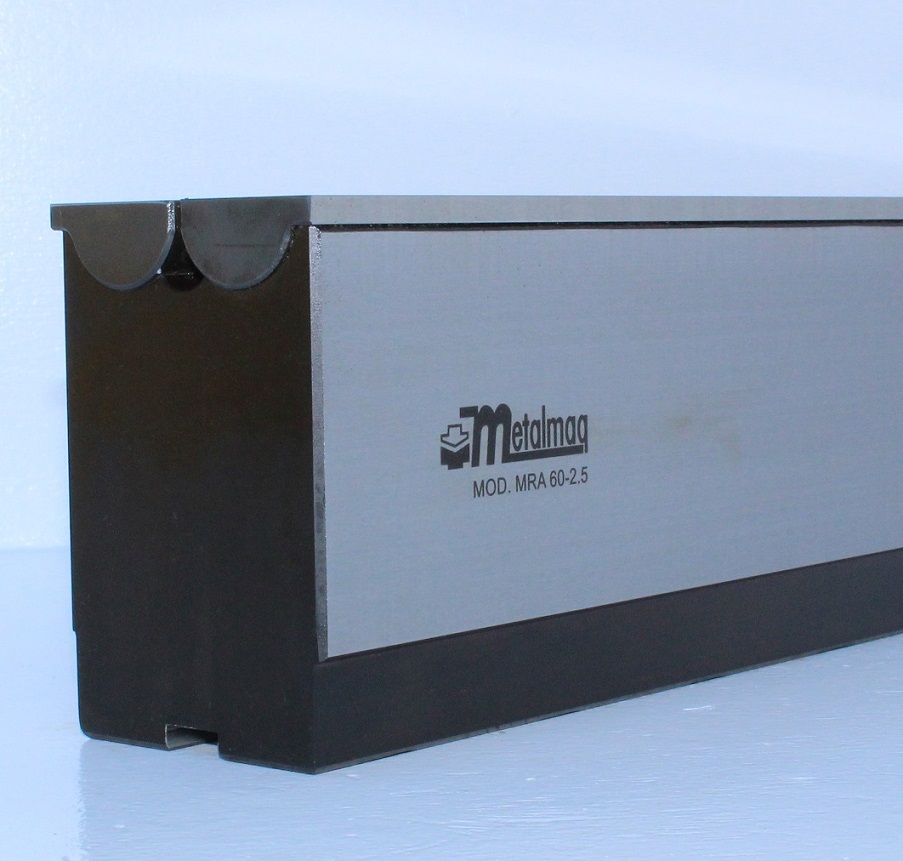

METALMAQ presents a NEW die model MRA (WING BEND) for press brakes, the MRA 60-2,5 with mooring Promecam and its MRA 100-2,5 variant for mooring Trumpf / Speed / Wila.

THE DIFFERENT DIE MODELS MRA (WING BEND)

Until now, the range of dies MRA (WING BEND) consisted of four models and each model had three types of mooring: the Promecam, the Trumpf / Speed type and finally the mooring Beyeler / Wila.

The four models are characterized above all by the capacity of the metal sheet to work and by their recommendations that we are going to analyze here;

– Die MRA 60-1, MRA 100-1 and MRA 55-1

Recommended thickness from 0,5 to 1,5 m/m (possible 2 m/m Fe)

Minimum angle of 35 °

Equivalence with V=8 m/m

Maximum tonnage 100 Ton/mt

– Die MRA 60-2, MRA 100-2 and MRA 55-2

Recommended thickness from 2 to 3,2 m/m (possible 4 m/m Fe)

Minimum angle of 60º

Equivalence with V=15 m/m

Maximum tonnage 150 Ton / mt

– Die MRA 60-3, MRA 100-3 and MRA 55-3

Recommended thickness from 4 to 6 m/m (possible 8 m/m Fe)

Minimum angle of 50º

Equivalence with V=35 m/m

Maximum tonnage 150 Ton / mt

– Die MRA 60-4 and MRA 90-4

Recommended thickness from 6 to 12 m / m (possible 16 m/m Fe)

Minimum angle of 75º

Equivalence with V=85 m/m

Maximum tonnage 300 Ton/mt

WHAT ADVANTAGES DO MRA DIES (WING BEND) HAVE OVER NORMAL PRESS BRAKES DIES?

The dies MRA (WING BEND) have many advantages over normal press brake dies and these are the main ones:

– Free of marks on the metal sheet

As it is a rotating system, the metal sheet does not suffer drag in the area of the radius of the die, with the MRA (WING BEND) the sheet always slides flat and therefore the marks almost disappear

– No contamination of the material to be bended

As there are no marks in the bending area, the sheet is not contaminated when we are bending stainless material (remember that the contamination is caused by ferrous particles adhered to the stainless steel in the bending operation)

– Realisation of very small eyelashes

By having a rotation system (patented) they allow to make very small tabs, which if they were made in standard dies should be larger

– Holes near the bending area are NOT deformed

With standard dies the holes near the bending area are deformed. With dies MRA (WING BEND) they do not deform, as long as they are in the flat area of the metal sheet and do not enter the radius of the material

– Manufactured in steel 42CrMo4 and tempered by induction

The dies MRA (WING BEND) are manufactured with the best materials and treatments so that they have a very long useful life

In the following video of the die MRA 60-3 we can see all these points that we detailed;

WHY A NEW DIE MODEL MRA(WING BEND)?

As can be seen in the previous section, customers told us that there was a lot of space between the MRA 60-2 and the MRA 60-3, especially when they wanted to speed up measurements (minimum wings, distance of the holes near the fold, etc.) and that is why it was decided to create the new MRA 60-2,5 to expand the benefits of the two mentioned matrices.

And these are the main features of the MRA 60-2,5 and the MRA 100-2,5;

Recommended thickness from 2 to 5 m/m (possible 6 m/m Fe)

Minimum angle of 50º

Equivalence with V=25 m/m

Maximum tonnage 250 Ton/mt

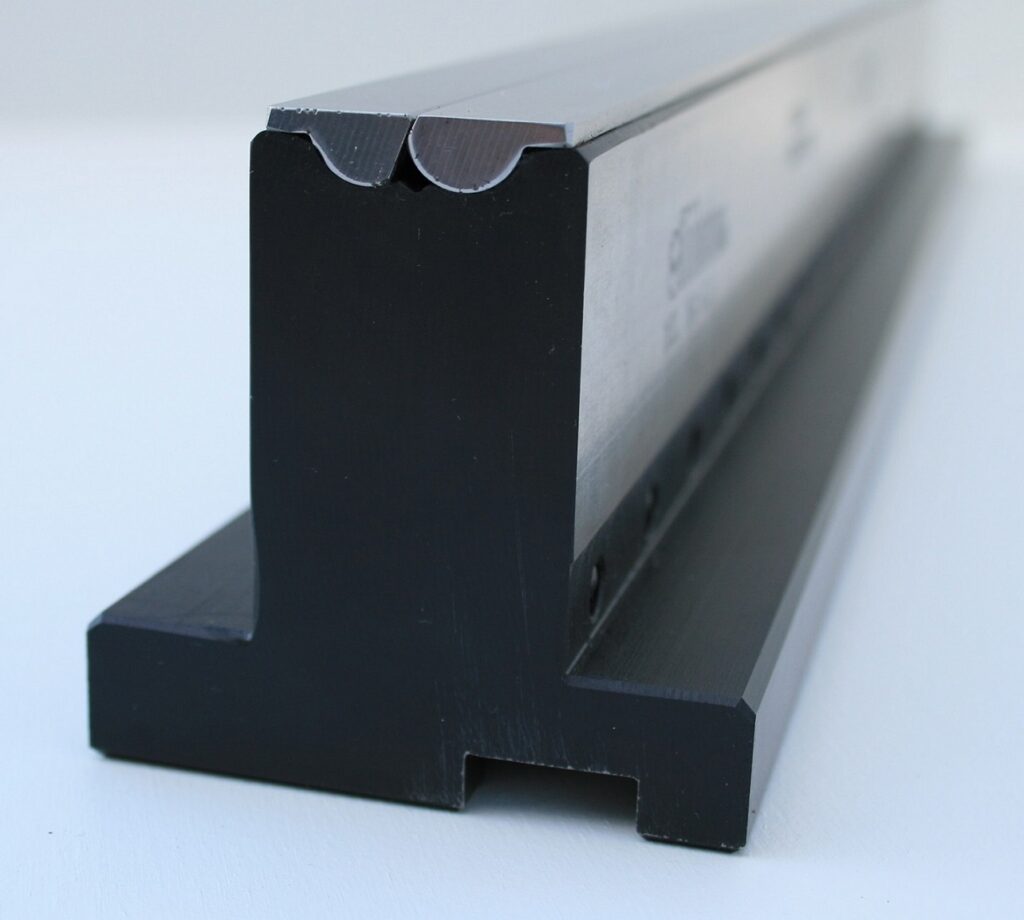

Die MRA 60-2,5, side view of the die with accompanying rollers

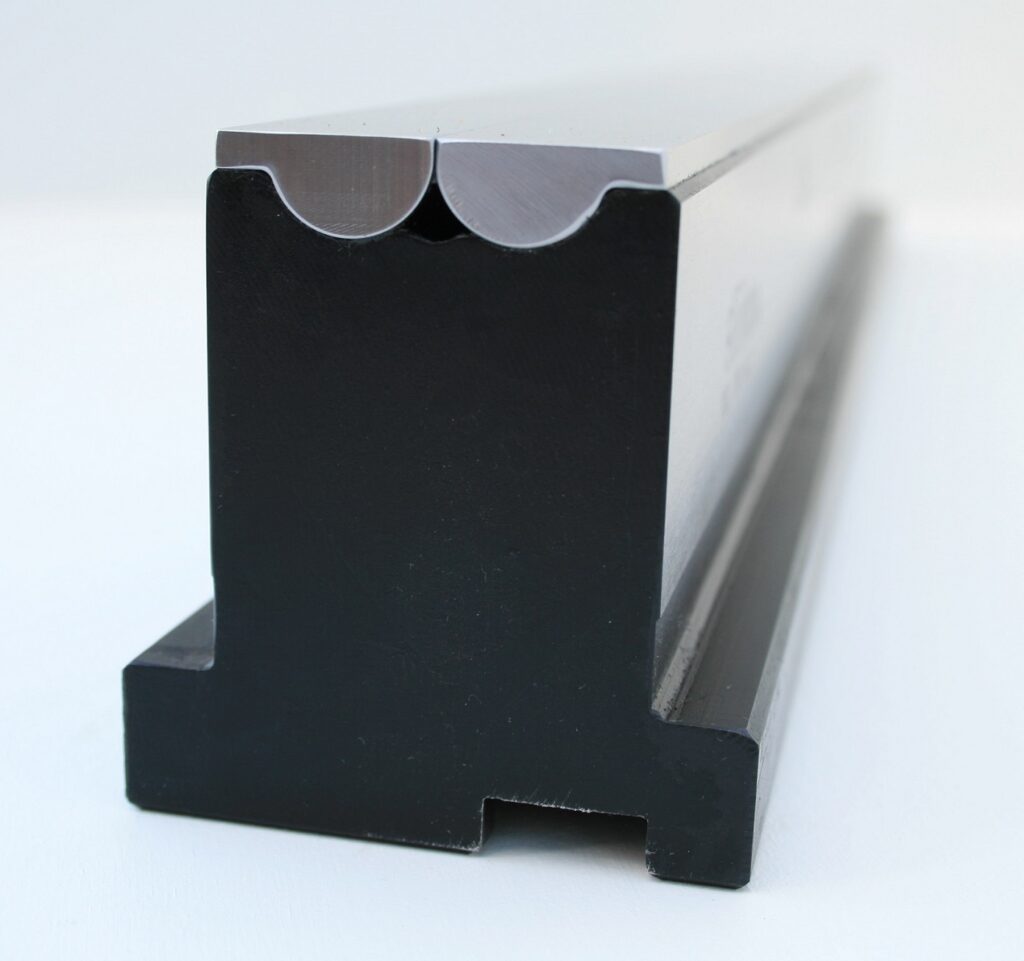

Die MRA 60-2,5, profile view of the die with accompanying rollers

THE RESULT

As you can see in the next video, the die MRA 60-2,5 has some characteristics that make it unique for certain jobs:

WHERE DO I BUY THIS NEW DIE MRA (WING BEND)?

The purchase is the easiest part of this process, in our ONLINE SHOP with a simple CLICK it will arrive at your facilities very well packed, quickly and with maximum security.