will be 127,8 x 3 = 383,4 Ton, that is to say, to bend said sheet of 20 m/m in the V of 200 m/m and in 3 meters the press brake will need 383,4 Ton and as the press brake AJIAL of our customer is 420 Ton you can do the job without any problem.

RESULT –Special die with V=200 m/m entire in 3 meters – Metalmaq

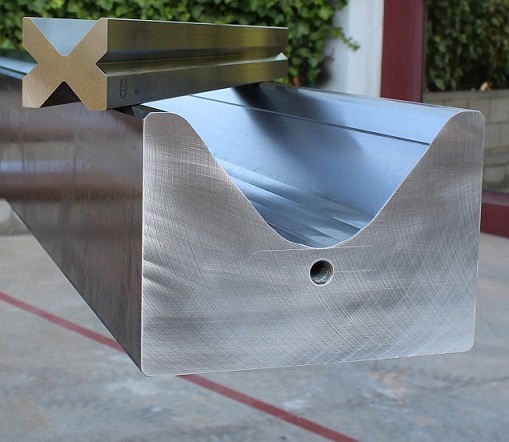

The result was the production of a die with a V of 200 m/m, entire at 3 meters, manufactured in steel 42CrMo4 tempered by induction in the working areas (to avoid the wear caused by the friction of the sheets when bending) and rectified, the die has a total weight of 670 kg in the three meters.

In the attached photos you can see how we have placed a standard die mod. 20.09 (one of the most sold) with dimensions of 60 x 60 m/m to compare the difference in dimensions with the manufactured die.

Special die with V of 200 m/m entire at 3mts, for sheet of 20 m/m

Special die with V of 200 m/m entire at 3mts compared with die 20.09

It can also be seen that the die has some projections in the area of the radius, this is done so that the friction of the sheet is not made in the entire section of the V, but only in the upper part, thus reducing so the necessary tonnage.

In the photos you can also see that the matrix was supplied with a threaded hole on each side to be able to handle it and move it more comfortably.