METALMAQ manufactures a special Adiprene Block with its container, for a press brake DURMA with mooring Promecam (or European tooling system).

THE PIECE

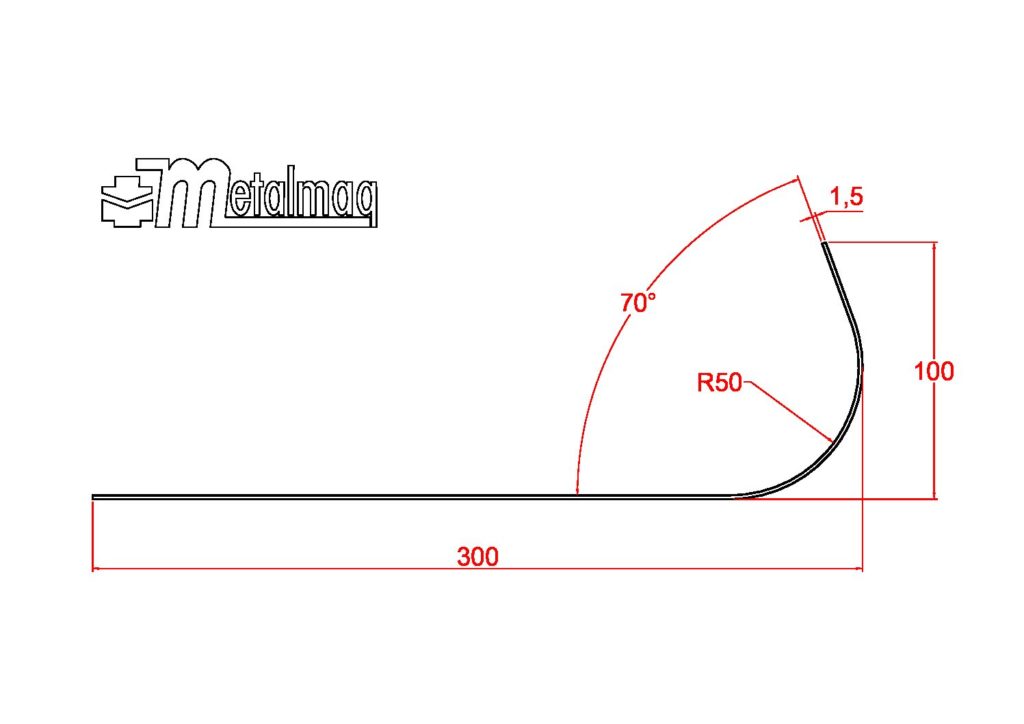

Our client is a large manufacturer of street furniture in France. He contacts us because he has to manufacture some 1,5 m/m stainless furniture, of 750 m/m length and has problems with a 50 m/m inner radius bend that must be folded at 70º. But it is also very important that the piece does not get scratched in the folding operation and for that reason he asks us for our best solution.

Sketch of the piece to be bended in 1,5 m/m stainless

THE SOLUTION

We àss the plan of the piece to our Technical Office and we see the possible solutions to adopt. At the end and proposing it to the client, it is decided to bend the piece with an Adiprene Block, but since the piece is quite large, the Adiprene must be made with special measures, as well as the Adiprene Container.

This solution is also chosen because the client does NOT want any type of mark on the piece .

Before starting the production, this demo video is shown to the customer so he can see how one works with an Adiprene Block ;

The manufacturinga of the Adiprene BLOCK and its Container

After several bending tests, finally the Adiprene Block is manufactured with a size of 150 m/m wide, 70 m/m thick and a length of 835 m/m. It is also decided to manufacture it with a central hole, oblong shaped, to decrease its resistance in the bending operation and thus decrease the tonnage needed by the press brake DURMA 120Ton/3mts, which the customer has.

In the following photos you can see the special Adiprene Block with its central hole, oblong-shaped and the special Container manufactured for said Adiprene Block.

Special adiprene block measuring 150x70x835 m/m

Special adiprene block, with central oblong-shaped hole

If we look at the manufactured container, we see in the lower part a central hole, this is done so that once the Block works it has a relief and the Protective film can be accommodated in said location, so as not to generate too much tension in the Adiprene block .

The manufacture of the punch with radius and its punch holder

The other difficulty of the piece is to define the radius of the punch to be manufactured.

Why is it a problem? The customer defines his piece with an inner radius of 50 m/m, but when working with radii, it must be folded to less degrees, so that the piece when it moves back it rests at the exact angle and radius. Therefore, the radius must also be considerably smaller, so that when the punch retracts and the piece is “opened”, the radius and the angle remain in its measure.

YOUR CAN SEE IT IN THE FOLLOWING ARTICLE HOW TO BEND LARGE RADIUS.

In the following photos you can see how the radio looks like and how it is adapted to a standard punch holder mod. 40.05. The other advantage is that if one day another piece must be manufactured, both the punch holder and the Adiprene Block can be used.

Punch holder + punch Radius 50 m/m and special adiprene block with container

Special assembly, to manufacture part with 50 m/m radius and without folding marks