Punch for press brake Beyeler-Bystronic

Metalmaq manufactures customized punches, in this case 16 meters of special punch with Beyeler mooring and total height of 440 m/m for press brake Bystronic of 16 meters.

Press brake Bystronic with mooring Beyeler RF-A

Our client makes large structures, up to 16 meters length for infrastructures of public works and presents us a set of parts that he wants to start producing in his Bystronic press brake with Beyeler RF-A mooring. Our Technical Office studies the possibility of being able to make all his pieces with only one type of punch.

Punch manufactured by Metalmaq

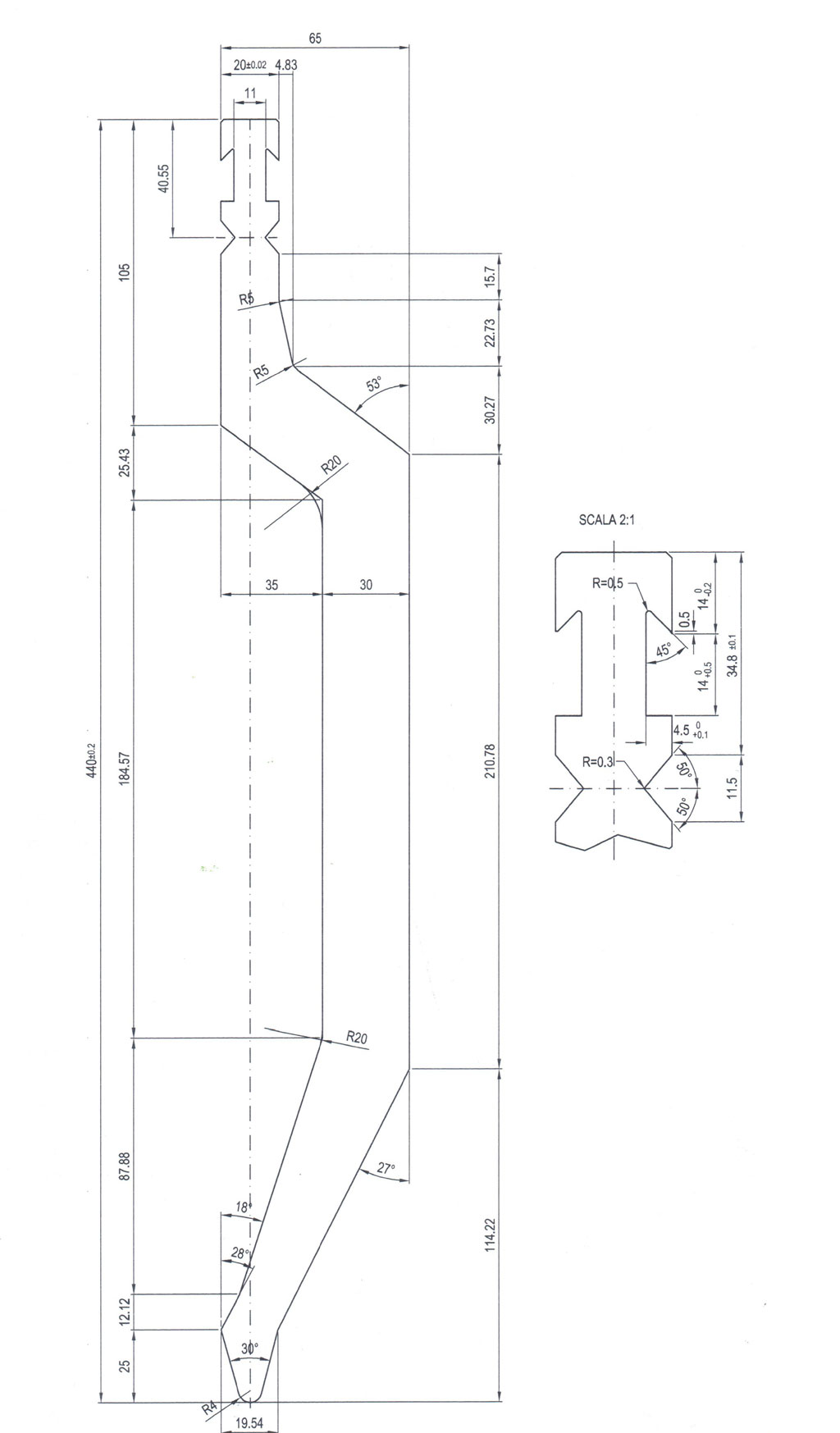

Our Technical Office designs a punch with a considerable scale, 440m/m height dimensions!, as you can see in the attached sketch. With a quite pronounced radius of 4 m / m, since the pieces are of a remarkable thickness and thus we guarantee the durability of the tooling. The punch has an internal hollow, which we call “goat’s foot” to be able to house the inside of the folded piece, also the punch is designed with an angle of 30º, since it is necessary to be able to make a set of pieces.

Mooring Beyeler RF-A

In the plane you can also see the difficulty of manufacturing Beyeler mooring, which is mooring type RF-A, for the frontal hydraulic mooring in press brakes of this type. This mooring has the advantage that the punches are mounted frontally in the press brake and once the hydraulic system is closed, centered and aligned automatically, being ready to start working.

Result: Special punch with Beyeler mooring for Bystronic press brake

As you can see in the photo that opens the news, the result is spectacular. It has been manufactured 16 meters of special punch with a height of 440m/m and a really particular design to be able to make the pieces proposed by the client. The mooring is Beyeler to be able to fit in a folder of the Bystronic-Beyeler brand of our client The steel used for the manufacture of these folding tools is known as 42CrMo4 steel and has also been tempered by induction and rectified, which gives a hardness in the work areas of 52-58 HRC, thus ensuring the durability of the bending punch over time and its almost zero wear when bending the sheets that require it.