The lacquering of aluminum consists of the electrostatic application of a powder paint to the surface of the aluminum. The paints used for this finish are polyester or polyurethane resins and this gives them great resistance to UV rays, atmospheric agents and corrosion.

For the aforementioned reasons, lacquered aluminum is a great material, but when bending it in a metal sheet press brake, two questions must be taken into account if we want to avoid, as far as possible, that in this operation the material is marked or cracked.

Now we are going to how to avoid bending marks on lacquered aluminum?

CHOOSING THE BEST PUNCH

Aluminum itself is usually a brittle material and tends to crack in the bending operation and if it is lacquered on top, these marks are usually seen more.

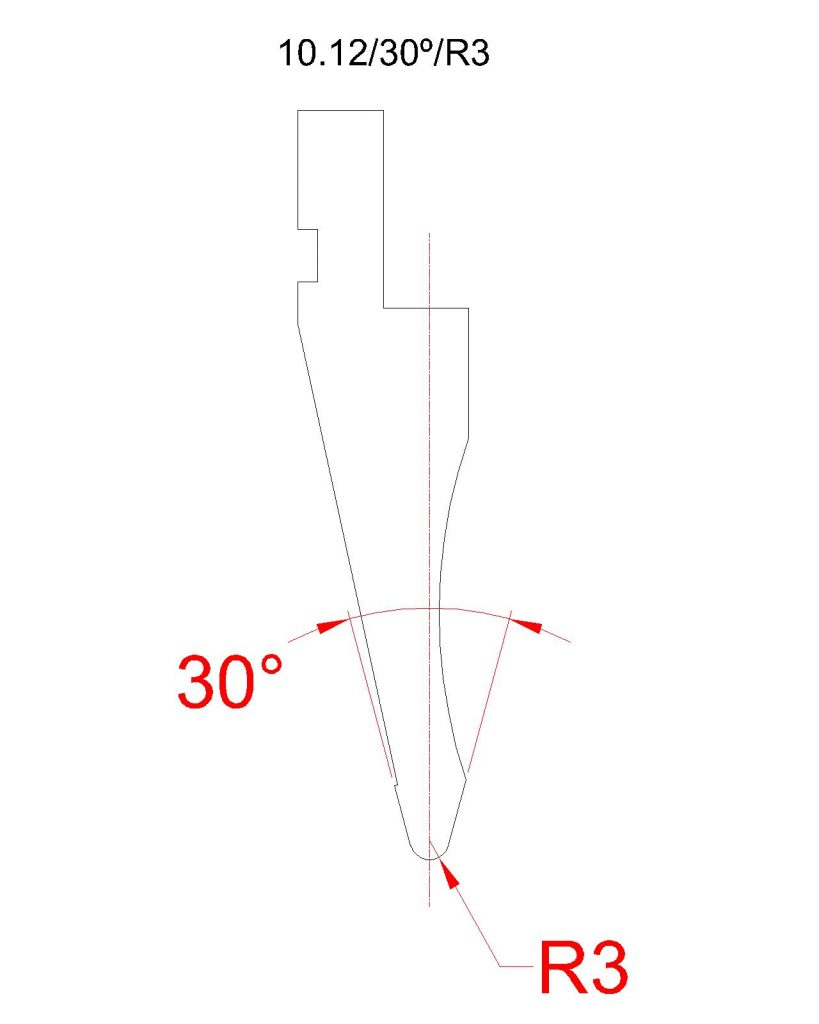

Therefore, we must choose a punch with a little more radius than usual. If metal sheet is usually bended with punches of radius of 0,8 m/m, in the case of bending lacquered aluminum, the recommendation is to use punches with radii of 2 or 3 m/m at the tip, this will make the piece have more outer radius, will “soften” its bend and will avoid much (or almost entirely) the marks or cracks in the Aluminum. Obviously, we recommend doing small tests before making an important series, because depending on the lacquer finish, the fiber direction and its type, there may be differences in the behavior of the Aluminum.

In the following sketch we see an ideal punch for bending Lacquered aluminum, it is the punch mod. 10.12/30º/R3, which is a 30º punch with a radius at the tip of 3 m/m.

ELECTION OF THE DIE

The election of the die will depend on the thickness of the Aluminum to be bended (see Bending Table), but the important recommendation is to use a Protective Film on top of the die, to avoid friction and the marks caused in the bending operation. Since in this operation, the friction of the sheet with the die causes inevitably small marks and if the material is delicate we must take even more precautions.

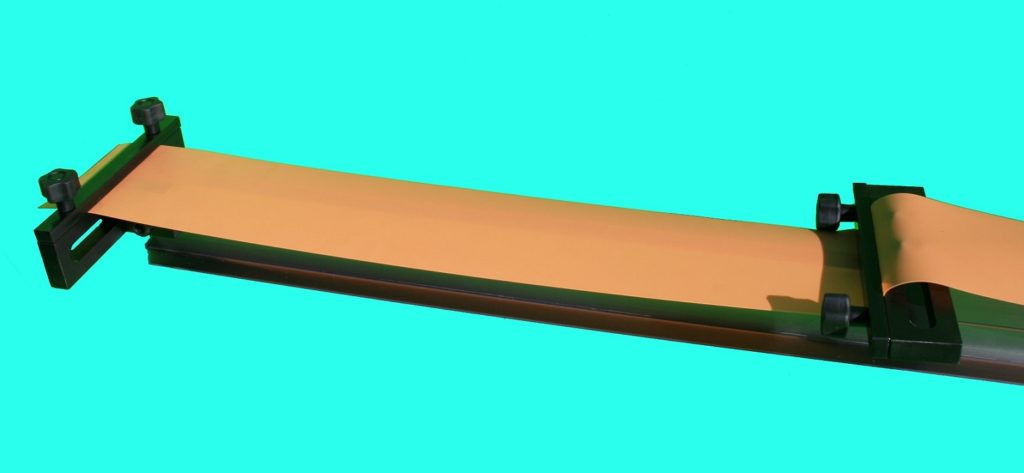

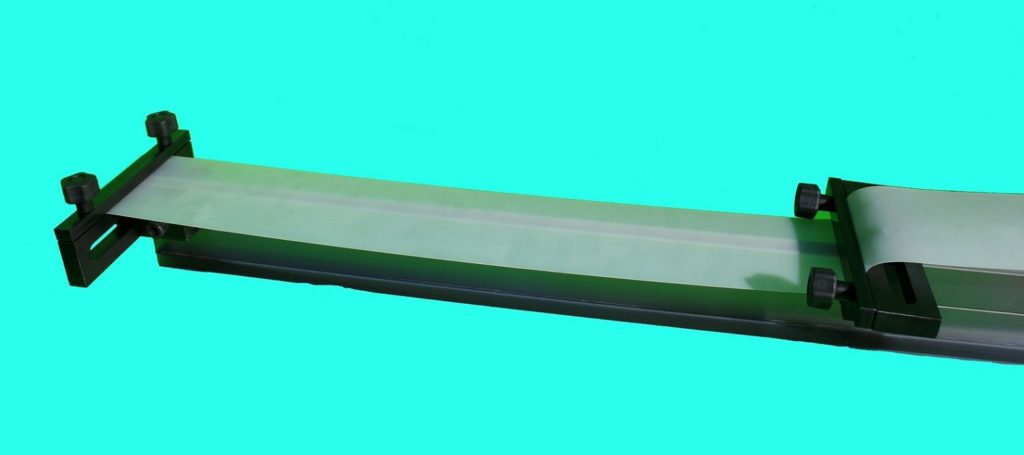

In the following photos you can see different Protective Films installed on top of a die and ready to bend delicate materials, such as lacquered Aluminum.

Protective film USA 0,5 m/m, protective film “without marks” of press brake

Installation in die of the Polyurethane Rubber 0,8 m/m

A VIDEO AS A BEST EXAMPLE

In the following video we will see how a 1 m/m Aluminum is bended and lacquered in black.

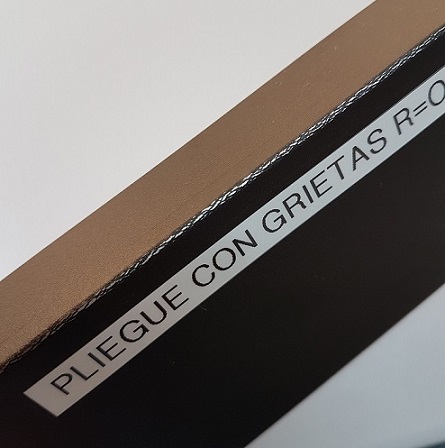

In the first part of the video it is bended with a very common punch, mod. 10.12/35º, but with a radius of 0,8 m/m and a die with V of 8 m/m and without any type of protection. The result is a bend where cracks are observed in the outer radius and also the typical bending marks.

In the second part of the video we see how it bends with the punch mod. 10.12/35º/R3 with a radius of 3 m/m, the Protective Film has also been installed on top of the die with the V of 8 m/m, in this case the Protective film Goma USA. The result when bending the same lacquered Aluminum is completely different, the bend has been perfect!!, without marks or cracks in the Aluminum.