METALMAQ manufactures a set of 15 punches with their clamps for panel bender TRUMPF

¿PUNCHES FOR PANEL BENDER?

Our customer is a manufacturer of profiles for the industry in general and is located in the North of Spain, a regular customer of our press brake tools and accessories, since he has 9 folding machines of brand TRUMPF and also has two panel benders of latest technology from the same brand.

For the latter, the customer asks us to manufacture spare parts of such panel benders and the response of our Technical Office is affirmative, but we need a sample or a detailed plan of what we must manufacture, since in the world of metal sheet panel benders, the tools are usually not standardized and each manufacturer adopts its own measures.

CUSTOMISED MANUFACTURING OF TOOLS

The customer passes the order to manufacture 15 punches for said panel bender, with a total length of 3.123 m/m and manufactured in steel 42CrMo4 tempered by induction in the work areas and rectified.

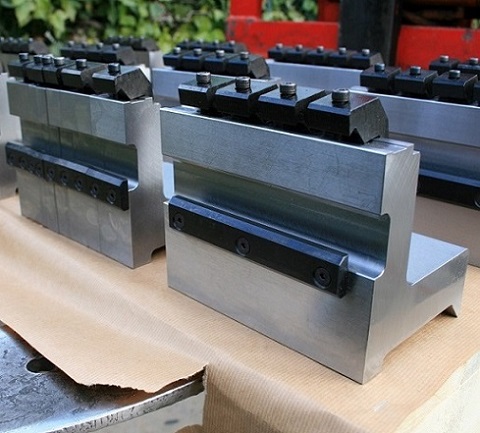

The final result, as you can see in the following photo, is optimal and our customer is very satisfied after the delivery of the punches for his Trumpf panel bender.

In the following view you can see the side detail of the punches, with the upper clamps made of normal steel and black-painted.

In the following view you can see the back detail of the punches, with the upper clamps and also with the back clamps also made of normal steel and black-painted .

¿WHAT IS A METAL SHEET PANEL BENDER?

The panel bender is a machine to bend metal sheet, but unlike the press brake, in it you can work with the sheet completely flat and it is only the fold that makes the movement . They are much more expensive than conventional hydraulic press brakes and with less versatility, but for the sector of panels or doors, the operator avoids the movement to always lift the sheet and thus gains agility in certain jobs.

The most common brands of panel benders are; Ras, Salvagnini, Trumpf, Danobat, Schröder, Cidan, Thalmann, among others .

As always you should value what you get more account, if conventional hydraulic bending or the panel bender. Depending on the work to be done, this will mark the most appropriate option to follow and depending on the workload and the type of the bends will be decided between the two options. The market is very clear on this issue; for each 1000 hydraulic press brakes there are between 1 or 2 panel benders, but this does not mean that the latter give bad results, simply that the former are more diversified, there are more manufacturers, there are more ranges of prices and allow more solutions.

PRINCIPLE OF OPERATION PRESS BRAKE VS PANEL BENDER

PRESS BRAKE: The bending force applied in the center of the metal sheet is generated when the moving part (punch) descends against the fixed part of the press (die).

PANEL BENDER: The deformation occurs due to oscillations of the blade while the clamp blocks the sheet during work.

Thanks for posting this info. I just want to let you know that I have checked out your site and I found it very interesting and informative.

Thank you very much for your comment, this helps us to continue helping !!