Metalmaq manufactures a 2,5-meter tool for closing and crushing metal sheet, with double-acting pneumatic drive and with a “Wila” type die holder on the upper part.

Close and crush sheet

Our customer is a world leader in vertical transport systems. And he consulted us about the need to equip one of his press brakes with a system that should allow him to close and crush metal sheet and also put a different V in the die according to the production. Also this tool had to serve as a matrix when the closing operation was not used, since many of its pieces carry a “closing”, but later they carry several normal folds at 90º and 50º

¿What is closing a piece?

We understand by closing the operation of closing flanges in metal sheet. For more information about the closing of pieces you can visit this entry in our section of bending solutions.

Solutions to crush metal sheet

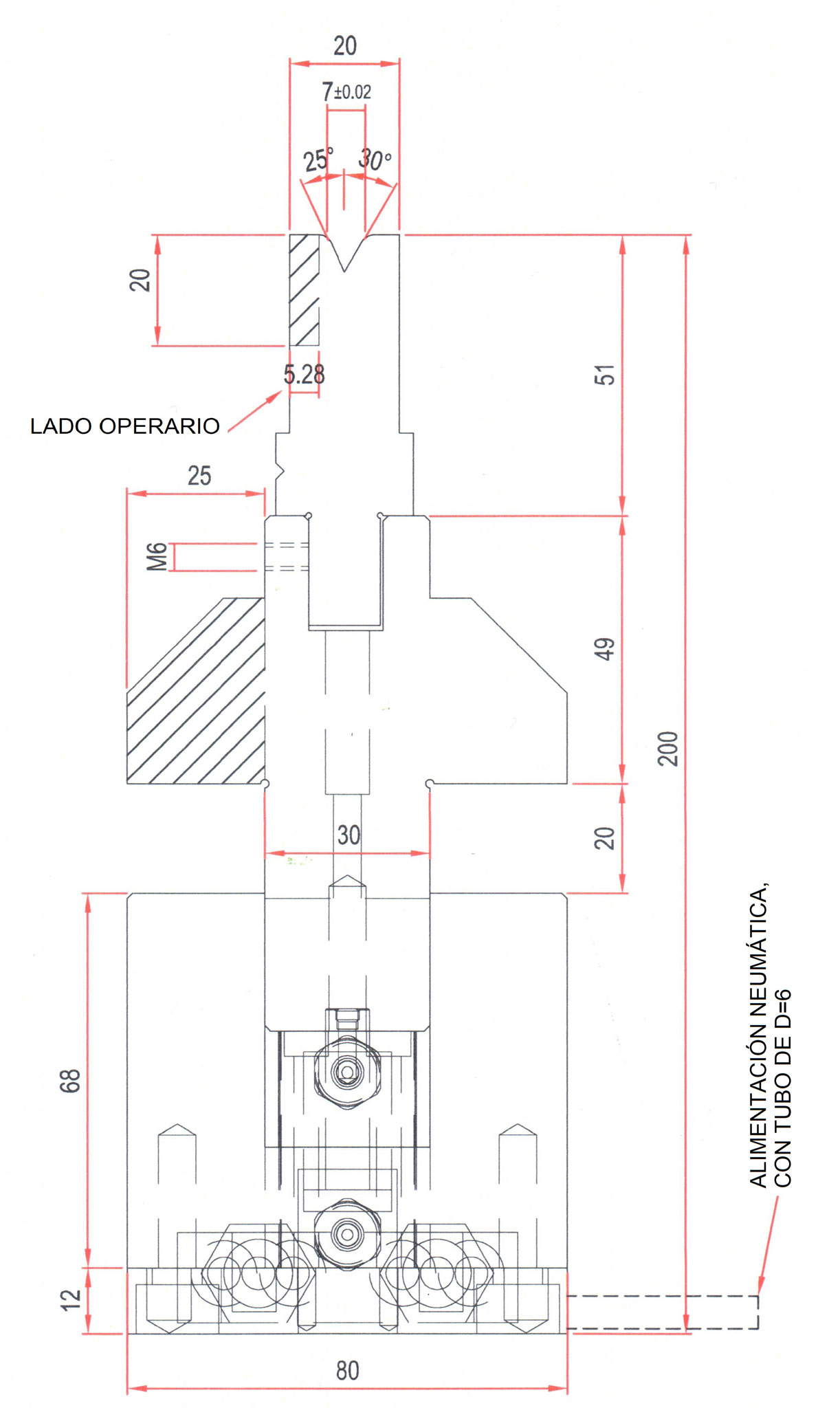

Our Technical Office, with the experience after several designs, opts for the best solution for the client, an all-in-one tool !!! Before starting up with the production and the tests, we send a design with the pertinent technical explanations to our client so that he can evaluate our proposal. In the image we can see the plane of the special pneumatic die holder for press brake sent to our client.

Pneumatic die holder with double effect cylinders

The design consists of a pneumatic die holder with double effect cylinders, that is to say that they need a sign to both raise and lower the tool. The customer told us that he wanted to direct this drive from the Numerical Control of his press brake, reason why we advised him this system.

Working and characteristics of the pneumatic die holder

- When the tool is open you can put the sheet in the gap that opens and with the descent of the press brake you get to close the sheet.

- When the tool is closed the tool behaves like a die holder, since in the upper part the tool was adapted to be able to mount wila-beyeler type dies according to the need of each metal sheet design. Threaded screws were installed on the side for the assembly of fractioned dies, avoiding like this their possible lateral movement.

- Finally, a fairly straight punch was also designed, but with some neckline to “avoid” some piece sent, the punch was designed with a tie for AJIAL-COLLY press brake as it is the tie that has our client’s press brake.

- Both punches and dies and even the tool were manufactured with some “entries” (see attached picture) to save some tabs of the pieces of our client.

The client before this explanation of our technicians accepts the design as good and we start the tests to later start the production of the tooling for the press brake in question.

Video pneumatic die holder for press brake: working of the double effect cylinders

Final result

After the tests in our facilities with sheets and drawings of the client, we take for good the manufacture and send the tools to our client to start the production. The tool, the dies and the punches were manufactured in steel 42CrMo4 tempered by induction and rectified ensuring so the quality, durability and low wear of the whole set.

Detail of the punch